Printing ink cleaning agent

A cleaning agent and ink technology, applied in the field of cleaning agents, can solve the problems of blanket and ink roller corrosion, flammability and explosion, etc., and achieve the effect of increasing wetting angle, low volatility, and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

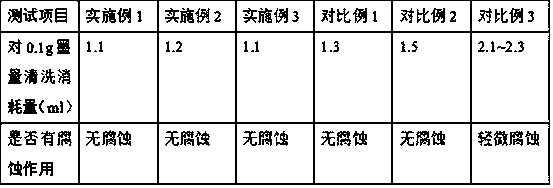

Examples

preparation example Construction

[0029] The preparation method of biological emulsifier comprises the steps:

[0030] S1. Take thermophilic Bacillus oleophilus, add yeast extract, glucose, and water according to the mass ratio of 2:3:5:7, mix well and stir to obtain bacterial liquid A, and take bacterial liquid A to inoculate with an inoculation amount of 5-10%. Cultivate in the culture medium with an air shaker at 130~150r / min at 55~60°C for 5~6 days to obtain bacterial liquid B, take yeast powder and add sterile water at a mass ratio of 1:3 to obtain yeast liquid, press Inoculate 5-10% of the inoculum yeast liquid into the fermenter, and cultivate it at 22-28°C for 45-48 hours to obtain a culture. Take bacterial liquid B and inoculate it into the fermenter with an inoculum of 5-10%. Cultivate at 28°C for 45-48 hours to obtain the crude emulsifier;

[0031] S2. Take the crude emulsifier and centrifuge it at 3000~4000r / min for 20min to remove the precipitate, refrigerate at 2~5°C, filter it with a 0.25μm fil...

Embodiment 1

[0034] Cetearyl dimethyl betaine: purchased from Shanghai Shengxuan Chemical Co., Ltd.

[0035] D-limonene: purchased from Jiangsu Fengze Native Animal Products Co., Ltd.

[0036] Thermophilic Bacillus oleifera: purchased from Suzhou Beina Chuanglian Biotechnology Co., Ltd.

[0037] The composition of the medium includes: 1% yeast extract, 2% peptone, 2% KH2PO4, 2% K2 HPO4, 2% beef extract, 1% NaCl, 0.5% MgSO4, 1% CaCl2, 10% normal ten Hexane, 78.5% H2O, sterilized at 121°C for 30 minutes to obtain the culture medium.

[0038] Surfactant: Sodium fatty alcohol polyoxyethylene ether sulfate and sodium secondary alkylsulfonate are mixed in a mass ratio of 2:3.

[0039] Auxiliaries: Paraffin wax, magnesium oxide, magnesium lauryl hydroxystearate, and castor oil are mixed in a mass ratio of 3:1:1:1 to obtain the auxiliaries.

[0040] Alkaline solvent: mix sodium carbonate and ethylenediamine at a mass ratio of 4:1 to obtain an alkaline solvent.

[0041] Corrosion inhibitor: Mix...

Embodiment 2

[0048] Cetearyl dimethyl betaine: purchased from Shanghai Shengxuan Chemical Co., Ltd.

[0049] D-limonene: purchased from Jiangsu Fengze Native Animal Products Co., Ltd.

[0050] Thermophilic Bacillus oleifera: purchased from Suzhou Beina Chuanglian Biotechnology Co., Ltd.

[0051] The composition of the medium includes: 1% yeast extract, 2% peptone, 2% KH2PO4, 2% K2 HPO4, 2% beef extract, 1% NaCl, 0.5% MgSO4, 1% CaCl2, 10% normal ten Hexane, 78.5% H2O, sterilized at 121°C for 50 minutes to obtain the culture medium.

[0052] Surfactant: Sodium fatty alcohol polyoxyethylene ether sulfate and sodium secondary alkylsulfonate are mixed in a mass ratio of 2:3.

[0053] Auxiliaries: Paraffin wax, magnesium oxide, magnesium lauryl hydroxystearate, and castor oil are mixed in a mass ratio of 3:1:1:1 to obtain the auxiliaries.

[0054] Alkaline solvent: mix sodium carbonate and ethylenediamine at a mass ratio of 4:1 to obtain an alkaline solvent.

[0055] Corrosion inhibitor: Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com