Soft copper alloy and soft copper alloy wire or board

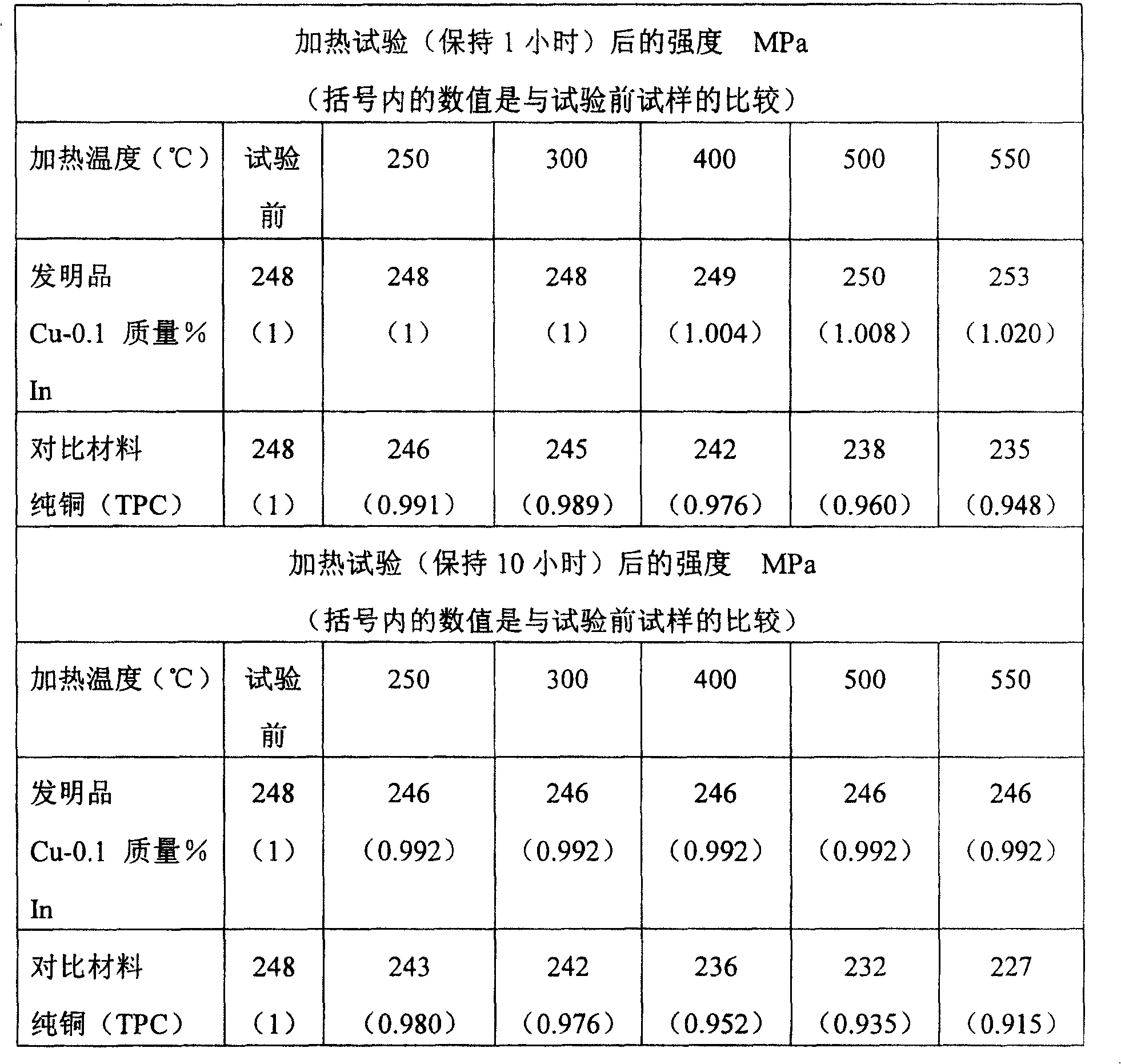

A technology of copper alloy wire and copper alloy, which is applied in the field of soft copper alloy and soft copper alloy wire or plate, which can solve the problems of decreased electrical conductivity or cold workability, decreased electric rate, and broken wires, and achieves excellent bending resistance and heat resistance, and the effect of suppressing the decrease in electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, suitable examples of the copper alloy according to the present invention will be described.

