Reinforced high-temperature resistant optical fiber composite overhead insulating cable

An optical fiber composite, reinforced technology, applied in the direction of insulated cables, power cables for overhead applications, power cables including optical transmission components, etc. Strength, lack of tensile strength and other problems, to solve the effects of cable sagging, improved electrical conductivity, and increased tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

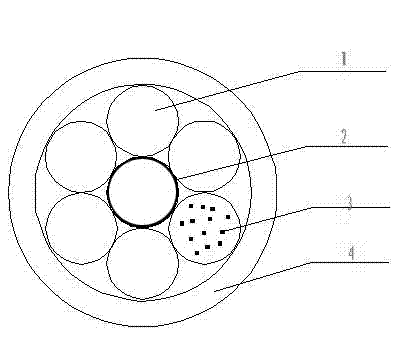

[0019] Example 1: Such as figure 1 As shown, a reinforced optical fiber composite high temperature resistant overhead insulated cable, from the inside to the outside, includes a solid carbon fiber composite reinforced core 2, five electrical soft aluminum monofilaments 1 and a stainless steel tube optical unit 3 in turn from the inside to the outside. The adjacent outer layer and the outer side of the formed single-tube layer-stranded type are the high temperature resistant insulating material layer 4.

[0020] The high-temperature resistant insulating material is silicon rubber or fluoroplastics; other materials can be used instead of electrical soft aluminum monofilaments as conductors.

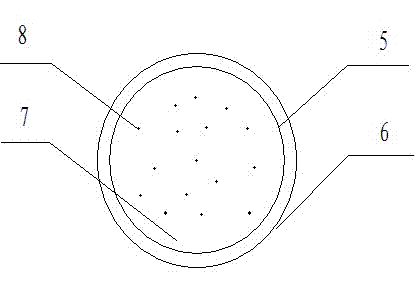

[0021] Such as image 3 As shown, the stainless steel tube light unit is composed of a number of optical fibers 8 placed in a stainless steel tube 5. The stainless steel tube 5 adopts a loose tube structure, the space of the stainless steel tube 5 is filled with a special filling paste 7 for lig...

Embodiment 2

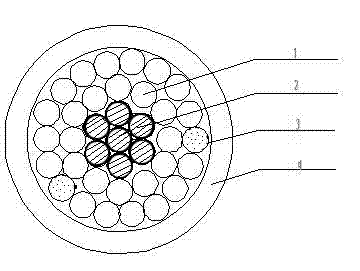

[0022] Example 2: Such as figure 2 As shown, a reinforced optical fiber composite high temperature resistant overhead insulated cable, from the inside to the outside, includes a composite reinforced core made of seven fine carbon fibers stranded in the center 2 and a number of 63% IACS electrical soft aluminum monofilaments 1 The adjacent outer layer of the multi-tube stranded type formed by twisting with two stainless steel tube light units 3 has a silicone rubber layer or a fluoroplastic layer 4 on the outside.

[0023] Manufacturing method: twist the fine carbon fiber composite core to make a composite reinforced core and place it in the center of the concentric stranded conductor, and then continue to twist the electrical soft aluminum monofilament on it in the same way, and the adjacent layer of electrical soft aluminum monofilament The twisting direction should be opposite, and then twist the prefabricated stainless steel tube light unit with the outermost electrical soft a...

Embodiment 3

[0025] Embodiment 3: A reinforced fiber optic composite high temperature resistant overhead insulated cable with a rated voltage of 10kV, and the shielding layer of semiconducting conductor should be extruded.

[0026] Other structures are the same as in embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com