Copper alloy wire, copper alloy stranded wire, coated electric wire, wire harness and manufacturing method of copper alloy wire

A technology of copper alloy wire and manufacturing method, which is applied in the direction of cable/conductor manufacturing, parts of conductive core, metal/alloy conductor, etc., and can solve problems such as characteristics that cannot have strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

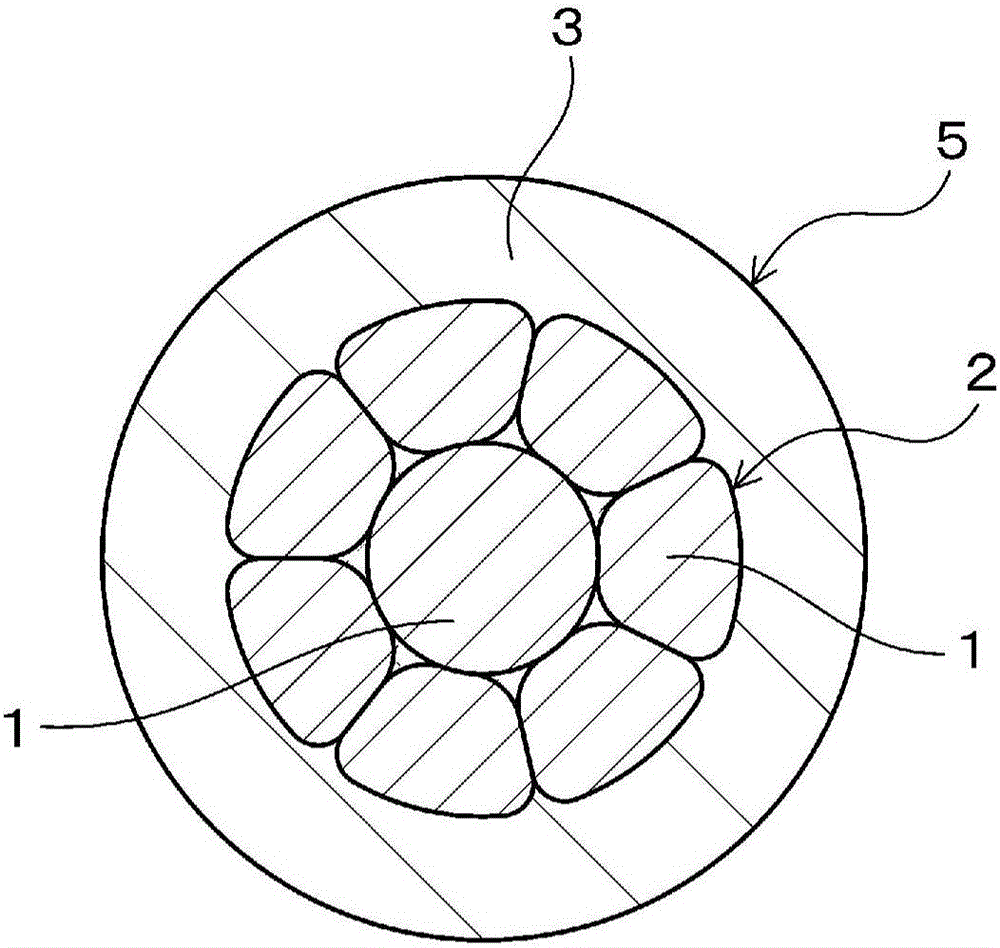

Embodiment 1

[0058] Examples related to the above-mentioned copper alloy wire and its manufacturing method will be described together with comparative examples. In this example, copper alloy wires having the chemical composition shown in Table 1 were produced and evaluated. Samples 1-1 to 1-17 contain Fe: 0.4 mass % to 2.5 mass %, Ti: 0.01 mass % to 1.0 mass %, Mg, Sn, Ag, Ni, In, Zn, Cr, Al, One or two or more elements selected from P: a total of 0.01% by mass to 2.0% by mass, and a copper alloy wire having a chemical composition of Cu and unavoidable impurities in the remainder. On the other hand, sample C101 as a comparative example is a copper alloy containing only Fe and a small amount of Ti as alloying elements, and sample C102 is a copper alloy containing only Mg as an alloying element.

