Large-cross-section carbon-fiber-composite-core semi-hard aluminum lead

A carbon fiber and large cross-section technology, applied in the direction of conductors, non-insulated conductors, cable/conductor manufacturing, etc., can solve the problems of being easily damaged by galloping phenomena, low tensile strength of wires, easy wear of wires, etc., to promote coordinated development, The effect of high carrying capacity and reducing the number of towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

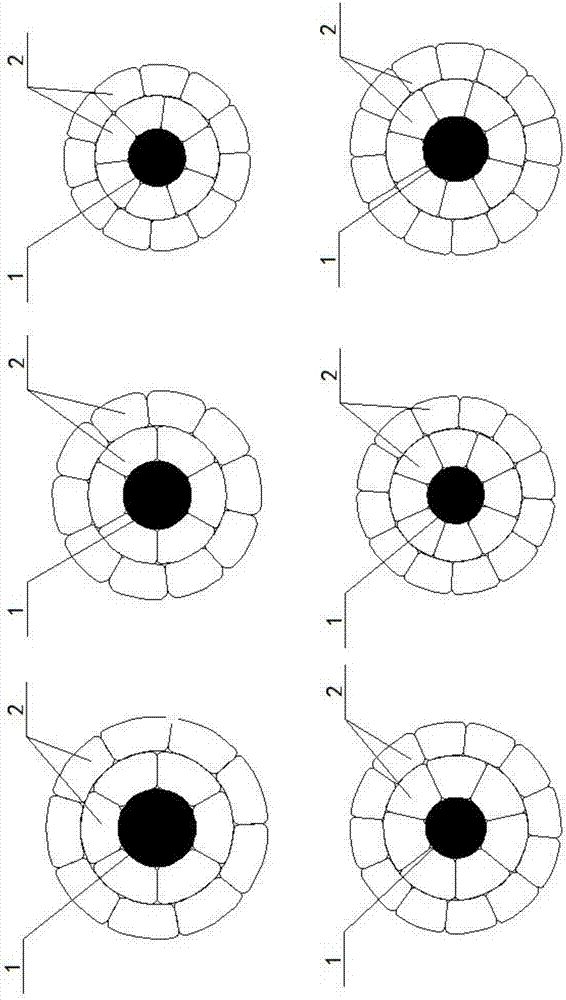

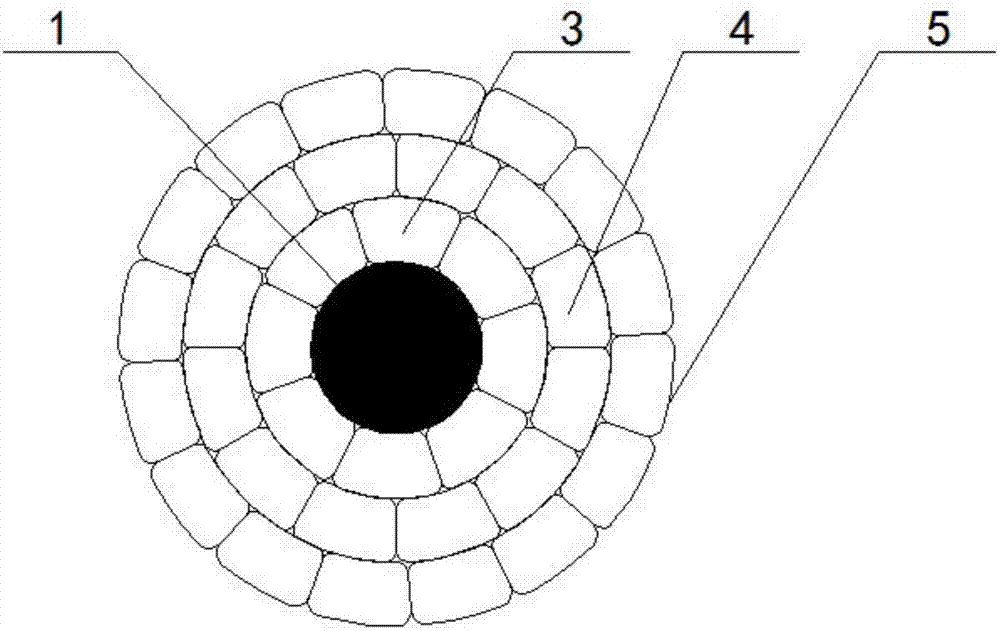

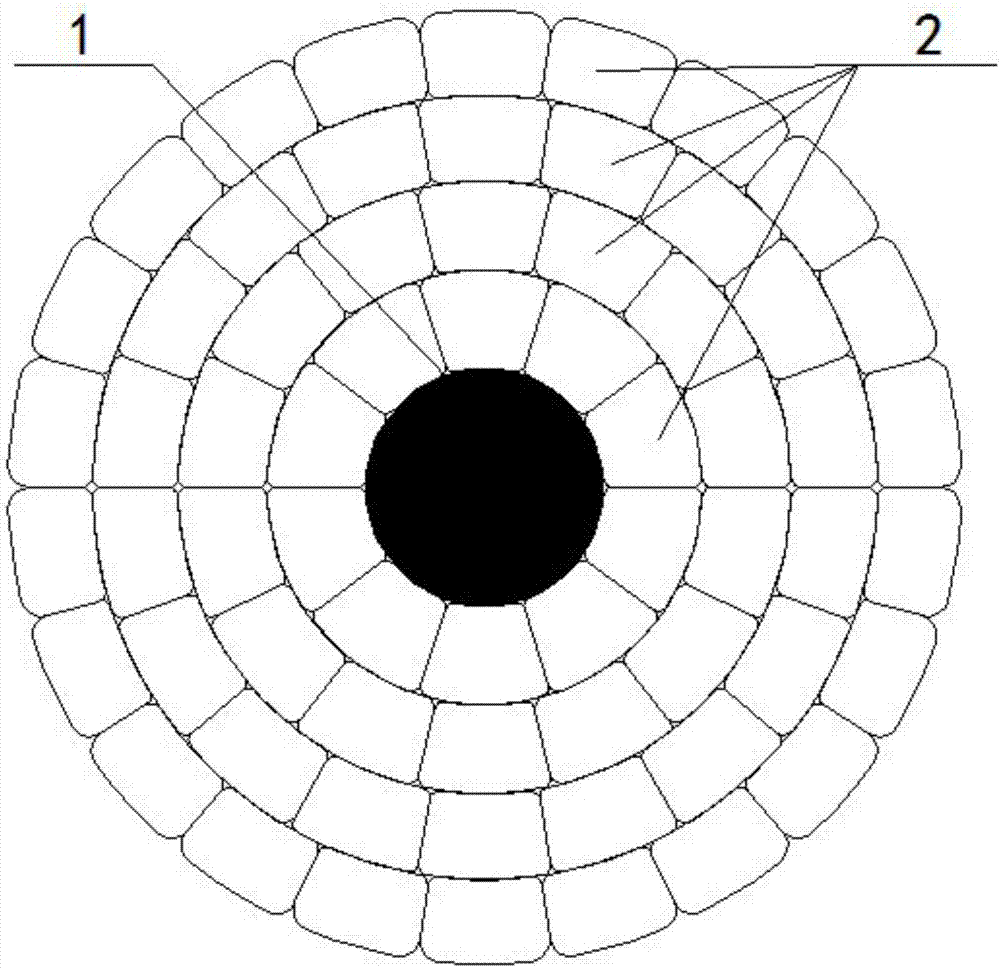

[0021] Embodiment 1, with reference to figure 1 , 2 3. A semi-duralumin conductor with a large cross-section carbon fiber composite core, comprising a carbon fiber composite mandrel 1 and some semi-duralumin wire layers 2 twisted outside the carbon fiber composite mandrel 1, the carbon fiber composite mandrel 1 comprising a composite material The inner core and the glass fiber composite material layer used for cladding the inner core of the composite material; its preparation method is: (1) the preparation of the carbon fiber composite mandrel, the inner core of the composite material is made of a single carbon fiber rope, and the glass fiber composite material layer is used Wrap the inner core of the composite material to make a carbon fiber composite mandrel; (2) Preparation of the semi-duralumin wire layer, straighten and clean the aluminum rod, remove the oxide layer, and prepare the semi-duralumin by drawing or extruding aluminum Monofilament, after the semi-duralumin mo...

Embodiment 2

[0022] Embodiment 2, in the large-section carbon fiber composite core semi-duralumin wire described in embodiment 1: the diameter of the carbon fiber composite core rod is 8.0-15.0mm.

Embodiment 3

[0023] Embodiment 3, in the large-section carbon fiber composite core semi-duralumin wire described in Embodiment 1 or 2: the semi-duralumin wire layer is an inner and outer double-layer structure, and the inner layer of semi-duralumin wire layer consists of 6-10 Composed of semi-duralumin wires, the outer layer of semi-duralumin wires consists of 8-14 semi-duralumin wires. In the semi-duralumin wire layer of the double-layer structure, the inner semi-duralumin wire can be set to 6 semi-duralumin wires, and the corresponding outer layer semi-duralumin wire can be set to 9 semi-duralumin wires; The hard aluminum wire is set to 6 semi-duralumin wires, and the corresponding outer layer semi-duralumin wire is set to 10 semi-duralumin wires; the inner layer semi-duralumin wire is set to 7 semi-duralumin wires, and the corresponding outer layer semi-dura The aluminum wires are set to 11 semi-duralumin wires; the inner layer semi-duralumin wires are set to 8 semi-duralumin wires, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com