Special equipment for rubbish fermentation and rubbish fermentation method

A special device and fermentation technology, which is applied in the field of dynamic aerobic rapid biological fermenter and corresponding fermentation method, can solve the problems of large temperature fluctuation, increased cost, and inability to adjust, so as to improve the filling factor, improve production efficiency, The effect of small temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

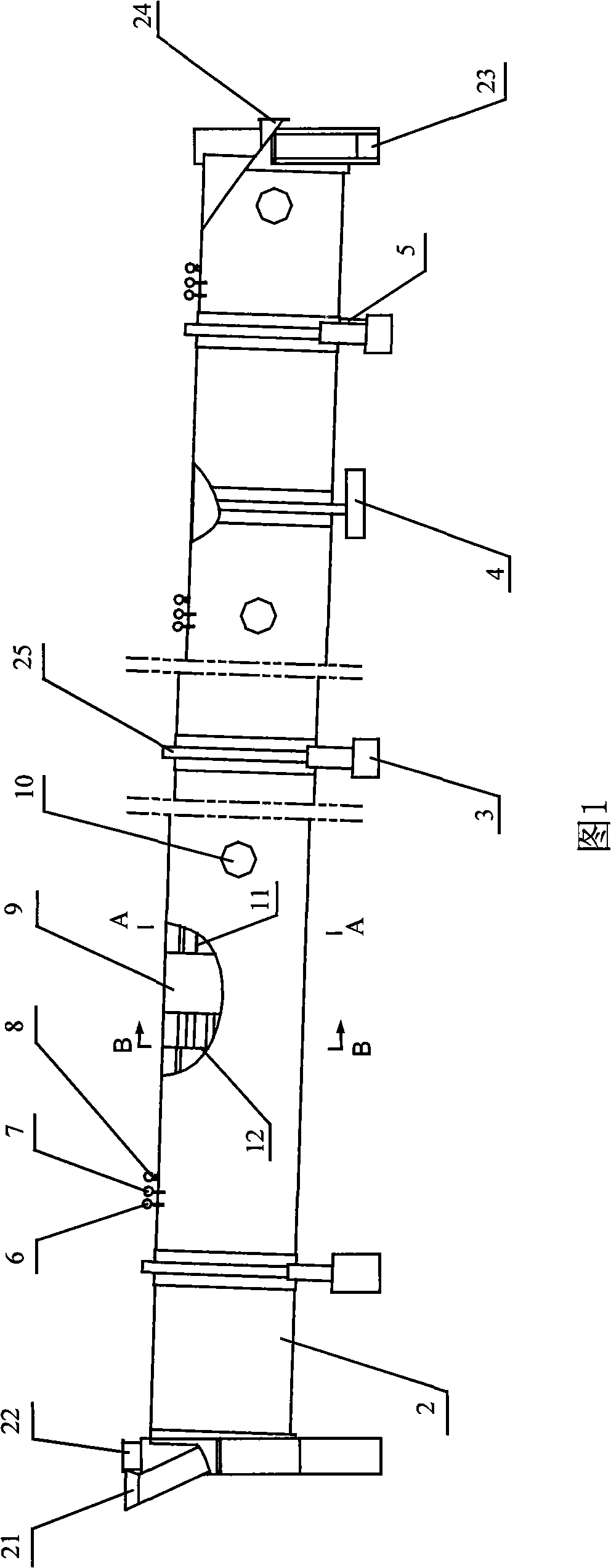

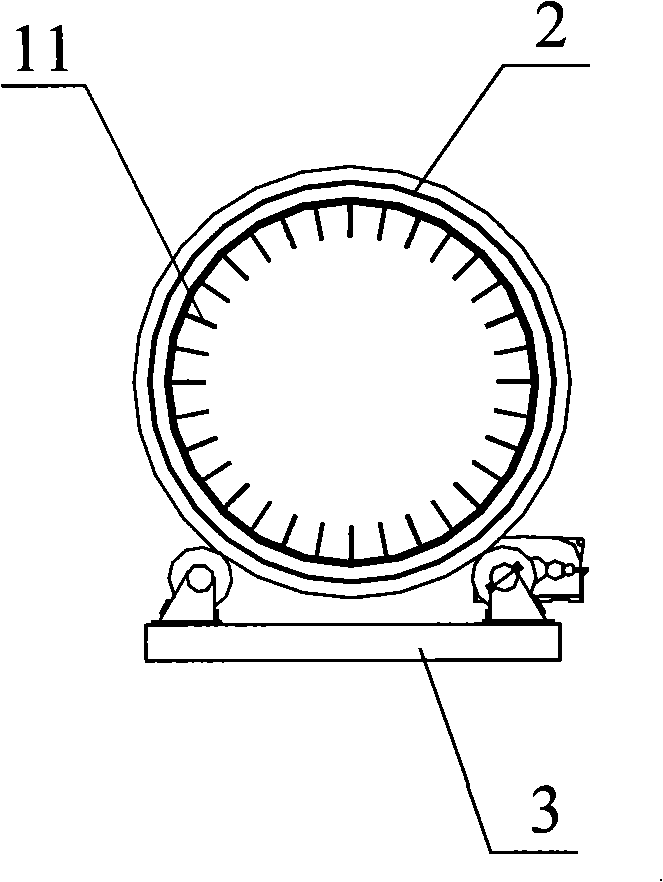

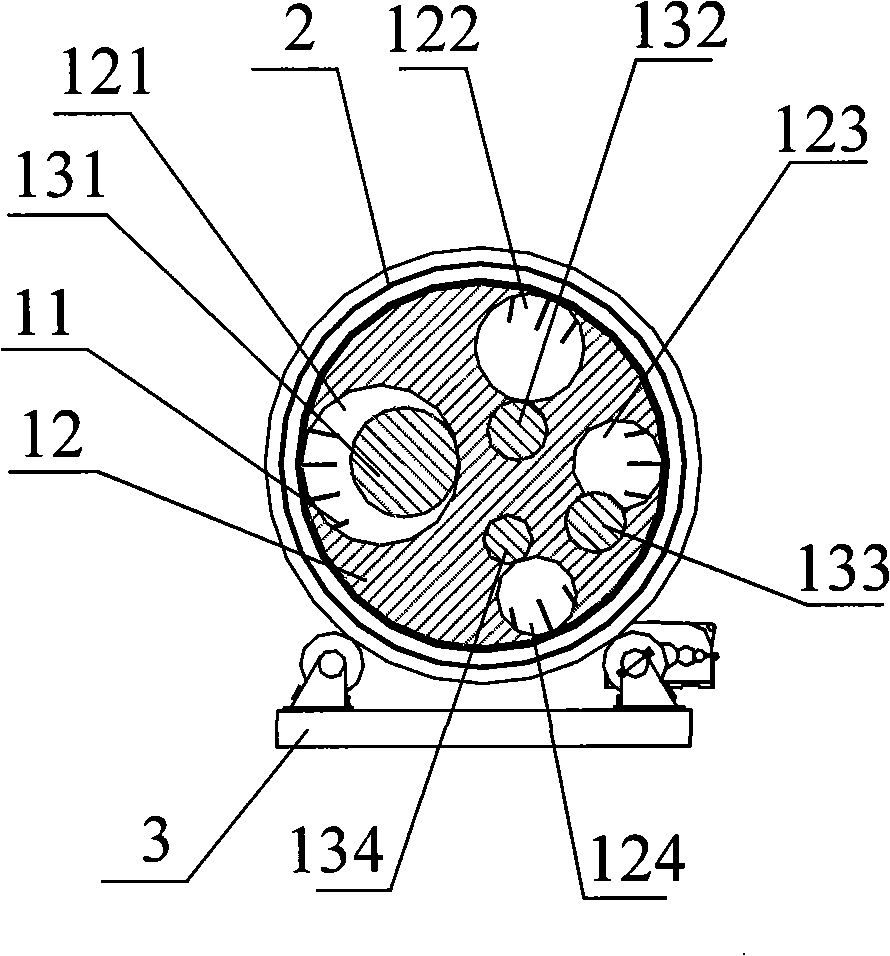

[0029] figure 1, figure 2 with image 3 Combined with a special device for garbage fermentation, it includes a hollow fermentation cylinder 2, which is made of steel plate, and its inner cavity is 32 meters long and 3.2 meters in diameter, that is, the volume is 258m 3 . A feed inlet 21 and an air outlet 22 are respectively provided at the left end of the fermentation cylinder 2 , and a material outlet 23 and an air inlet 24 are respectively provided at the right end of the fermentation cylinder 2 . The angle between the central axis of the fermentation cylinder 2 and the horizontal plane is 2°; thus the left end of the fermentation cylinder 2 is higher than the right end. The driving mechanism 4 is connected with the fermentation cylinder 2 so as to make the fermentation cylinder 2 rotate. The outer surface of the fermentation cylinder 2 is provided with 3 groups of outer toothed gears 25, and the 3 groups of supporting wheel frame assemblies 3 are just connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com