Alloy steel for overhead conductor, preparation method of alloy steel and overhead conductor

An overhead wire and alloy steel technology, applied in the field of alloy steel, can solve the problems of low strength, increased tower weight, long-term operation, etc., achieve good corrosion resistance and fatigue resistance, improve strength and toughness, and prolong the service life effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

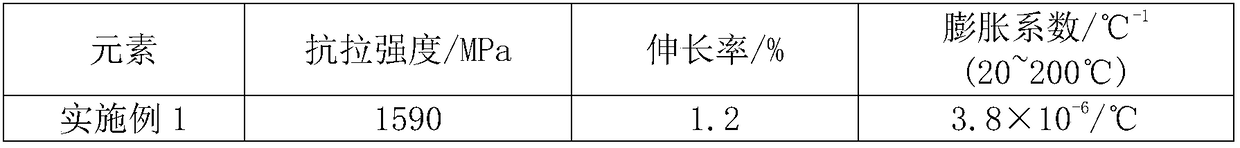

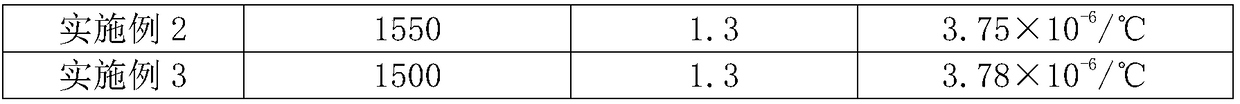

Embodiment 1

[0033] An alloy steel for overhead wires, comprising the following components by weight percentage: C: 0.1wt%, Si: 0.08wt%, Mn: 0.25wt%, P: 0.03wt%, S: 0.01wt%, Ni: 36wt% %, Cr: 0.7wt%, V: 1.3wt%, Be: 0.4wt%, the balance is Fe and unavoidable trace impurities.

[0034] The preparation and processing technology of above-mentioned alloy steel comprises the following steps:

[0035] (1) Raw material preparation: nickel plate dehydrogenation annealing, drying of all raw materials;

[0036] (2) Vacuum smelting: Add other alloying elements after melting iron to melt them all;

[0037] (3) Electroslag refining: After refining at 1450°C for 0.5h, pour into electroslag ingots;

[0038] (4) Preparation of steel billets: electroslag remelting is carried out, and steel billet ingots are obtained through furnace loading, arc ignition, slagging, smelting, feeding and cooling;

[0039] (5) High temperature forging: the initial forging temperature is 1150°C, and the final forging temperatu...

Embodiment 2

[0044] An alloy steel for overhead wires, comprising the following components by weight percentage: C: 0.2wt%, Si: 0.1wt%, Mn: 0.2wt%, P: 0.01wt%, S: 0.025wt%, Ni: 32wt% %, Cr: 0.5wt%, V: 1.0wt%, Be: 0.6wt%, the balance is Fe and unavoidable trace impurities.

[0045] The preparation and processing technology of above-mentioned alloy steel comprises the following steps:

[0046] (1) Raw material preparation: nickel plate dehydrogenation annealing, drying of all raw materials;

[0047] (2) Vacuum smelting: Add other alloying elements after melting iron to melt them all;

[0048] (3) Electroslag refining: Refining at 1450°C for 1 hour, pouring into electroslag ingots;

[0049] (4) Preparation of steel billets: electroslag remelting is carried out, and steel billet ingots are obtained through furnace loading, arc ignition, slagging, smelting, feeding and cooling;

[0050](5) High temperature forging: the initial forging temperature is 1200°C, and the final forging temperature ...

Embodiment 3

[0055] An alloy steel for overhead wires, comprising the following components by weight percentage: C: 0.25wt%, Si: 0.15wt%, Mn: 0.3wt%, P: 0.03wt%, S: 0.025wt%, Ni: 35wt% %, Cr: 0.6wt%, V: 0.8wt%, Be: 0.5wt%, the balance is Fe and unavoidable trace impurities.

[0056] The preparation and processing technology of above-mentioned alloy steel comprises the following steps:

[0057] (1) Raw material preparation: nickel plate dehydrogenation annealing, drying of all raw materials;

[0058] (2) Vacuum smelting: Add other alloying elements after melting iron to melt them all;

[0059] (3) Electroslag refining: Refining at 1450°C for 1.5h, casting into electroslag ingots;

[0060] (4) Preparation of steel billets: electroslag remelting is carried out, and steel billet ingots are obtained through furnace loading, arc ignition, slagging, smelting, feeding and cooling;

[0061] (5) High temperature forging: the initial forging temperature is 1170°C, and the final forging temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com