Automatic painting device for putty powder on circular groove wall of television background wall

A background wall and circular groove technology, which is applied in the direction of architecture and building structure, can solve the problems of putty powder staining on the body, difficult to paint in all directions, and slow speed, so as to avoid dead corners that are difficult to paint and avoid manual feeding , the effect of liberating artificial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

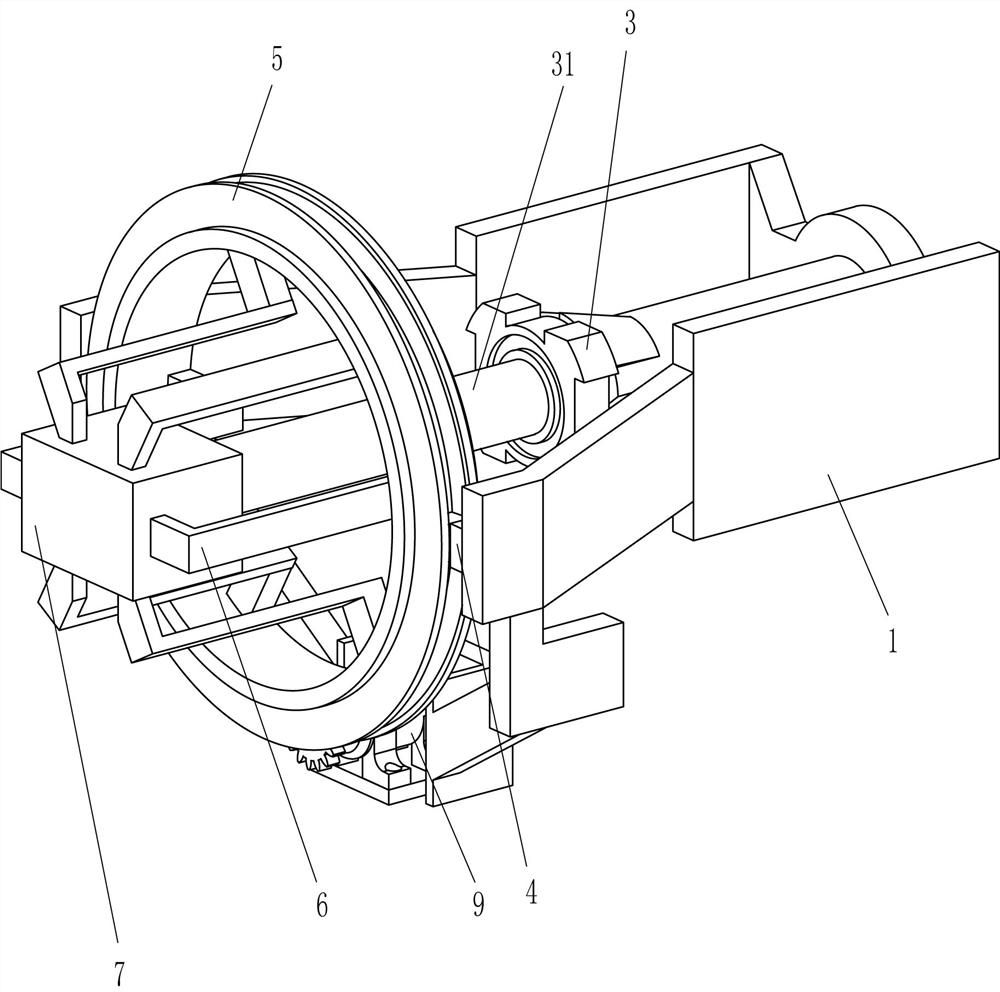

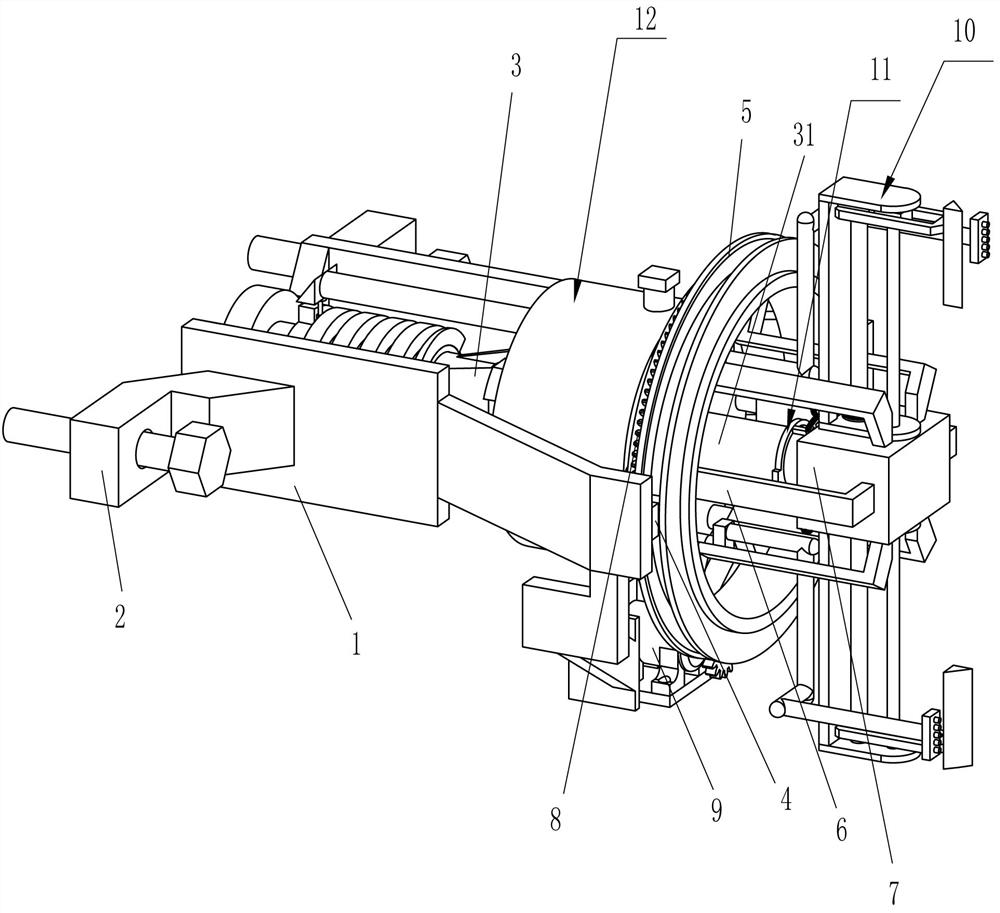

[0027] A kind of equipment for automatic brushing of putty powder on circular groove wall of TV background wall, such as Figure 1-5 As shown, it includes a fixed frame 1, a mounting frame 2, a fixed seat 3, a rotating rod 31, a slider 4, an annular slide rail 5, a connecting frame 6, a mounting block 7, a first gear transmission assembly 8, a driving motor 9, a brush Powder device 10 and displacement device 11, specifically:

[0028] Both sides front and back of fixed frame 1 right are connected with mounting frame 2, are connected with fixed seat 3 between the right side in fixed frame 1, and fixed seat 3 left side rotation type is connected with rotating rod 31, two front and rear left sides in fixed frame 1. Both sides are connected with