Juice and residue separation mechanism and low-speed juice extractor including same

A juice separation and juicing cup technology, which is applied to household machinery for filtering food, household appliances, applications, etc., can solve problems such as ineffective wear defects, metal powder is harmful to the human body, and expensive products, and achieve structural Simple, easy to clean and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

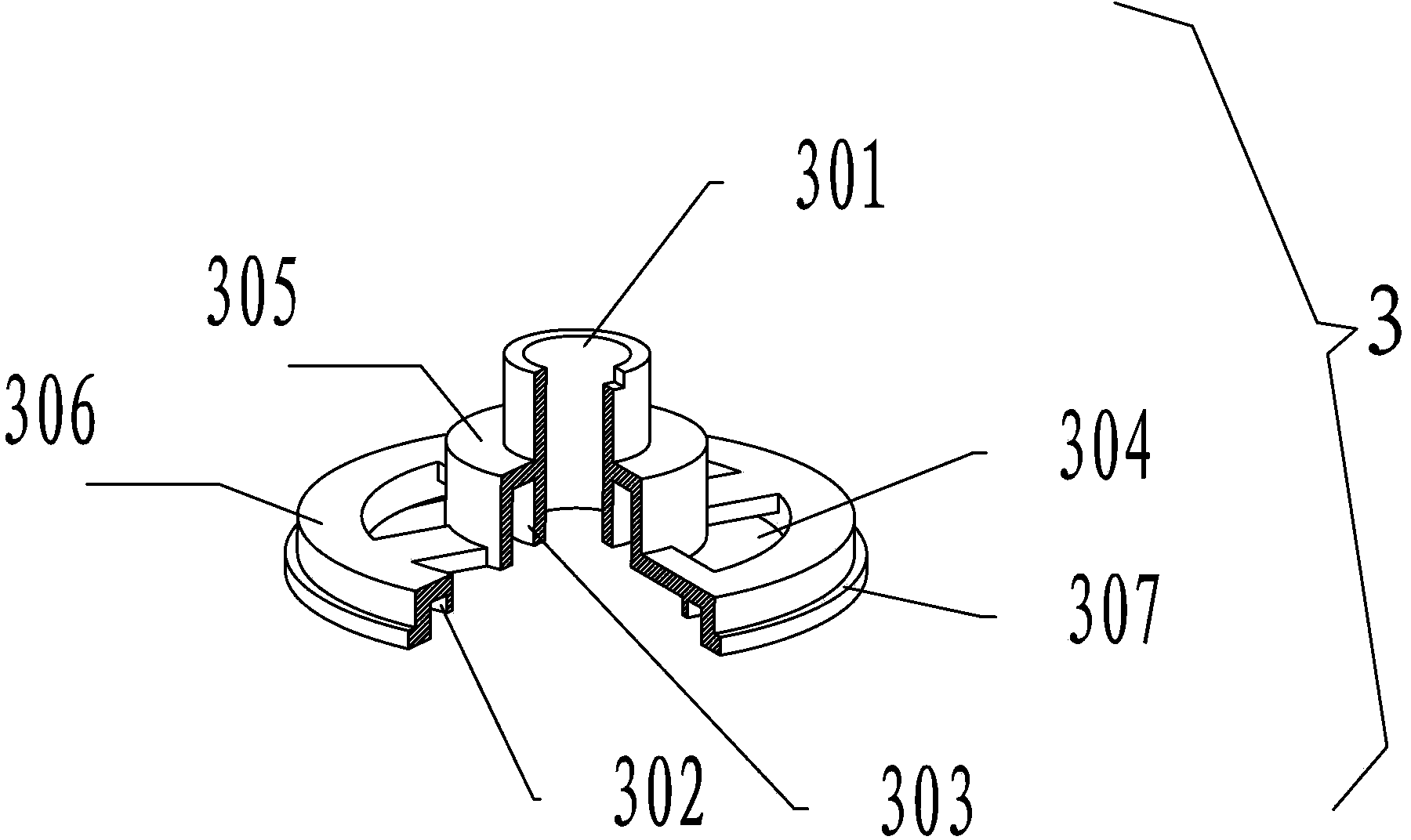

[0025] Such as Figures 1 to 4 As shown, the juice slag separation mechanism of the slow juice extractor of the present embodiment includes: a cup cover 1, a juice extraction cup 4 matched at the lower end of the cup cover 1, a filter frame 2 and a juice guide frame 3 arranged on the juice extraction cup 4 in.