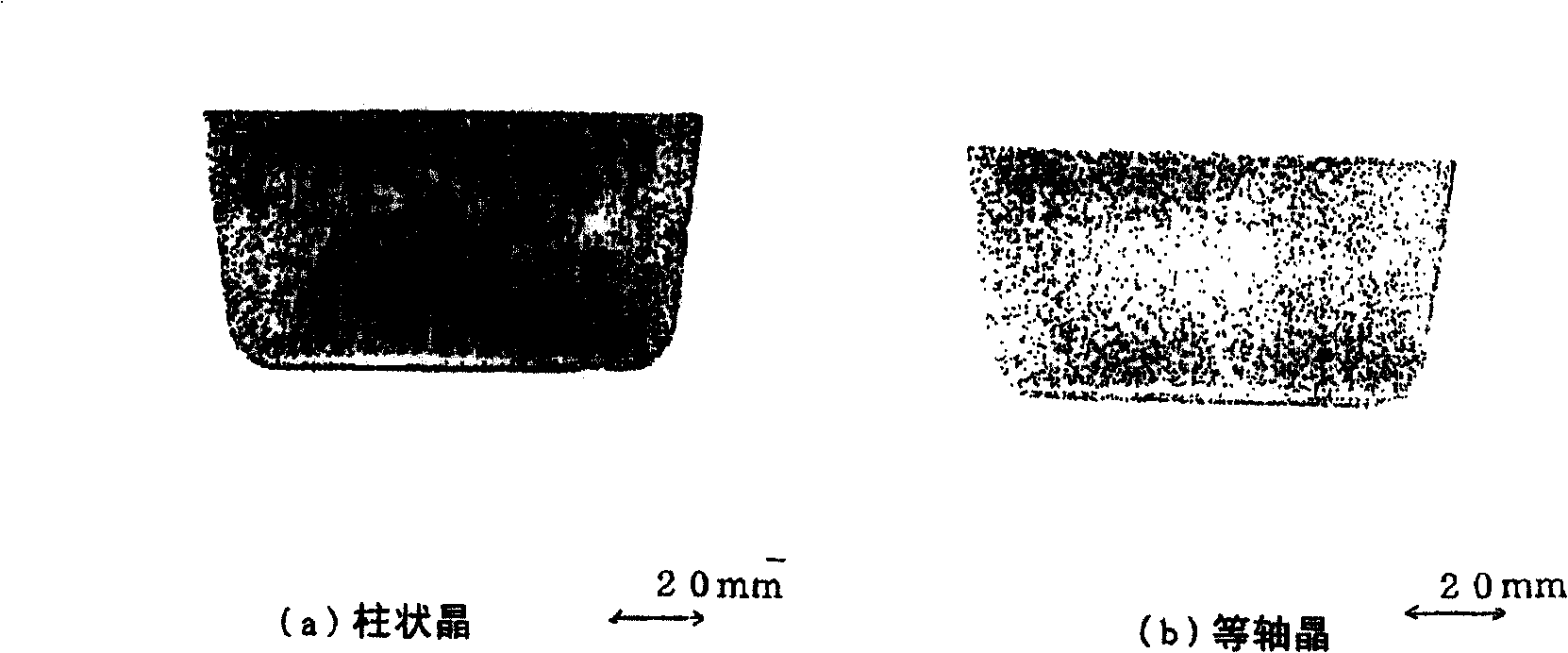

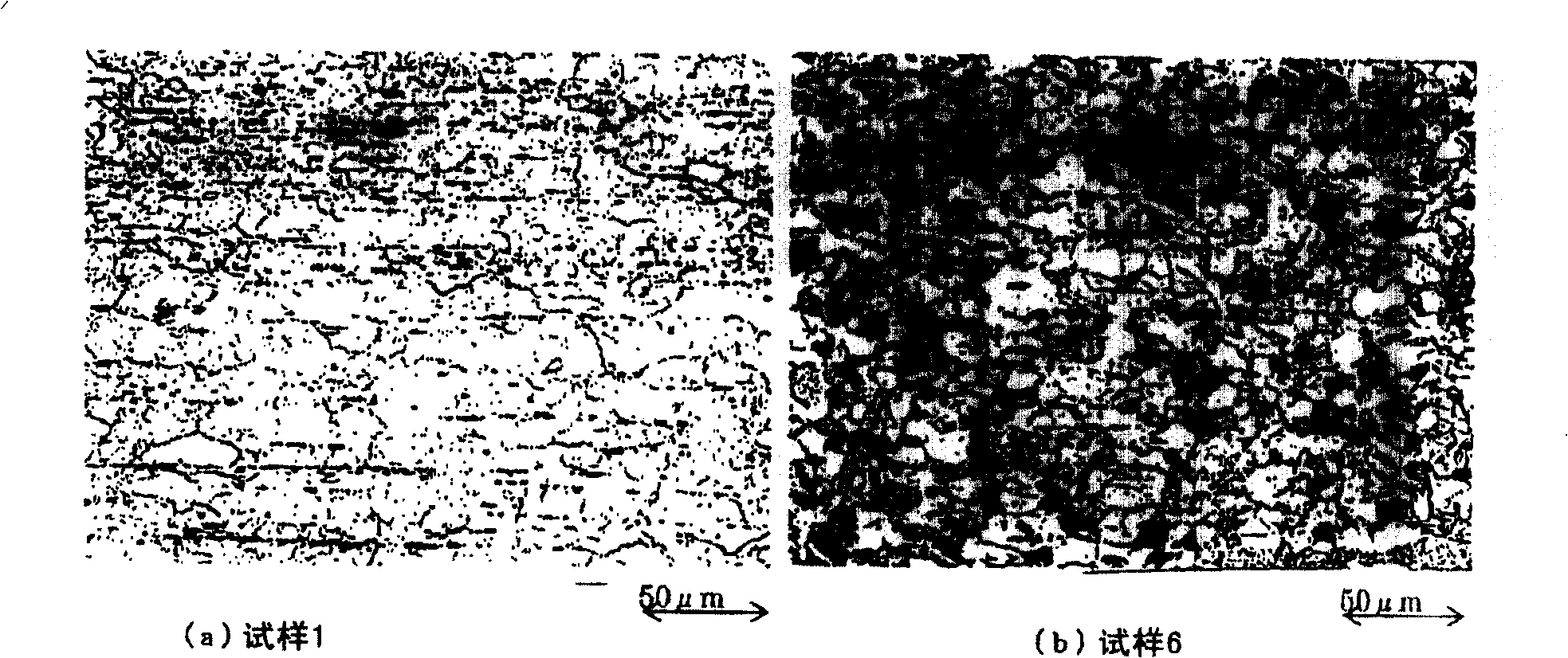

[0026] [Quality of ingot and rough drawing]

[0027] The quality of the rough drawing obtained by continuous casting is determined by the microstructure of the copper alloy in the ingot before processing. Therefore, in order to manufacture an industrially applicable copper-indium-based alloy wire with stable quality, it is necessary to control the structure at the ingot stage.

[0028] Table 1 compares the microstructure of the ingots produced under several different conditions and the quality of the rough wire drawn from these ingots. Here, the casting speed was 30 tons / hour, and casting cooling was performed with a copper casting ring. Also, continuous casting and rolling is performed by the SCR system.

[0029] In addition, for this embodiment, each material is continuously cast and rolled by the SCR system, but the present invention is not limited to this, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com