sliders 4, and ring-shaped slide rails 5 are slidably connected between the sliders 4. The inner side of the ring-shaped slide rails 5 is connected with a connecting frame 6, and the connecting frame 6 is connected with a mounting block 7....

Embodiment 2

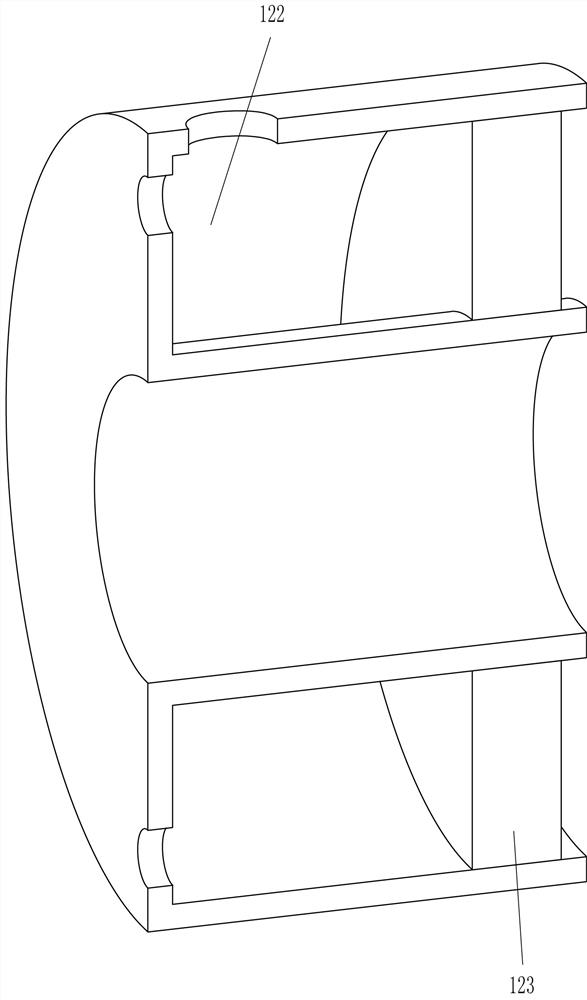

[0031] On the basis of Example 1, such as Figure 1-11 As shown, the powder brushing device 10 includes a support frame 101, a guide rail moving pair 102, a screw moving pair 103, a brush block 104, a rotating shaft 105, a second gear transmission assembly 106 and a transmission gear 107, specifically:

[0032] The upper and lower sides of the mounting block 7 are all connected with a support frame 101, and the support frame 101 is connected with a guide rail moving pair 102, and the upper and lower sides in the support frame 101 are connected with a screw moving pair 103 in a rotational manner, and the guide rail moving pair 102 and the wire The moving parts of the rod moving pair 103 are connected to each other and the left side is connected with a brush block 104, and the inside of the support frame 101 is connected with a rotating shaft 105 in a rotational manner, and a second shaft is connected between the rotating shaft 105 and the transmission shaft of the screw moving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com