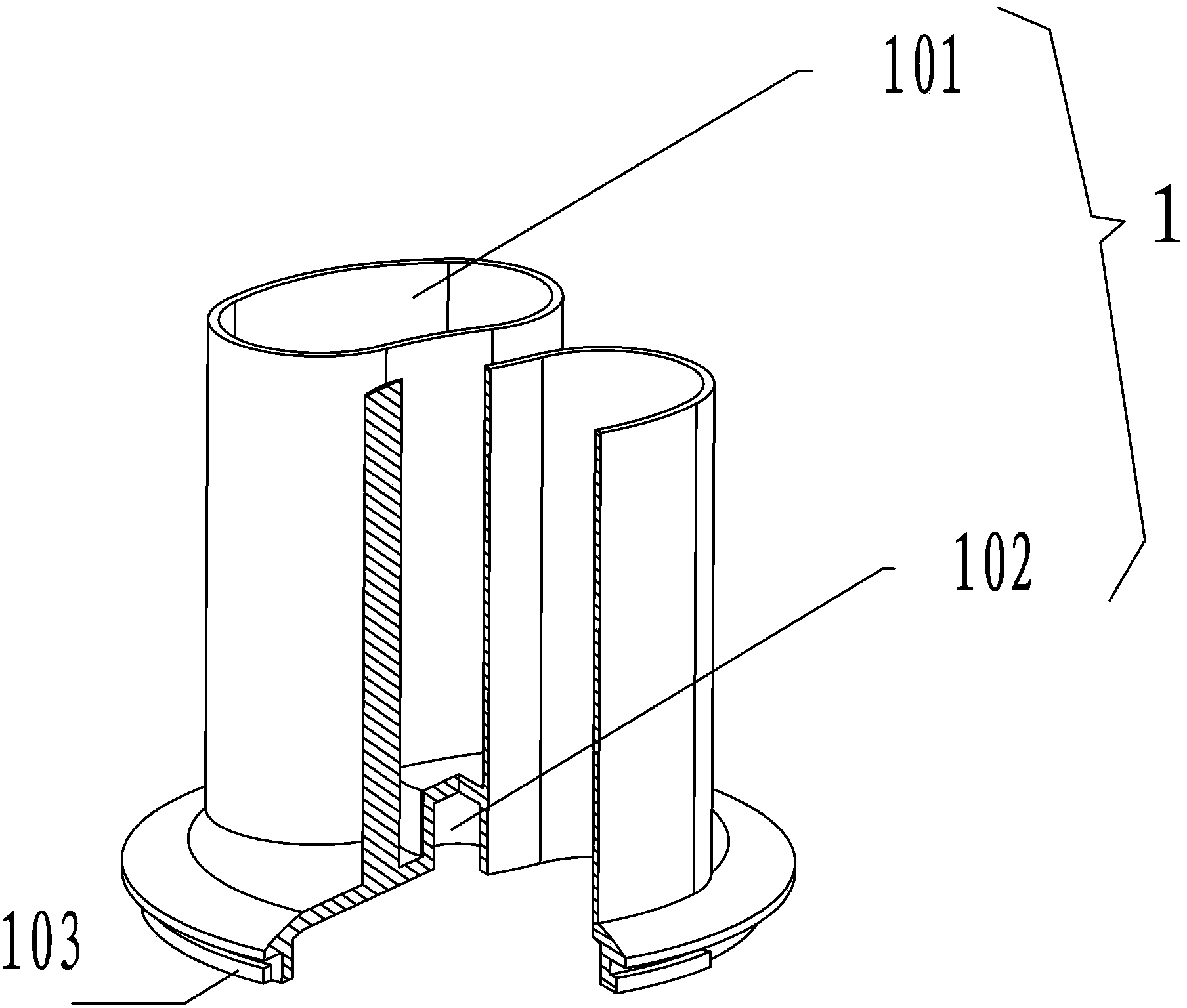

[0026] Bowl cover 1 is vertically provided with two cross-sections that are elliptical and annular columnar material inlets 101, which are beneficial to fast feeding and convenient use; Locking thread 103 is arranged.

