Cleaning device for deep pile core soil of prefabricated pipe pile

A prefabricated pipe pile and cleaning device technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult and difficult to remove pile core soil, avoid construction inconvenience and improve cleaning effect , to ensure the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is further described in detail by specific embodiments:

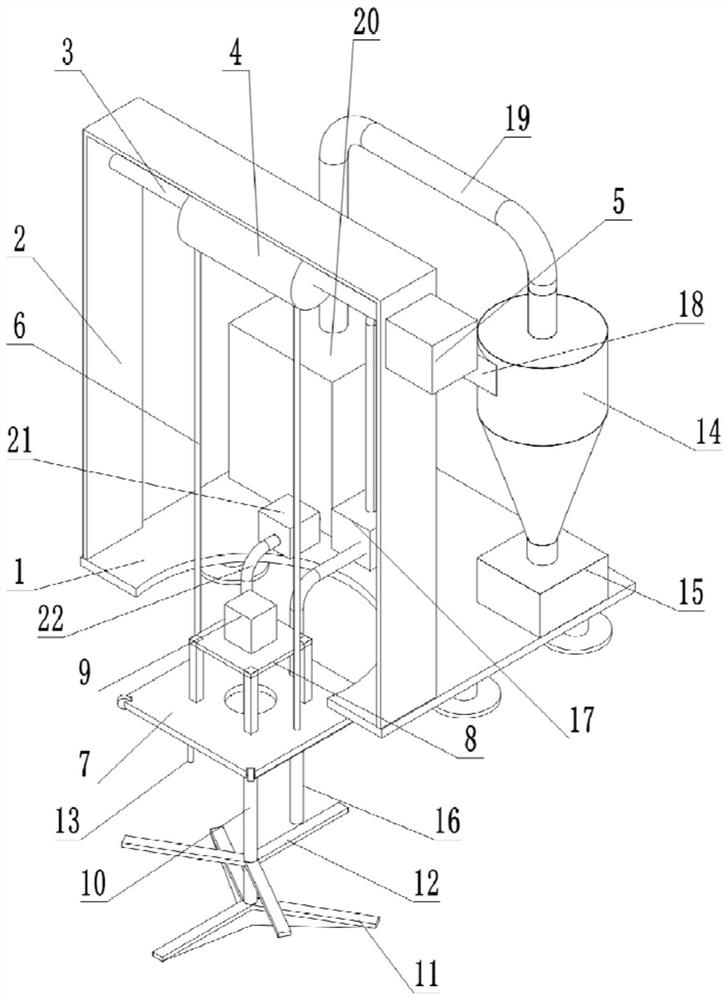

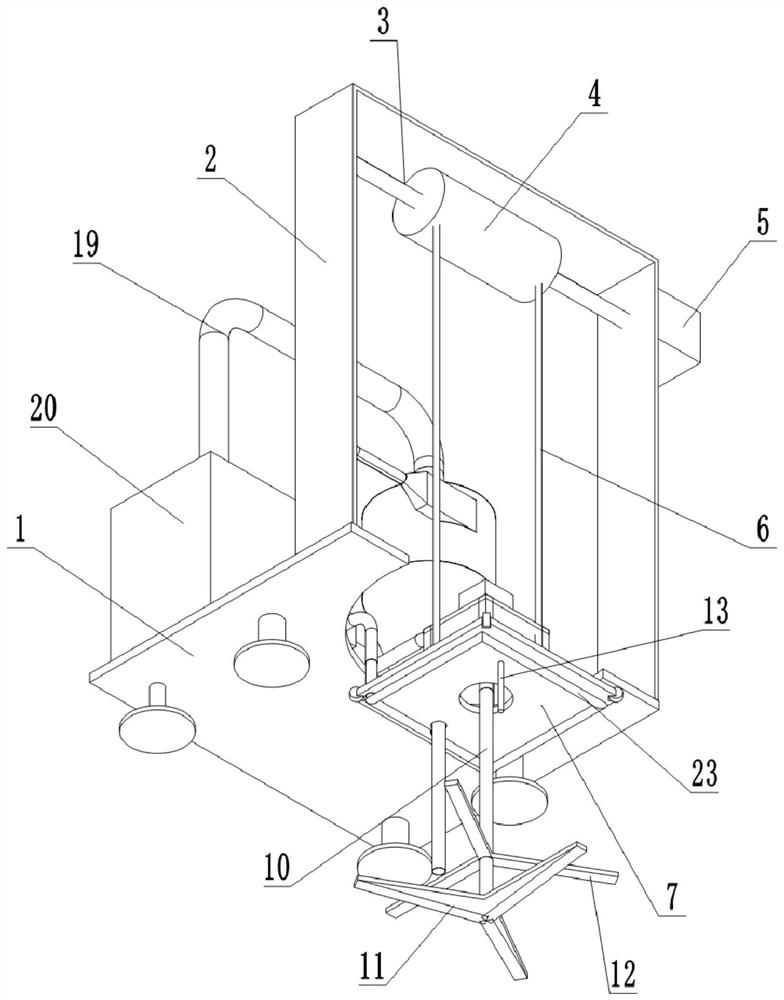

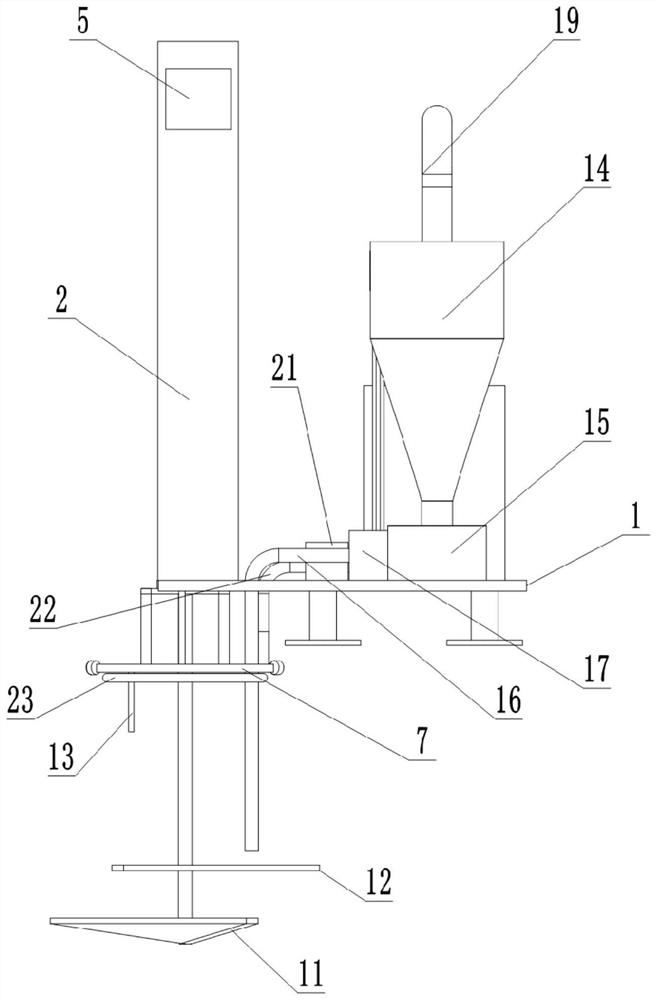

[0036] like Figure 1-Figure 8 As shown in the figure, a prefabricated pipe pile deep pile core soil cleaning device needs to be explained in advance that it should include a control system, such as a single chip microcomputer to control each component in the device according to a preset program, so that each component can be coordinated according to expected requirements. Operation, the structural part specifically includes the hoisting mechanism, the excavation mechanism and the suction mechanism.

[0037] The hoisting mechanism includes an installation bottom plate 1, which is provided with a gap matching the shape of the prefabricated pipe piles, the earth excavation mechanism is arranged directly above the gap, and at the same time, the bottom surface of the installation bottom plate 1 is also provided with fixed feet fixed to the ground. The mounting base 1 is provided with a mounting frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com