Bio-based nylon composite PLA material and preparation method thereof

A technology of bio-based nylon and PA610, which is applied in the field of bio-based nylon composite PLA materials and its preparation, can solve the problems of slow crystallization speed of polylactic acid resin, large shrinkage rate of molded products, and restrictions on the application of engineering plastics, etc., and achieve good biodegradability properties, good heat resistance, improved discoloration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

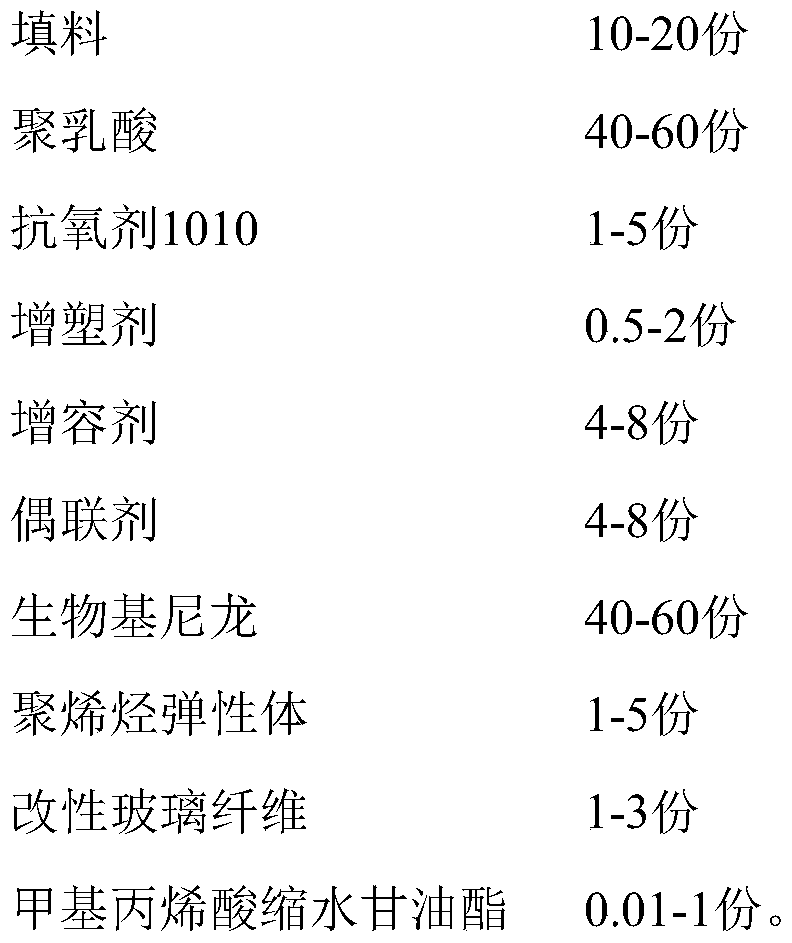

[0033] A kind of bio-based nylon composite PLA material, comprises the raw material of following weight portion:

[0034]

[0035] Each part of the bio-based nylon is a mixture of PA56 and PA610 in a weight ratio of 0.8:1.0.

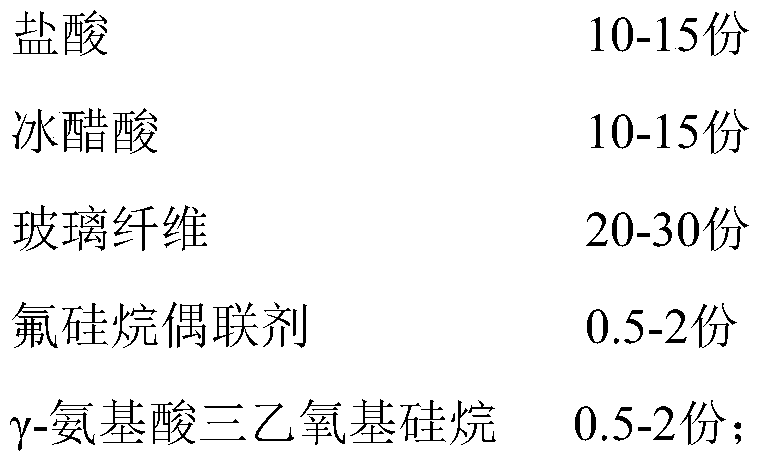

[0036] Each part of the modified glass fiber includes the following raw materials in parts by weight:

[0037]

[0038] The concentration of the hydrochloric acid is 0.5mol / L.

