An assembled lattice frame beam

A frame beam and assembled technology, which is applied in the direction of planting substrate, infrastructure engineering, plant protection cover, etc., can solve the problems of spraying substrate waste, vegetation is difficult to survive, lattice beams are not suitable for construction, etc., and achieve good anti-tilt performance , good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following takes the protection of ecological greening on a high and steep slope in a community in Yanji City as an example. The specific plan is as follows:

[0036] 1. Support design scheme

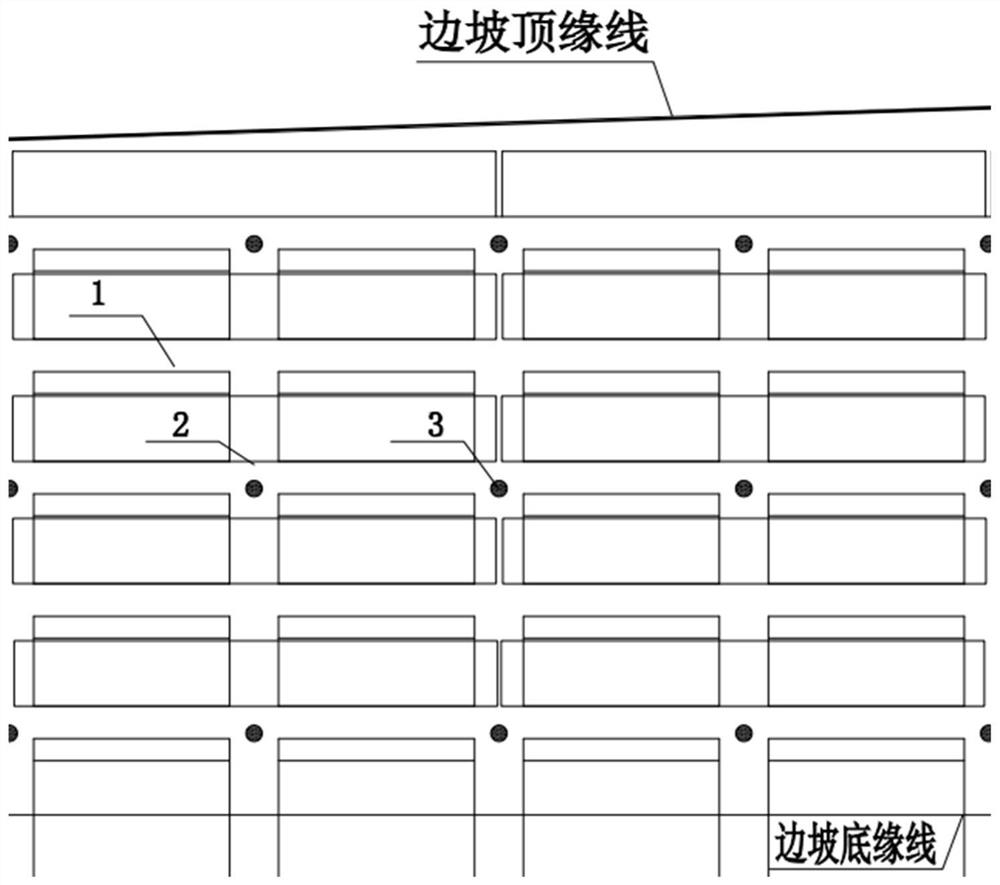

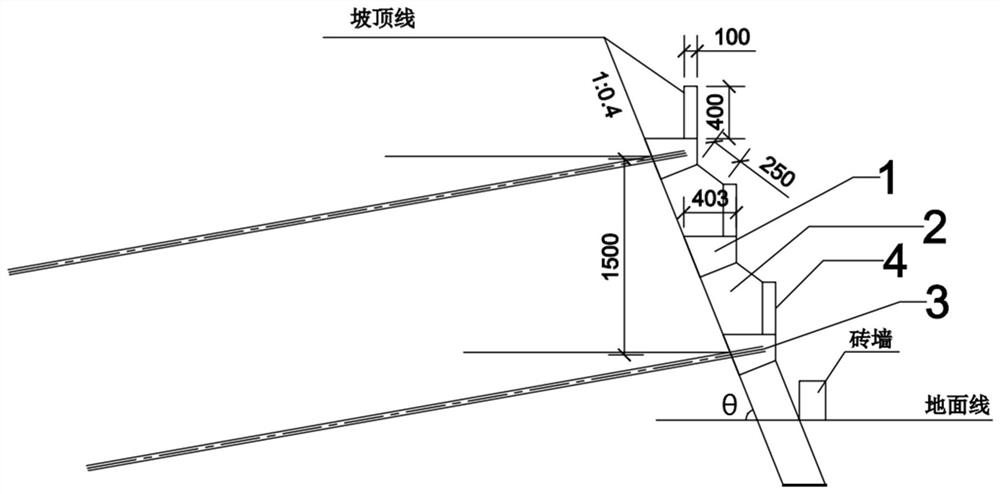

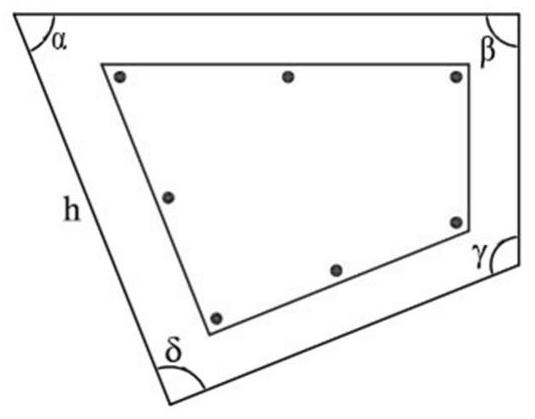

[0037] The lattice frame beam adopts reinforced concrete structure, the horizontal spacing of vertical beams is 1.5 meters, and the vertical spacing of cross beams is 0.75 meters. The height of the vertical beam adopts a variable section, and the width of the vertical beam is 0.3 meters. The height of the beam adopts the same section, and the height of the beam is 0.34 meters;

[0038] The lattice frame beam is provided with an expansion joint every 15 to 20 meters along the longitudinal direction, and the width of the expansion joint is 0.02 meters.

[0039] The baffle adopts a reinforced concrete structure with a thickness of 0.1m and a height of 0.4m. The length of the plate 5 is 1.745 meters, the length of the baffle 6 is 3.575 meters, and the length of the baffle 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com