Anti-seepage castable

A castable and anti-seepage agent technology, which is applied in the field of anti-seepage castables, can solve the problems of easily polluted aluminum liquid components, furnace lining damage, and poor wettability of aluminum liquid, so as to weaken the penetration ability, improve strength, and optimize anti-seepage performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

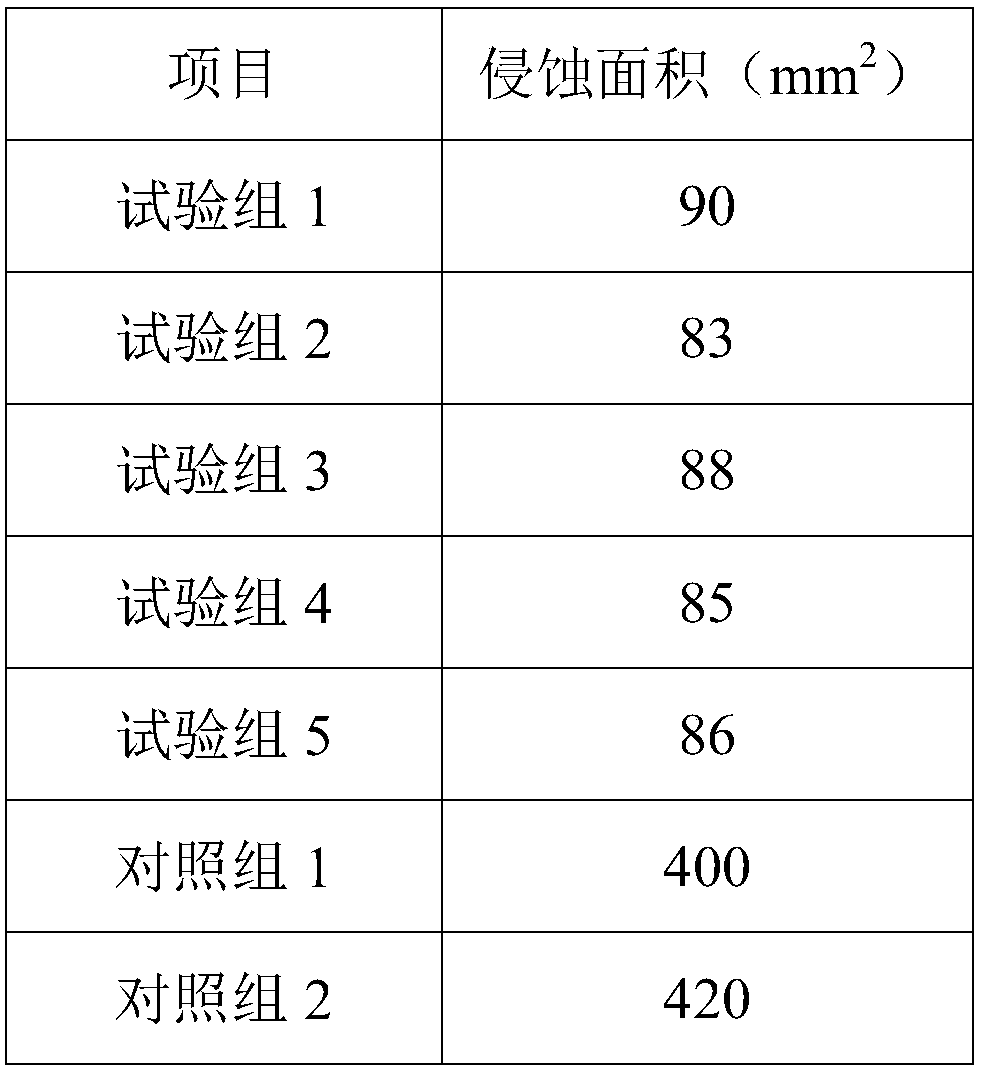

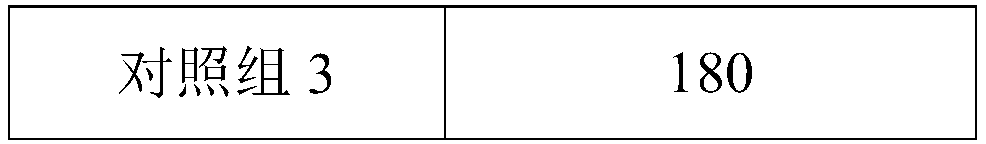

Examples

Embodiment 1

[0017] An anti-seepage castable, the raw materials of which include by weight: 53 parts of coke gemstones, 21 parts of magnesia fine powder, 8 parts of barium feldspar powder, 10 parts of cement, 2 parts of anti-seepage agent, 9 parts of nanometer potato powder, potassium feldspar 4.5 parts of fine stone powder, 4 parts of silicon carbide, 9 parts of calcium hexaaluminate, 7.5 parts of sodium aluminate, and 0.1 part of 2-morpholineethanesulfonic acid.

Embodiment 2

[0019] An anti-seepage castable, its raw materials include by weight: 76 parts of coke gemstone, 13 parts of magnesia fine powder, 14 parts of feldspar powder, 4 parts of cement, 7 parts of anti-seepage agent, 3 parts of nano-potato powder, potassium feldspar 9 parts of fine stone powder, 1.5 parts of silicon carbide, 16 parts of calcium hexaaluminate, 2.5 parts of sodium aluminate, 0.6 parts of 2-morpholineethanesulfonic acid;

[0020] Wherein, the particle composition of the burnt gems is as follows: 40% of particles with a particle diameter of 6-3mm, 30% of particles with a particle diameter of 3-1mm, and 30% of particles with a particle diameter of 1-0mm.

Embodiment 3

[0022] An anti-seepage castable, its raw materials include by weight: 65 parts of coke gemstone, 17 parts of magnesia fine powder, 11 parts of feldspar powder, 7 parts of cement, 4 parts of anti-seepage agent, 6 parts of nano-potato powder, potassium feldspar 6 parts of fine stone powder, 2.5 parts of silicon carbide, 12 parts of calcium hexaaluminate, 4.5 parts of sodium aluminate, 0.4 parts of 2-morpholineethanesulfonic acid;

[0023] Wherein, the particle composition of the burnt gemstones is: 40% of particles with a particle size of 6-3mm, 30% of particles with a particle size of 3-1mm, and 30% of particles with a particle size of 1-0mm;

[0024] The anti-seepage agent is composed of barium sulfate, chromium oxide and anti-seepage aid according to the mass ratio of 1:0.8:0.7;

[0025] The preparation method of the anti-seepage auxiliary agent is as follows: taking iron powder and titanium nitride powder and mixing evenly, sintering, and heat preservation to obtain the anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com