Single-component thermoplastic polyurethane adhesive and preparation method thereof

A thermoplastic polyurethane and adhesive technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of easy thermal oxidative degradation, unfavorable mass production, poor oxidation resistance, etc. Accelerate the curing speed, improve the bonding effect, and the effect of good extraction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

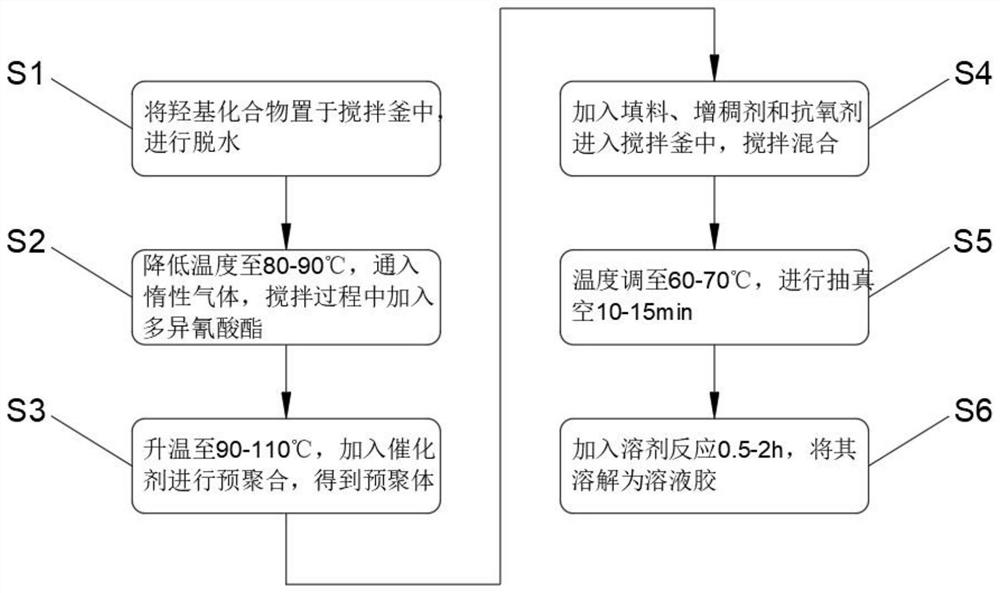

[0029] Embodiment 1 A kind of one-component thermoplastic polyurethane adhesive and preparation method thereof, comprising:

[0030] 1. Preparation of polyurethane prepolymer

[0031] Put 150 parts of hydroxyl compound in a stirred tank, the temperature of the stirred tank is 100-120°C, the pressure is 10-20mbar, the speed is 180-230rpm, dehydrate, lower the temperature to 80-90°C, pass in an inert gas, and stir During the process, add 30 parts of polyisocyanate, raise the temperature to 90-110°C, add 0.2 parts of catalyst for prepolymerization, and obtain a prepolymer;

[0032] The polyhydroxy compound is polybutylene succinate, the molecular weight is 1000-3000g / Pmol, and the polyisocyanate component is diphenylmethane diisocyanate;

[0033] The catalyst is one or two mixtures of bismorpholino diethyl ether and dibutyltin dilaurate. Since the one-component polyurethane prepolymer requires long-term storage stability, bismorpholine diethyl ether and dibutyltin dilaurate Dib...

Embodiment 2

[0039] Embodiment 2 A kind of one-component thermoplastic polyurethane adhesive and preparation method thereof, comprising:

[0040] 1. Preparation of polyurethane prepolymer

[0041] Put 165 parts of hydroxyl compound in a stirred tank, the temperature of the stirred tank is 100-120°C, the pressure is 10-20mbar, the speed is 180-230rpm, dehydrate, lower the temperature to 80-90°C, pass in an inert gas, and stir During the process, 22.5 parts of polyisocyanate are added, the temperature is raised to 90-110°C, and 1 part of catalyst is added for prepolymerization to obtain a prepolymer;

[0042] The polyhydroxy compound is polybutylene succinate, the molecular weight is 1000-3000g / Pmol, and the polyisocyanate component is diphenylmethane diisocyanate;

[0043] The catalyst is one or two mixtures of bismorpholino diethyl ether and dibutyltin dilaurate. Since the one-component polyurethane prepolymer requires long-term storage stability, bismorpholine diethyl ether and dibutylti...

Embodiment 3

[0049] Embodiment 3 A kind of one-component thermoplastic polyurethane adhesive and preparation method thereof, comprising:

[0050] 1. Preparation of polyurethane prepolymer

[0051] Put 180 parts of hydroxyl compound in a stirred tank, the temperature of the stirred tank is 100-120°C, the pressure is 10-20mbar, the speed is 180-230rpm, dehydrate, lower the temperature to 80-90°C, pass in an inert gas, and stir During the process, 25 parts of polyisocyanate are added, the temperature is raised to 90-110°C, and 2 parts of catalyst are added for prepolymerization to obtain a prepolymer;

[0052] The polyhydroxy compound is polybutylene succinate, the molecular weight is 1000-3000g / Pmol, and the polyisocyanate component is diphenylmethane diisocyanate;

[0053] The catalyst is one or two mixtures of bismorpholino diethyl ether and dibutyltin dilaurate. Since the one-component polyurethane prepolymer requires long-term storage stability, bismorpholine diethyl ether and dibutylti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com