High volume resistivity ptt composite material and preparation method thereof

A technology of high volume resistivity and composite materials, which is applied in the field of composite materials, can solve the problems that the volume resistivity and mechanical properties cannot meet the needs of reality and limit the application range, so as to improve creep resistance and reduce the amount of flame retardants , Improve the effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

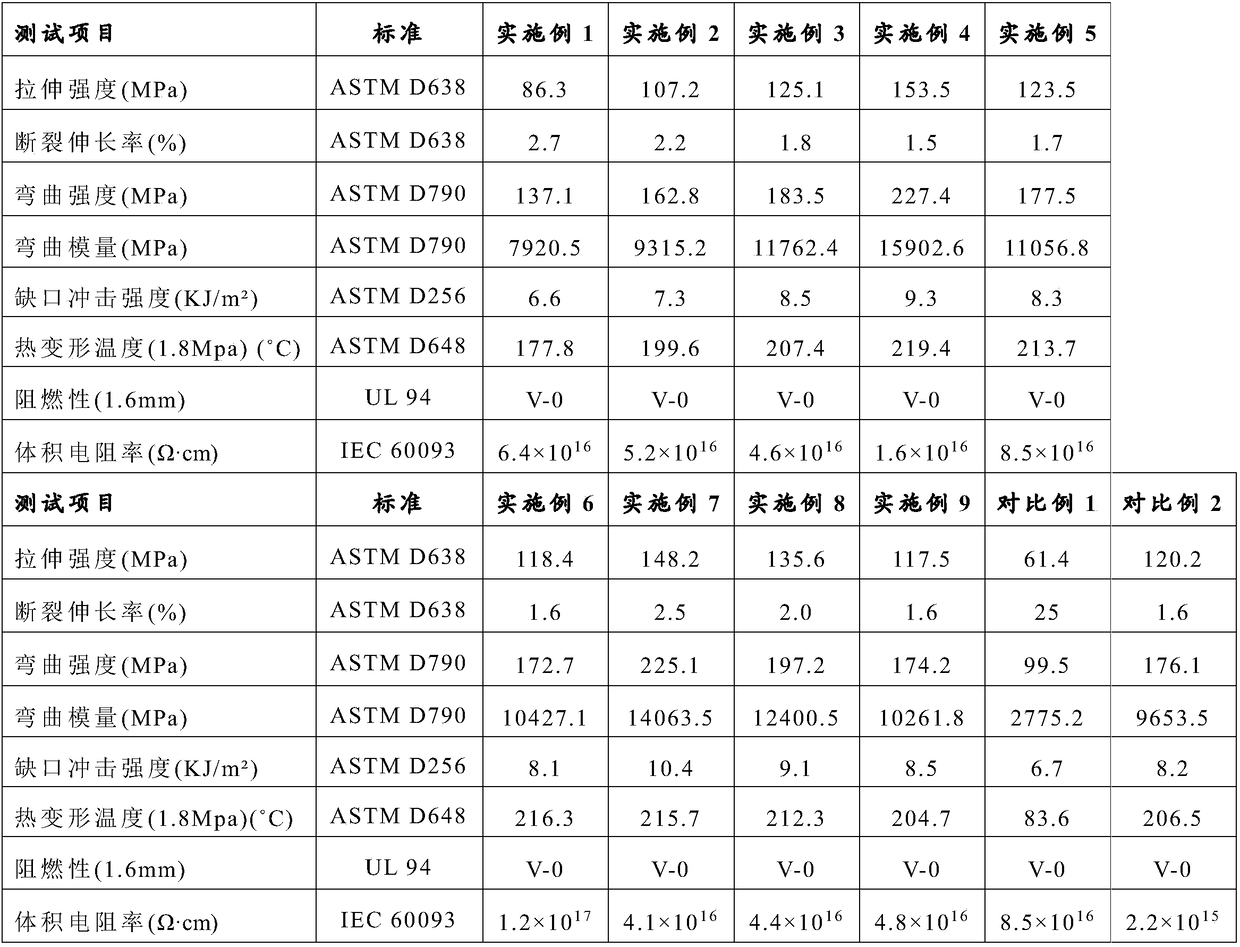

Examples

preparation example Construction

[0032] The preparation method of the high volume resistivity PTT composite material of an embodiment of the present invention, comprises the following steps:

[0033] Mix PTT, syndiotactic polystyrene, flame retardant, flame retardant synergist, compatibilizer, coupling agent, antioxidant, nucleating agent and other additives to obtain a premix, and mix the premix with The basalt fiber is extruded and granulated to obtain a PTT composite material with high volume resistivity.

[0034] Specifically, PTT and sPS can be dried at 100-130°C for 1-4 hours, and then the dried PTT and sPS, compatibilizer and coupling agent can be added to the mixer at a speed of 200-500 rpm Stir and mix for 1-3 minutes, then add flame retardant, flame retardant synergist, antioxidant, nucleating agent and other additives, stir and mix for 3-5 minutes at a speed of 200-500 rpm to obtain a mixed Homogeneous premix. Adding the premixture into a twin-screw extruder, adding basalt fiber, melting, extrudi...

Embodiment 1

[0038]After the PTT resin with an intrinsic viscosity of 1.0dl / g, a syndiotacticity of 97%, and a weight-average molecular weight of 300,000 sPS resin was air-dried at 120°C for 3 hours, 46 parts of PTT, 18 parts of Add sPS, 5 parts of compatibilizer ethylene vinyl acetate copolymer, 0.6 parts of silane ester coupling agent into the mixer, mix and stir for 1 minute at a speed of 300 rpm, and then add 16.6 parts of flame retardant after the mixer stops Agent brominated polystyrene, 3 parts of flame retardant synergist sodium antimonate, 0.2 part of antioxidant 1098, 0.2 part of antioxidant 626, 0.4 part of nucleating agent sodium benzoate in a mixer at a speed of 450 rpm Stir and mix for 3 minutes to obtain a homogeneous premix;

[0039] Place the premix in a twin-screw extruder and melt and extrude it under the following conditions: Zone 1: 180°C; Zone 2: 220°C; Zone 3: 240°C; Zone 4: 250°C; Zone 5: 240°C; Zone 6: 230°C; zone 220°C; zone 8 210°C; zone 9 220°C; machine head 24...

Embodiment 2

[0041] After the PTT resin with an intrinsic viscosity of 0.9dl / g, a syndiotacticity of 97.5%, and a weight-average molecular weight of 400,000 sPS resin was air-dried at 110°C for 4 hours, 45.4 parts of PTT, 10 parts of Add sPS, 2 parts of compatibilizer maleic anhydride grafted polyethylene-vinyl acetate copolymer elastomer, and 0.4 part of titanate coupling agent into the mixer, mix and stir for 2 minutes at a speed of 250 rpm, and wait for the mixer to stop Finally, add 16.6 parts of flame retardant brominated epoxy resin, 2.5 parts of flame retardant synergist antimony trioxide, 2 parts of flame retardant synergist montmorillonite, 0.3 part of antioxidant 1076, 0.3 part of antioxidant 168. Put 0.2 part of nucleating agent calcium monocarboxylate and 0.3 part of lubricant SEED in a mixer, stir and mix for 4 minutes at a speed of 300 rpm to obtain a uniformly mixed premix;

[0042] Put the premix in a twin-screw extruder and melt and extrude it under the following condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com