Trapped vortex type micro-turbine engine combustion chamber

A gas turbine and engine technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of insufficient combustion of fuel, short combustion residence time, increased heat transfer loss, etc., to reduce wall temperature and temperature gradient , Improve combustion stability and combustion efficiency, and increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

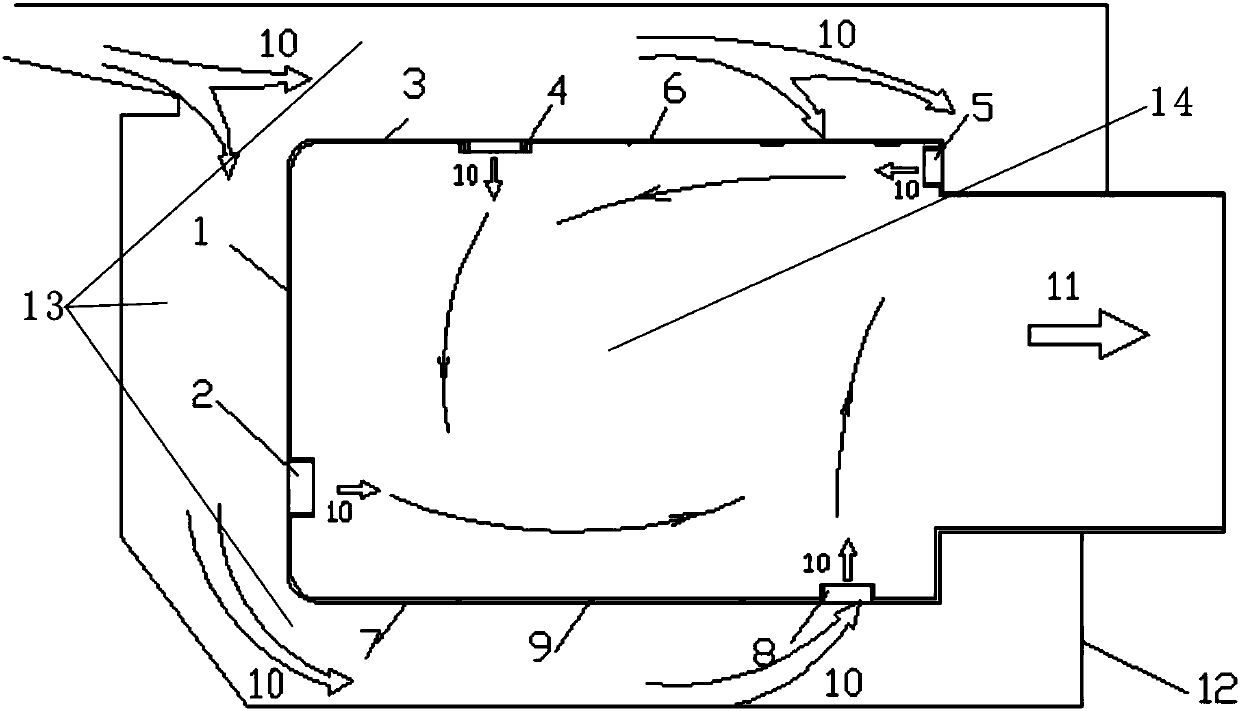

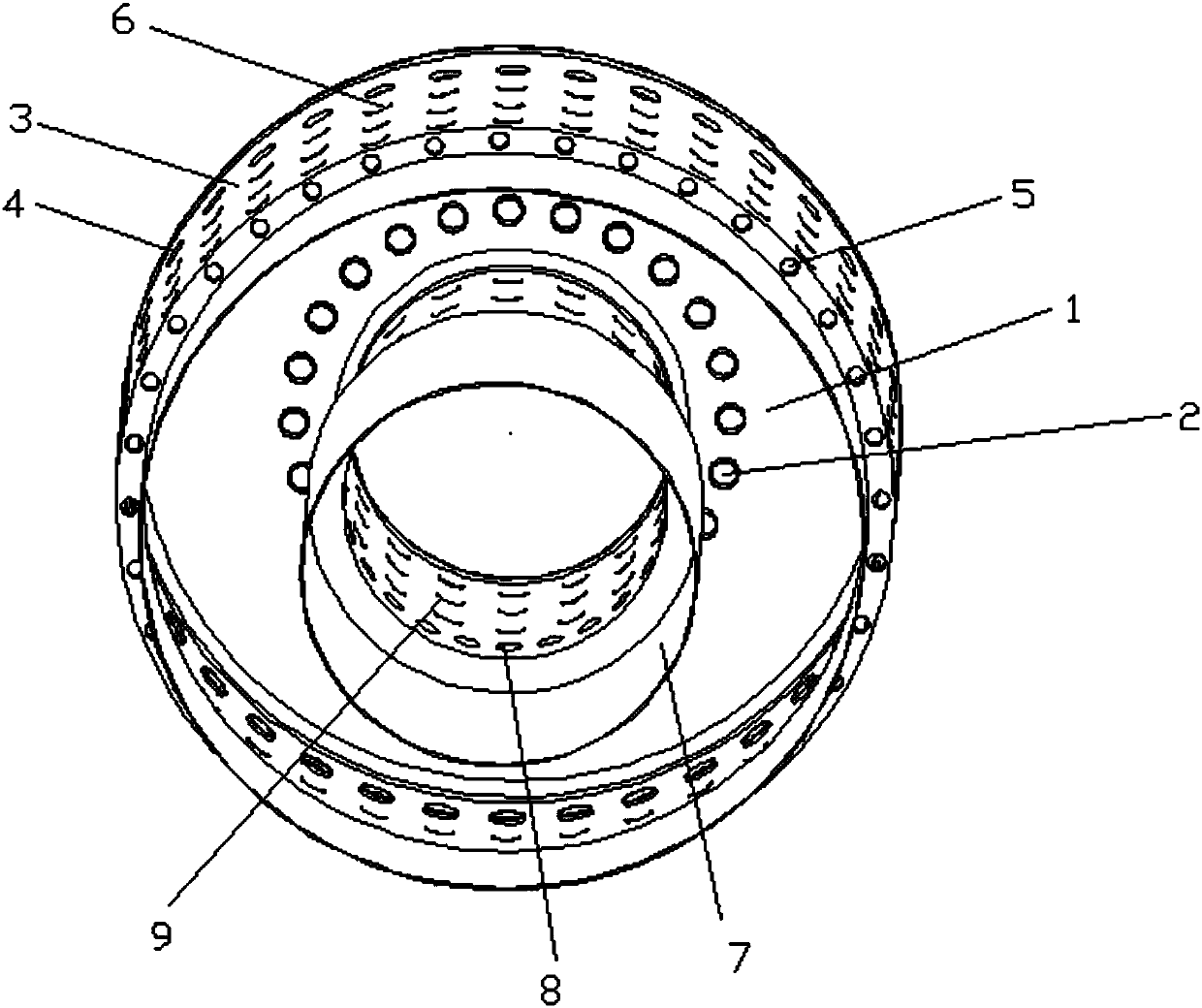

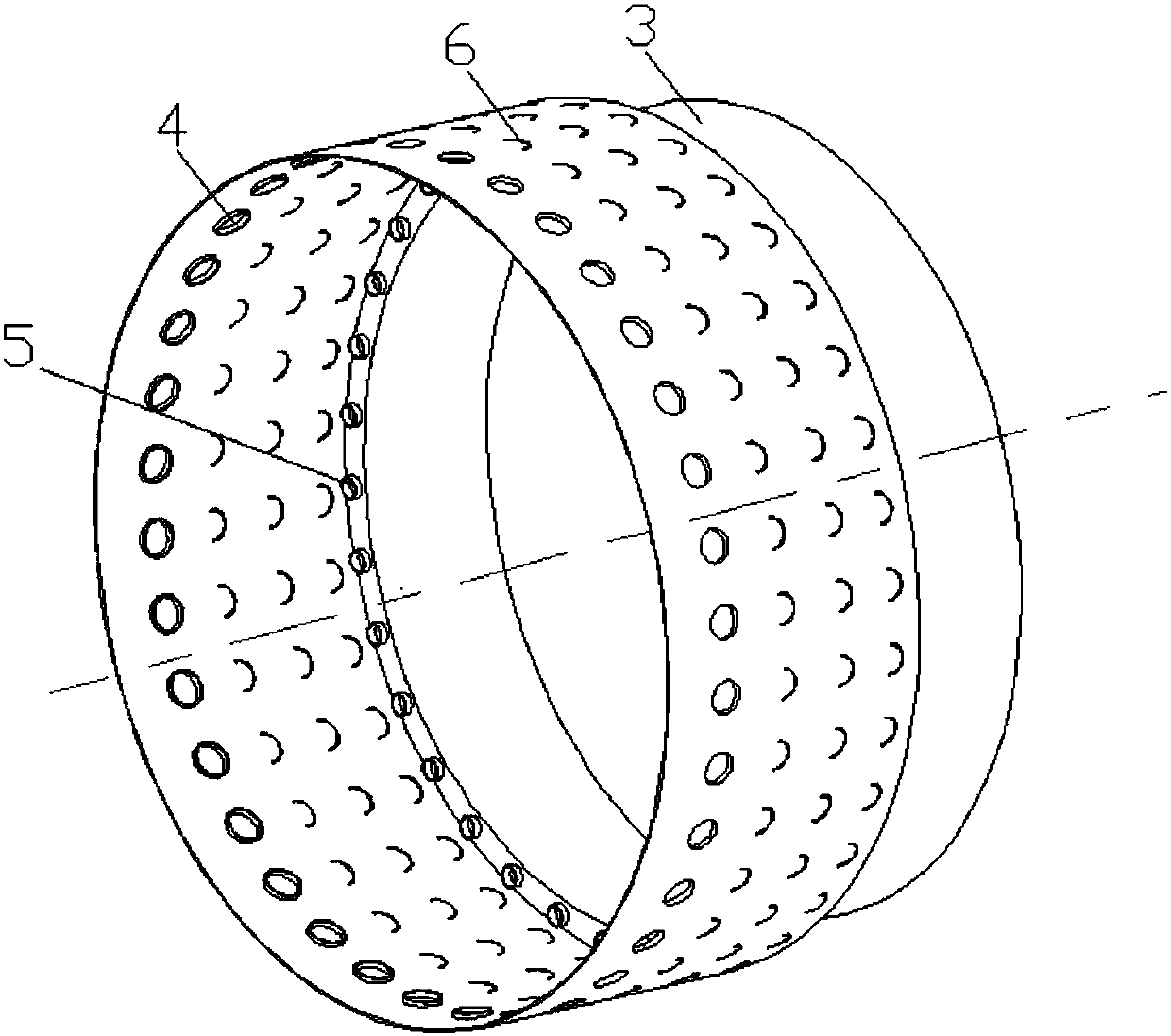

[0027] like Figure 1 to Figure 5 As shown, a combustion chamber of a vortex type micro gas turbine engine comprises a flame tube and a casing 12, and the flame tube includes a flame tube outer wall 3, a flame tube front wall 1 and a flame tube inner wall 7; the flame tube is close to the flame tube front wall 1 One end is the main combustion area at the head of the flame tube, the main combustion area at the head of the flame tube adopts a sudden expansion structure, and the main combustion area at the head of the flame tube is a vortex structure. The flame tube outer wall 3 is sealed and fixedly connected with the flame tube front wall 1, the flame tube inner wall 7 is located inside the flame tube outer wall 3, and the flame tube inner wall 7 is sealed and fixedly connected with the flame tube front wall 1. Both the outer wall 3 of the flame tube and the inner wall 7 of the flame tube of the present invention adopt a variable section design. The outer wall 3 of the flame t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com