[0059] In the production of copper alloy wire, first, electrolytic copper with a purity of 99.99% or more and a master alloy containing various additive elements are put into a high-purity carbona...

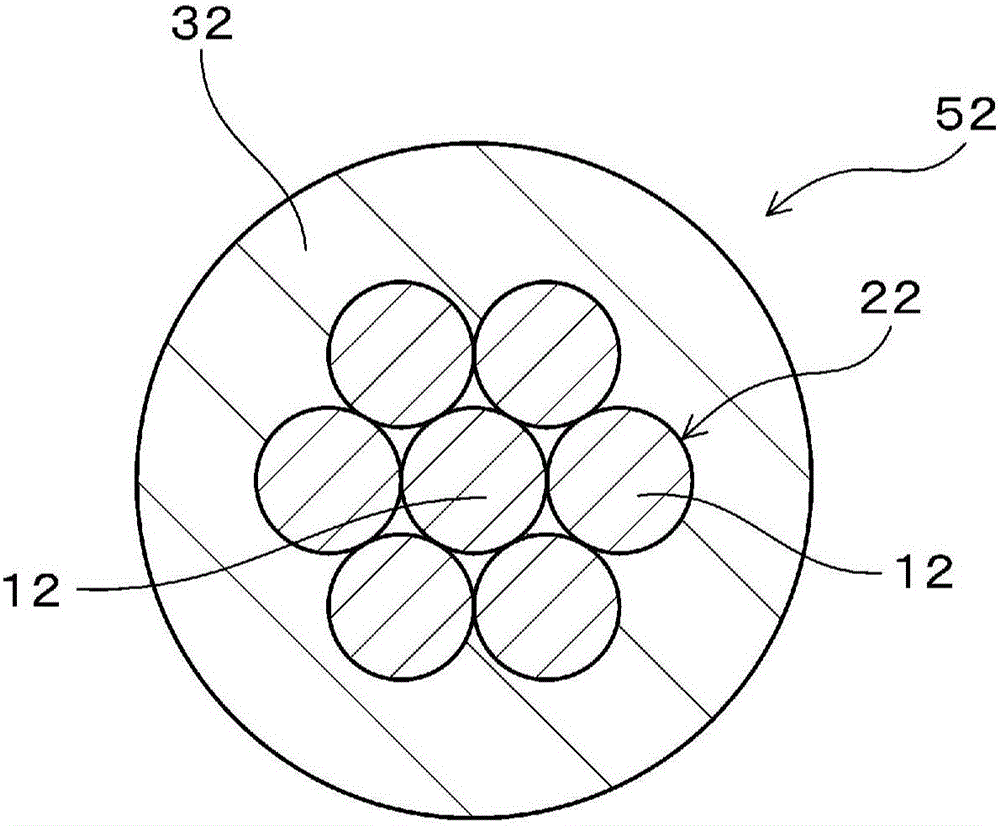

Embodiment 2

[0066] In this example, after producing copper alloy wires having the chemical composition shown in Table 2, a twisted wire obtained by twisting seven copper alloy wires was produced and evaluated. Samples 2-1 to 2-15 contain Fe: 0.4 mass % to 2.5 mass %, Ti: 0.01 mass % to 1.0 mass %, Mg, Sn, Ag, Ni, In, Zn, Cr, Al, One or two or more elements selected from P: a total of 0.01% by mass or more and 2.0% by mass or less, and a stranded wire having a chemical composition of Cu and unavoidable impurities in the remainder. On the other hand, sample C201 as a comparative example is a copper alloy containing only Fe and a small amount of Ti as alloying elements, and sample C202 is a copper alloy containing only Mg as an alloying element.

[0067] In the production of copper alloy wire, first, electrolytic copper with a purity of 99.99% or more and a master alloy containing various additive elements are put into a high-purity carbonaceous crucible and vacuum-dissolved in a continuous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com