Self-circulation low nitrogen oxide swirling burner

A swirl burner, low nitrogen oxide technology, applied in the field of combustion, can solve the problems of blending, affecting the efficiency and life of the boiler, and achieve the effects of promoting blending, reducing heat loss and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

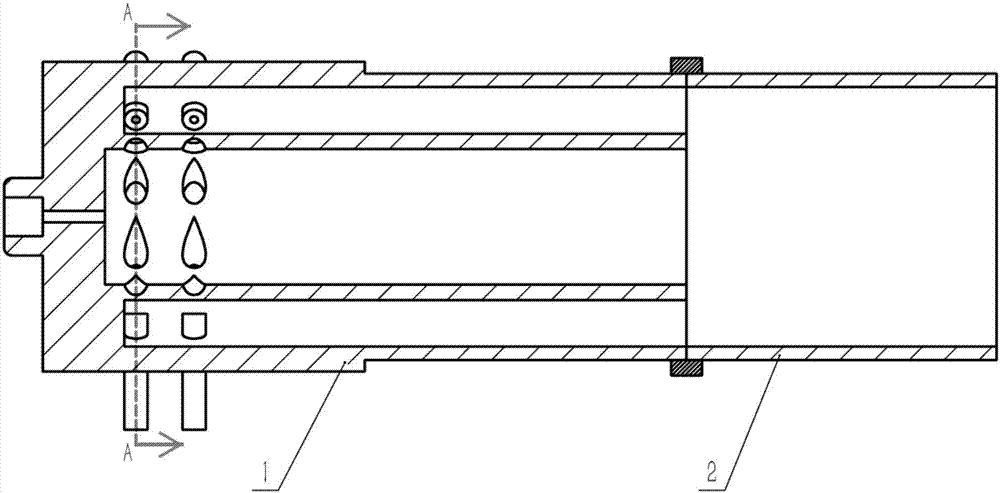

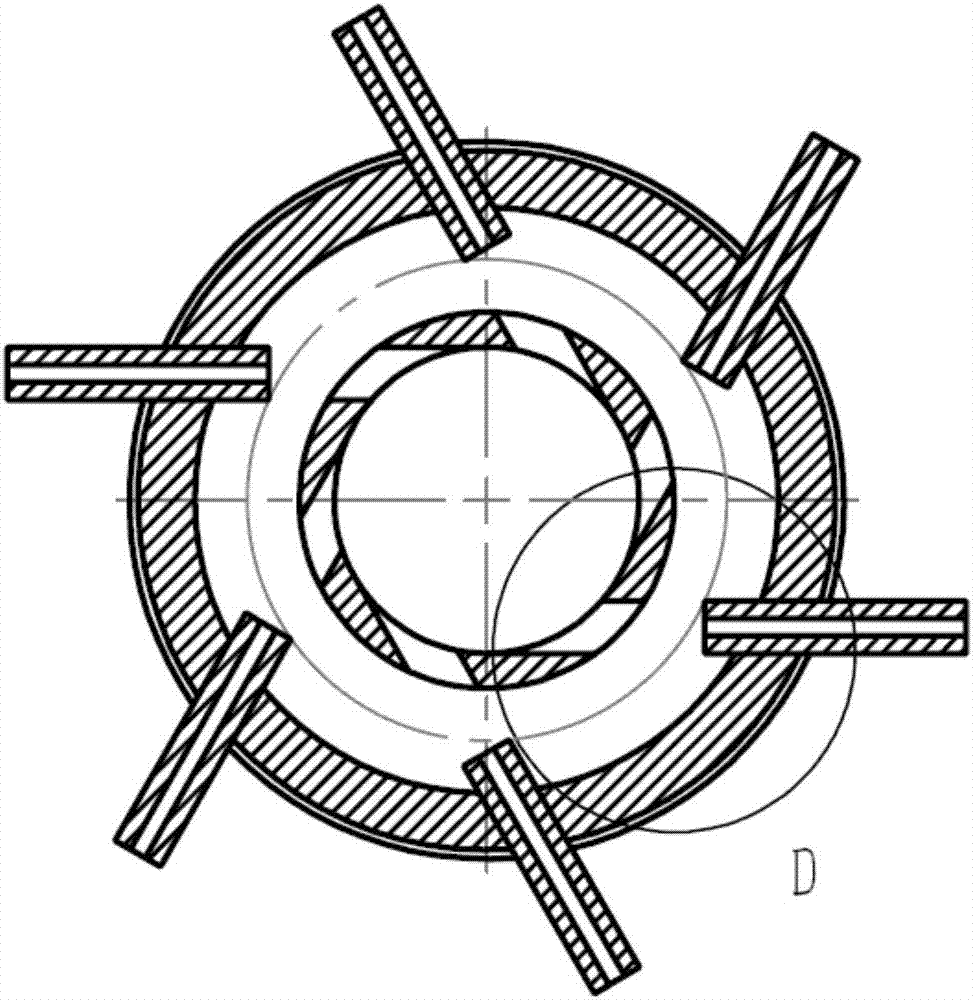

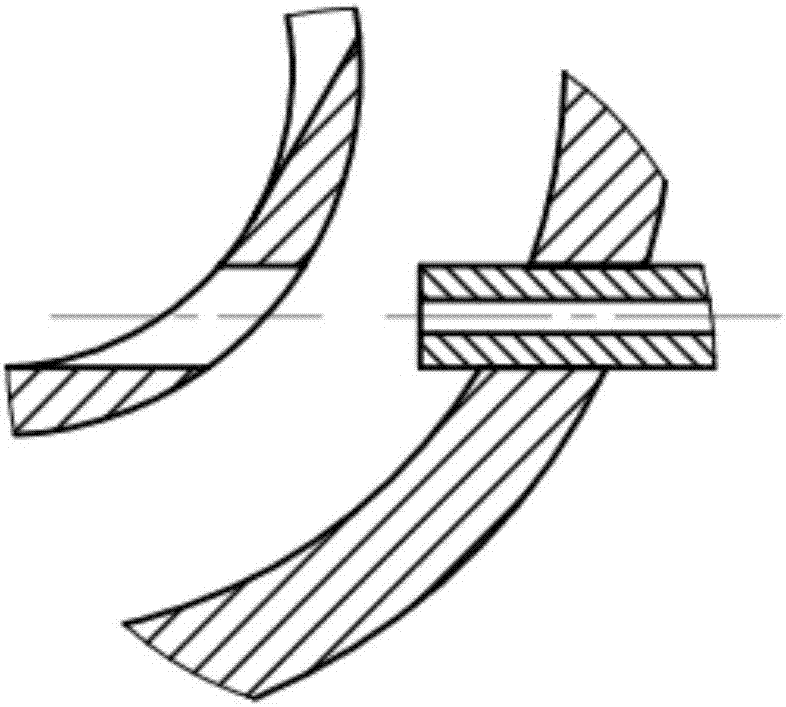

[0024] As shown in Figure 1, a self-circulating low-NOx swirl burner disclosed in this embodiment is mainly composed of a burner body 1 and a connecting pipe 2, and the burner body 1 and the connecting pipe 2 are installed concentrically. The main body of the burner 1 plays the role of mixing, combustion and gas circulation, and the connecting pipe 2 serves as an extension of the combustion chamber. The burner body 1 is mainly composed of an inner annular sleeve and an outer annular sleeve, and an annular cavity is formed between the inner annular sleeve and the outer annular sleeve. Such as figure 2 , 3 shown. The inner annular sleeve is the swirl frame, the inner space of the inner annular sleeve is the combustion chamber, and the swirl frame is provided with six tangential inner holes for swirling the gas in the combustion chamber. Six outer holes are opened on the outer annular sleeve for allowing air to flow in from the conduit, and the diameter of the outer holes is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com