Capacitive temperature sensing for electrical conductor

A conductor, temperature sensing technology, applied in capacitors, conductors, thermometers, etc. where the dielectric temperature changes, can solve problems such as problems in the power distribution system, and achieve the effect of reliable temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

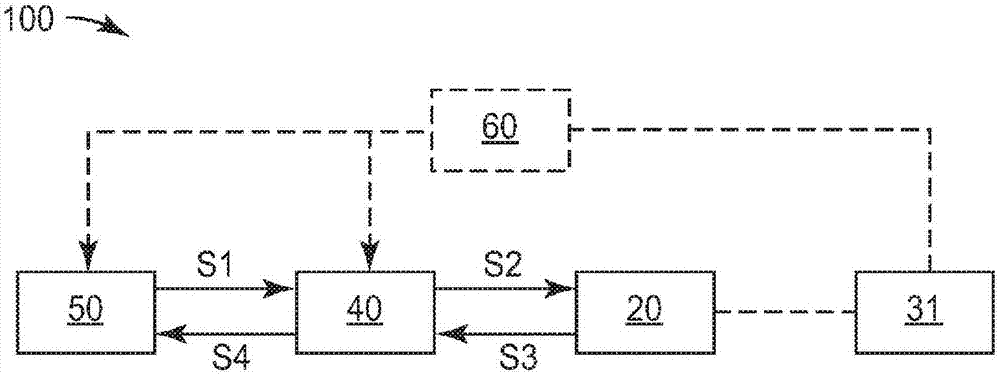

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

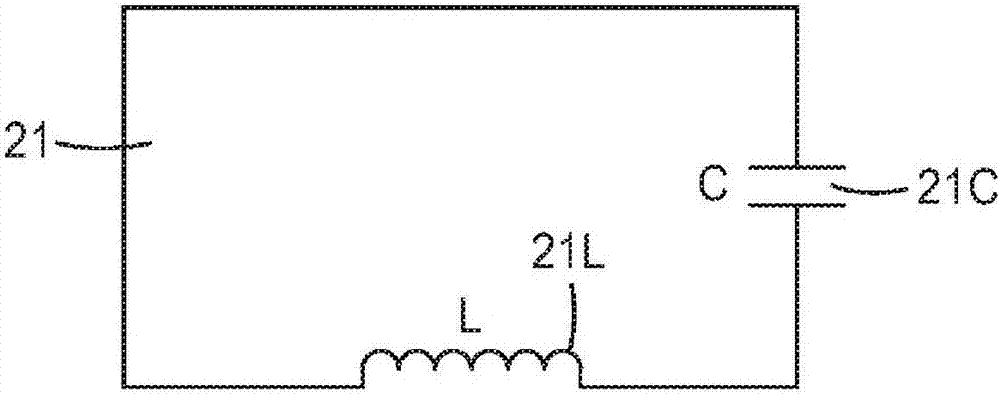

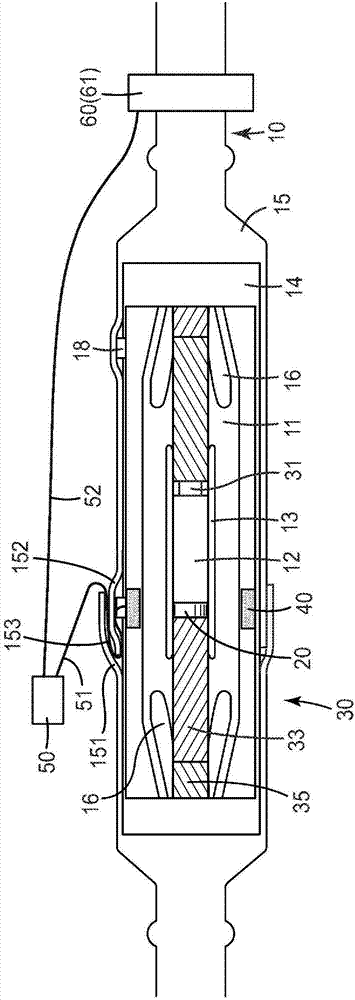

[0106] Example 1 - Temperature Sensitive Capacitor

[0107] Exemplary temperature sensitive capacitors were fabricated for sensing electrical conductors (e.g., figure 1 The temperature of the conductor 31). Temperature sensitive capacitors have as Figure 7 construction shown. The capacitor body is made of nylon-6 material. Electrodes are disposed on the outer surface of the capacitor body to form an interdigitated capacitor. The dielectric properties of temperature-sensitive capacitors were measured by using a dielectric spectrometer according to ASTM standard test methods (including ASTM D150 "Standard Test Method for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation").

[0108] Figure 8 is a graph showing the relationship between the temperature of the conductor 31 and the dielectric constant of the capacitor main body. The dielectric constants were measured at 133kHz, 94.9kHz and 67.8kHZ, respectively.

[0109] Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com