Multi-strand composite reinforcing core and preparation method thereof

A composite material and reinforcing core technology, used in cable/conductor manufacturing, conductors, insulated cables, etc., can solve the problems of reducing the safety factor of line operation and poor bending performance, and achieve excellent performance, good bending performance and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

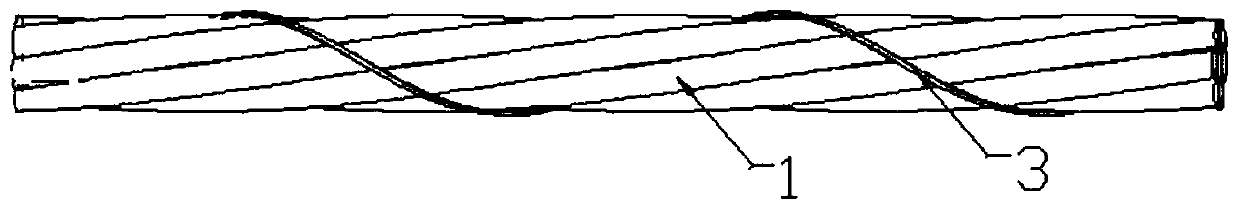

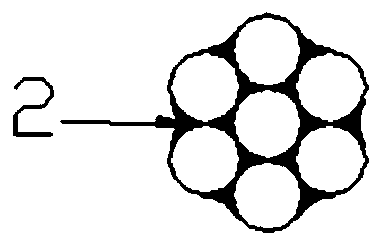

[0034] Such as figure 1 and figure 2 As shown, a multi-strand composite material reinforced core is formed by bonding multi-strand single-wire mandrels (1) through a matrix adhesive 2 (epoxy resin or silicone rubber resistance); the single-wire mandrel is one The number is 7 and the number of layers is 2.

[0035] The above-mentioned single-wire mandrel 1 has a diameter in the range of 0.5-6mm.

[0036] The cross-section of the above-mentioned single-wire mandrel 1 is circular.

[0037] The above-mentioned single-wire mandrel 1 is made of fibers and resin through a pultrusion process; the resin is epoxy resin; the fibers are carbon fibers and glass fibers.

Embodiment 2

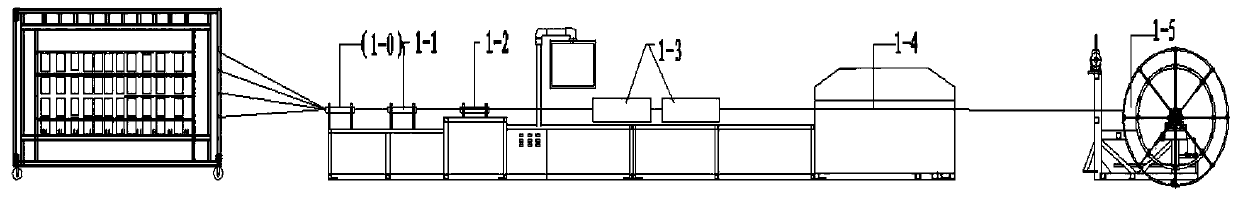

[0039] Such as image 3 Shown, the preparation method of a kind of multistrand composite reinforcement core provided by the present invention, it comprises the following steps:

[0040] Pack each single-wire mandrel 1 into a disc and place it in parallel, pass through the first dipping device 1-1 equipped with matrix adhesive 2 (epoxy resin), and enter the first The preforming device 1-2 is preliminarily fixed and formed, and then fully cured by the first post-curing device 1-3, and finally wound into a coil by the first winder 1-5. According to the actual use requirements, the first winding machine 1-0 can be placed in front of the first forming device 1-2 to wind the outer layer or not to wind the fiber, so as to prepare a multi-strand composite reinforcement core.

[0041] The multi-strand composite reinforcement core prepared above has better flexibility than the single-core structure reinforcement core in the prior art, and the smaller bending radius can better cope with...

Embodiment 3

[0044] Such as Figure 4 Shown, the preparation method of a kind of multistrand composite reinforcement core provided by the present invention, it comprises the following steps:

[0045] Pack each single-wire mandrel 1 into a disc, and install it on the cage stranding machine 2-1 with back-twisting function, add a second dipping device 2-2 at the outlet end of the cage stranding machine 2-1, and each single-wire mandrel 1 The surface is covered with matrix adhesive 2 (heat-resistant silicone rubber) after passing through the second dipping device 2-2 equipped with matrix adhesive 2, and enters the second molding device under the action of the second tractor 2-5 2-3. After the single-wire mandrels 1 of each layer are twisted and formed, they are fully cured by the second post-curing device 2-4, and finally wound into a coil by the second winder 2-6. According to actual use requirements, it is optional to place the second winding machine 2-0 in front of the second forming devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com