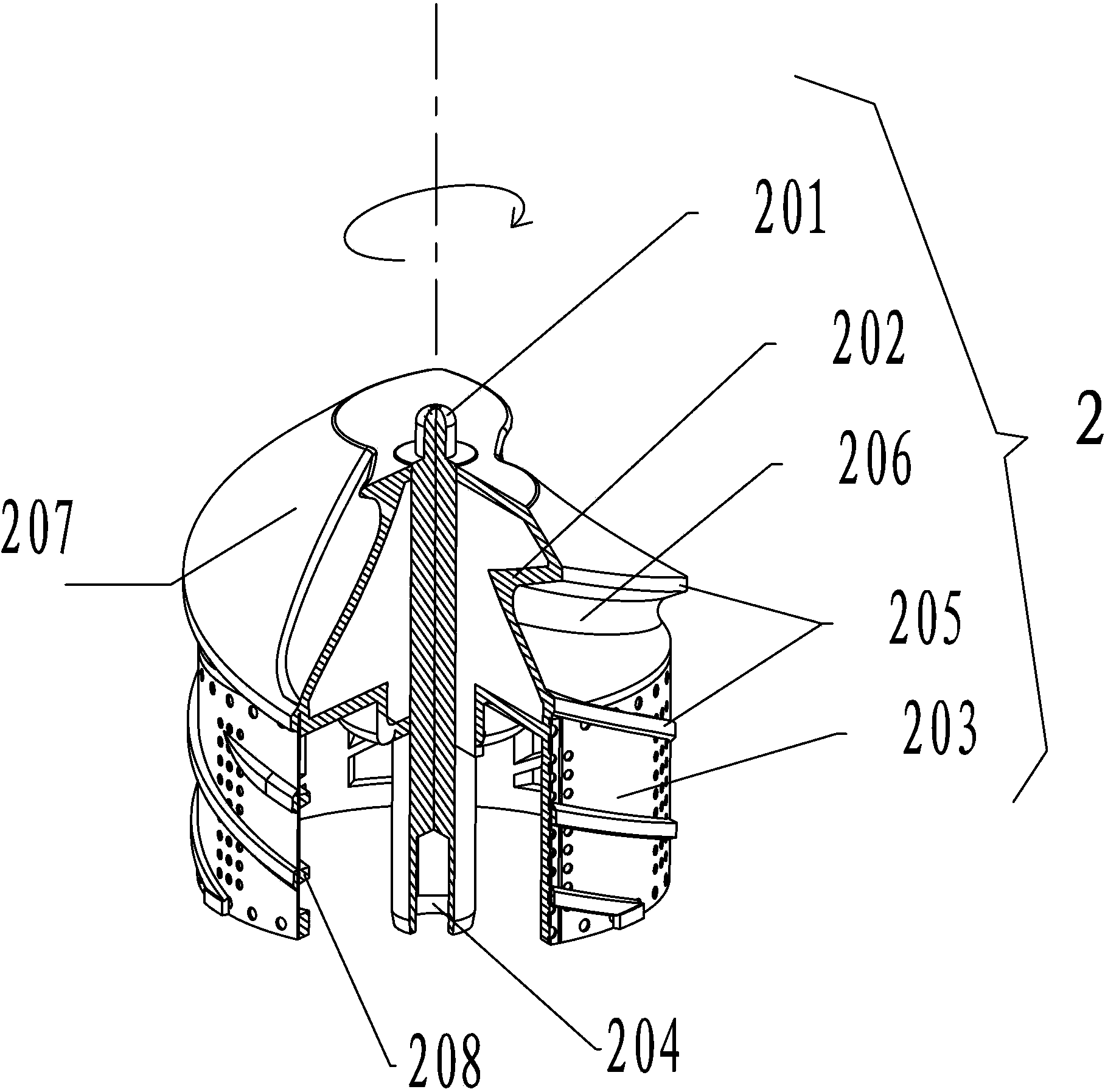

[0027] The separator 2 comprises a drive shaft 201 and a hollow cover 202 around the drive shaft. The drive shaft 201 is connected to the hollow cover 202 through a reinforcing rib. The hollow cover 202 includes a hollow cylindrical filter screen 203, which is injection molded with the filter screen 203. An integral top 207 and a spiral rib 205, the spiral rib 205 is distributed on the outer surface of the filter screen 203, and is used to squeeze the...

Embodiment 2

[0033] A slow juice extractor in this embodiment includes the juice dregs separation mechanism in Embodiment 1 above.

[0034] Such as Figures 6 to 7 As shown, the slow juice extractor also includes: a driving mechanism 5, a motor is arranged in the driving mechanism 5, the top of the rotor of the motor is exposed and a connecting head 501 with a hexagonal section is provided, and the top of the driving mechanism 5 is provided with a buckle 502 and The slot provided at the bottom of the juicer cup 4 cooperates and fixes; the connecting head 501 cooperates with the second blind hole 204, so that the motor can drive the driving shaft 201 and the hollow cover 202 to rotate.

[0035]The working method of the above-mentioned slow juice extractor includes: starting the motor and driving the drive shaft 201 to rotate, and then driving the hollow cover 202 to rotate; Under the action of rotation, it enters the rolling groove 206 for rolling, and moves down along the rolling groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com