Polycarbonate resin composition, molded body, and carrier tape

A technology of polycarbonate resin and composition, applied in the field of molded body, carrier tape, and polycarbonate resin composition, can solve the problems of thermal deterioration of resin, decrease of conductivity of molded body, etc. Decreased conductivity, effect of excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] (Preparation method of resin composition)

[0081] The polycarbonate resin composition of the present embodiment can be obtained by mixing the constituent components. The method for mixing the constituent components of the polycarbonate resin composition of the present embodiment is not particularly limited, and for example, after mixing using an arbitrary mixer (drum mixer, ribbon mixer, high-speed mixer, etc.), A method of melt-kneading using an extruder or the like.

[0082]

[0083] The molded body (molded article) of the present embodiment contains the polycarbonate resin composition of the present embodiment. The molded body of the present embodiment may be in the form of a film or in the form of a flat plate. As a molded object of this embodiment, a film, an adhesive tape, a sheet, etc. are mentioned. As the molded body of the present embodiment, for example, a container for accommodating electronic components (for example, a container for transportation or ...

Embodiment

[0090] The present invention will be described below by way of examples, but the present invention is not limited by these examples.

[0091]

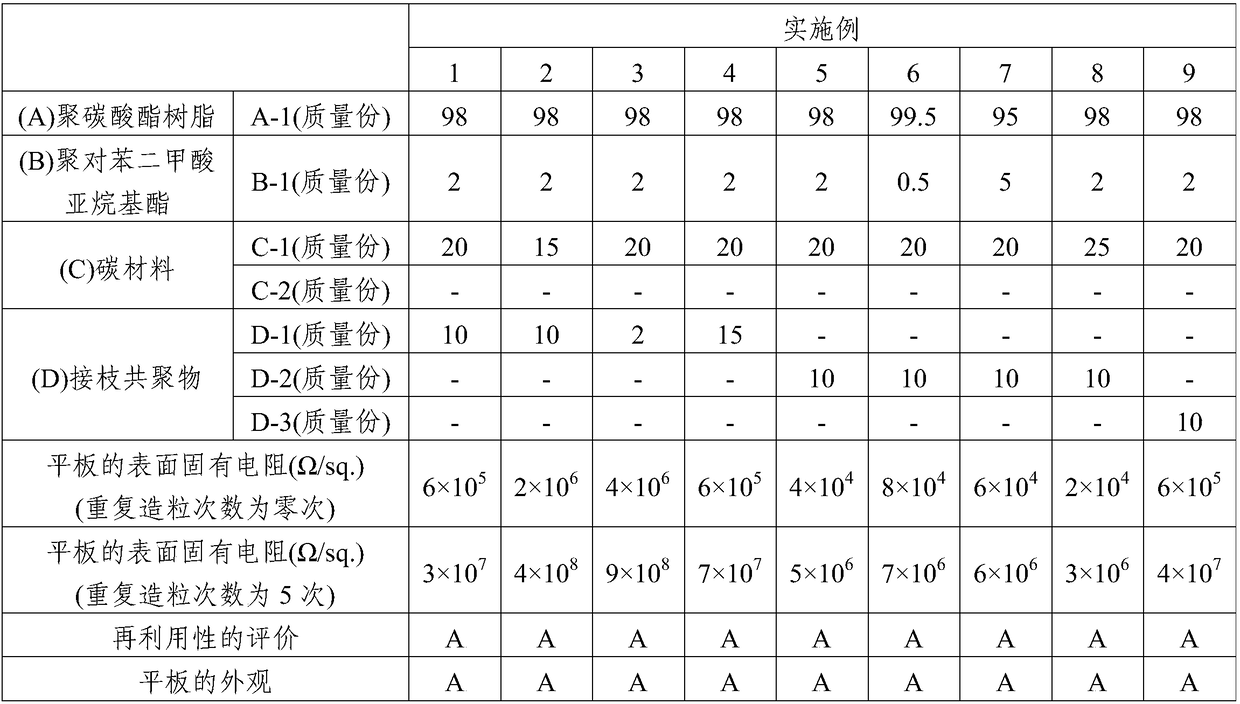

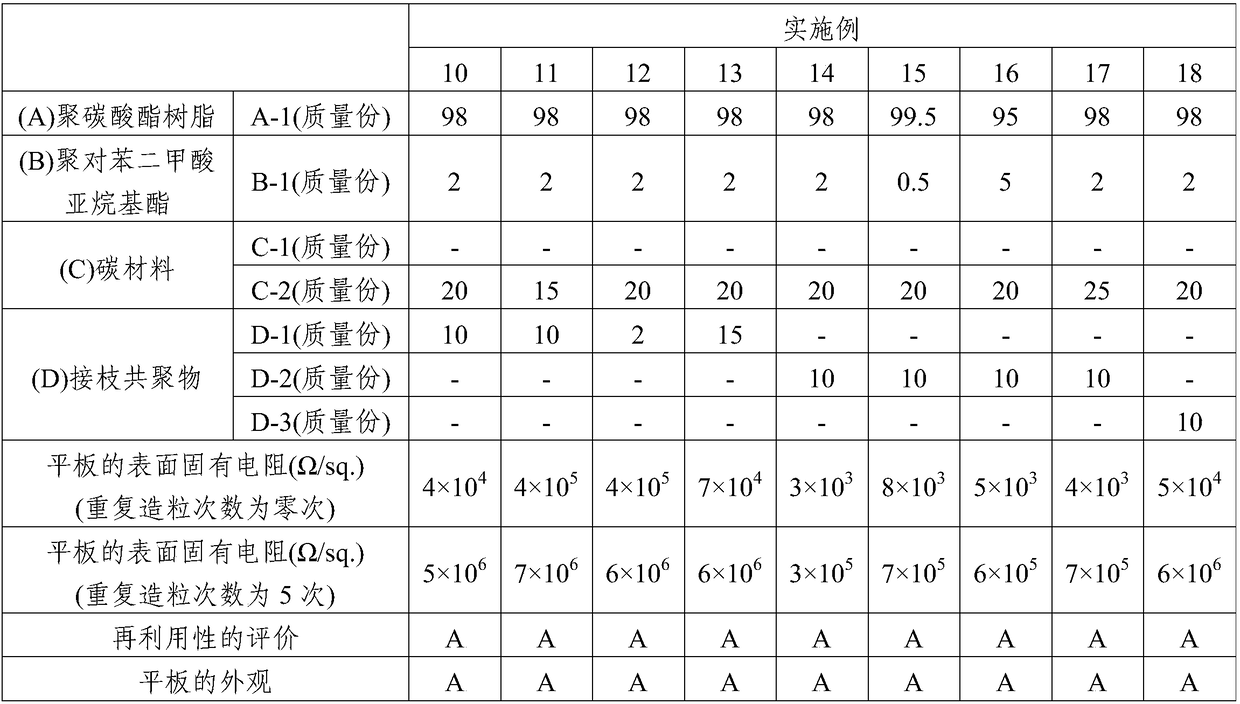

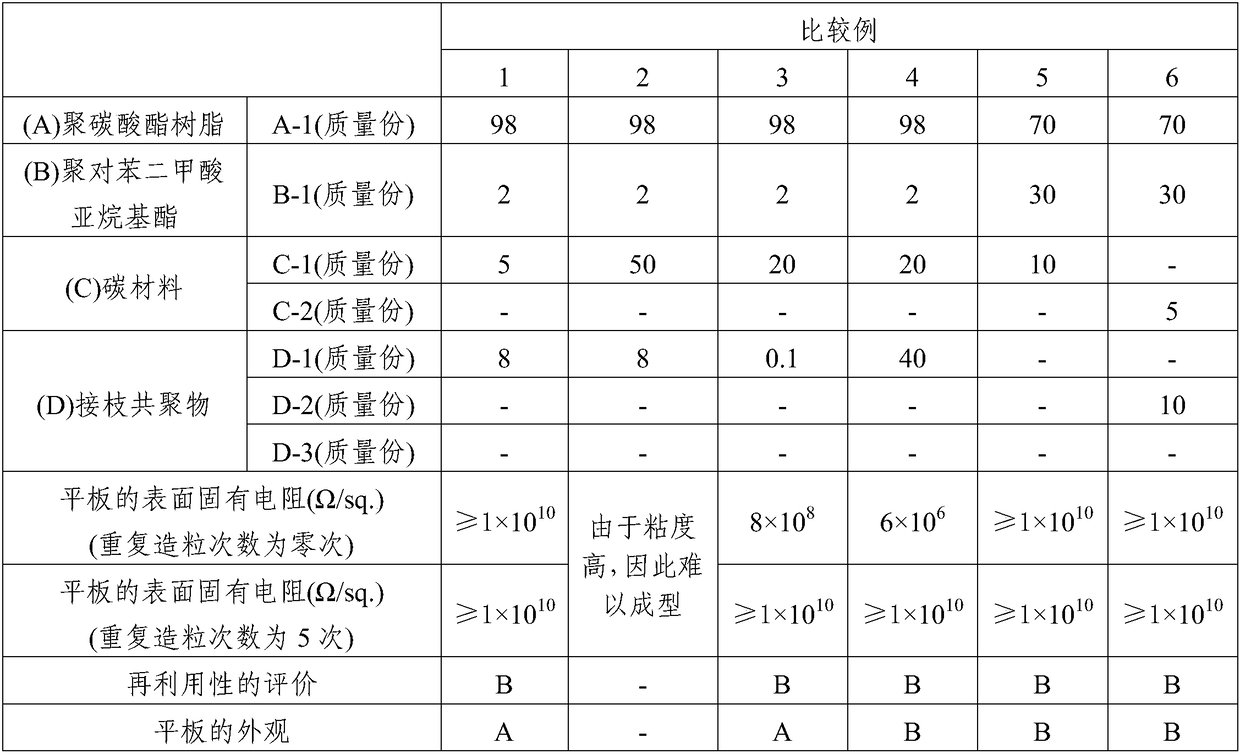

[0092] The additive components of the content shown in Tables 1-3 were prepared. Then, using a twin-screw extruder (manufactured by KOBESTEEL, LTD., KTX-37) having a diameter of 37 mm, the additive components were melt-kneaded at a barrel temperature of 280° C. to obtain various pellets.

[0093] The details of the additive components used are as follows.

[0094] [polycarbonate resin]

[0095] A-1: Polycarbonate resin synthesized from bisphenol A and phosgene, manufactured by Sumika Polycarbonate Ltd., CALIBRE 200-13 (viscosity average molecular weight: 21000)

[0096] [Polyalkylene terephthalate resin]

[0097] B-1: Polybutylene terephthalate resin, manufactured by Polyplastics Co., Ltd., Juranex 600FP (intrinsic viscosity: 1.0)

[0098] [carbon material]

[0099] C-1: Furnace carbon black, manufactured by Cabot Corporation, V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com