Active control type fully-immersed liquid-cooled power battery thermal management system

A thermal management system and active control technology, applied in secondary batteries, battery temperature control, circuits, etc., can solve the problems of small latent heat of phase change, increase system volume, poor discharge rate cooling effect, etc., and achieve thinning heat transfer boundaries Layers, enhanced perturbation and blending, system-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

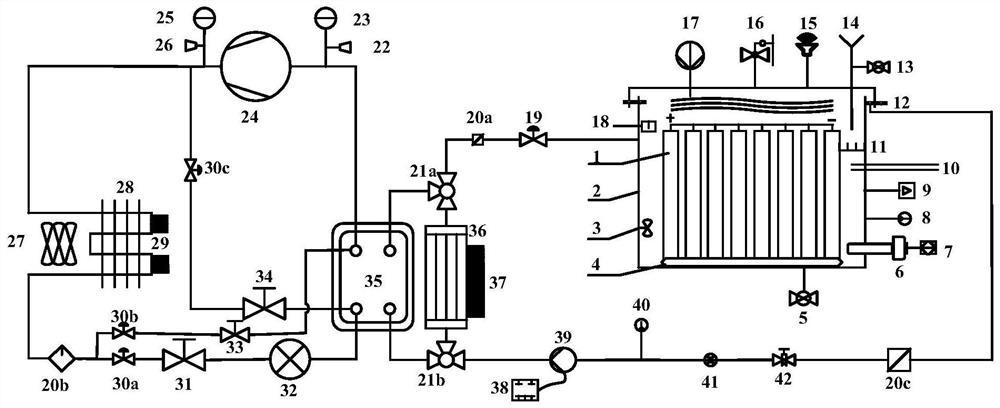

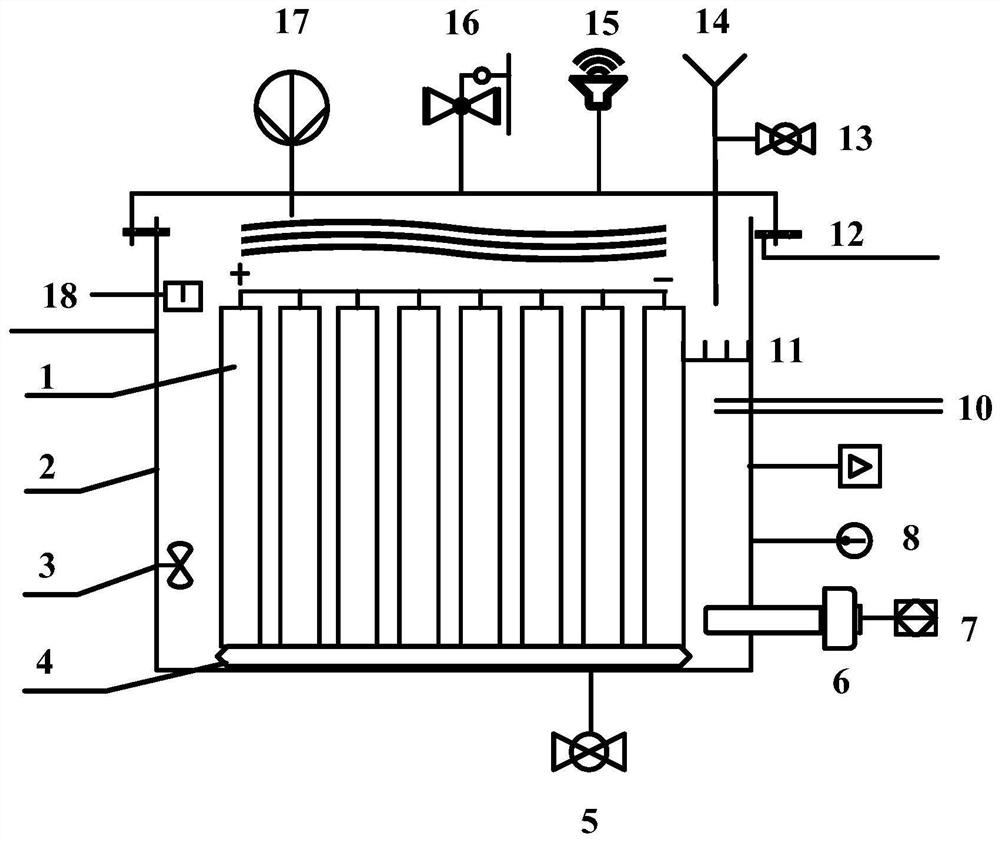

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] combine Figure 1-2 , the present invention provides an active control type fully submerged liquid-cooled power battery thermal management system, by directly and completely submerging the power battery in the coolant tank, the insulating refrigerant directly contacts the power battery, and there is no secondary liquid cooling plate or the like in the middle Secondary circuit liquid cooled components. The direct contact full immersion cooling method can greatly reduce the heat transfer resistance of the thermal management system and increase the heat transfer coefficient; at the same time, the agitator is used to strengthen the turbulence of the refrigerant in the coolant tank, which can enhance the heat transfer effect of the entire thermal management system.

[0020] Such as figure 1 As shown, an active control type fully submerged liquid-cooled power b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com