[0039] Described modified glass fiber is made by following method:

[0040] 1) Put the glass fiber infiltrated by the acid reagent into the drying device, heat to 300°C and bake for 60 minutes, cool to room temperature, and set aside;

[0041] 2) Soak the glass fiber cooled in step 1) in hydrochloric acid for 30 minutes, then rinse it with deionized water, dry it, and set aside;

[0042] 3) Add the glass fiber treated in step 2) into the mixture composed of fluorosilane coupling agent and γ-amino acid triethoxysilane and stir for 20 minutes, then add glacial acetic acid,...

Embodiment 2

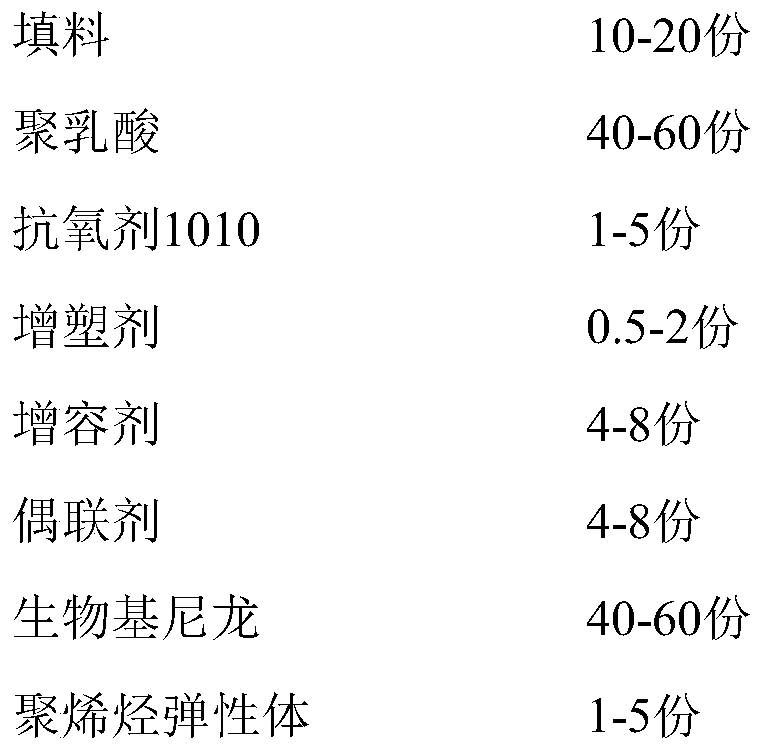

[0052] A kind of bio-based nylon composite PLA material, comprises the raw material of following weight portion:

[0053]

[0054]

[0055] Each part of the bio-based nylon is a mixture of PA56 and PPA in a weight ratio of 0.8:1.0.

[0056] Each part of the modified glass fiber includes the following raw materials in parts by weight:

[0057]

[0058] The concentration of the hydrochloric acid is 0.75mol / L.

[0059] Described modified glass fiber is made by following method:

[0060] 1) Put the glass fiber infiltrated by the acid reagent into the drying device, heat to 325°C and bake for 67 minutes, cool to room temperature, and set aside;

[0061] 2) Soak the glass fiber cooled in step 1) in hydrochloric acid for 37 minutes, then rinse it with deionized water, dry it, and set aside;

[0062] 3) Add the glass fiber treated in step 2) into the mixed solution composed of fluorosilane coupling agent and γ-amino acid triethoxysilane and stir for 22 minutes, then add gl...

Embodiment 3

[0072] A kind of bio-based nylon composite PLA material, comprises the raw material of following weight portion:

[0073]

[0074] Each part of the bio-based nylon is a mixture of PA56 and PA1012 in a weight ratio of 0.8:1.0.

[0075] Each part of the modified glass fiber includes the following raw materials in parts by weight:

[0076]

[0077] The concentration of the hydrochloric acid is 1mol / L.

[0078] Described modified glass fiber is made by following method:

[0079]1) Put the glass fiber infiltrated by the acid reagent into the drying device, heat to 350°C and bake for 75 minutes, cool to room temperature, and set aside;

[0080] 2) Soak the glass fiber cooled in step 1) in hydrochloric acid for 45 minutes, then rinse it with deionized water, dry it, and set aside;

[0081] 3) Add the glass fiber treated in step 2) into the mixture composed of fluorosilane coupling agent and γ-amino acid triethoxysilane and stir for 23 minutes, then add glacial acetic acid, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com