Isothermal Local Loading Forming Method for Complex Integral Members of Titanium Alloy Large Ribbed Plates

A technology of isothermal local loading and integral components, applied in the direction of metal processing equipment, etc., can solve the problems of reduced mechanical properties of components, high cost of formed components, low material utilization rate, etc., achieve small metal deformation resistance, improve filling performance, and reduce defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

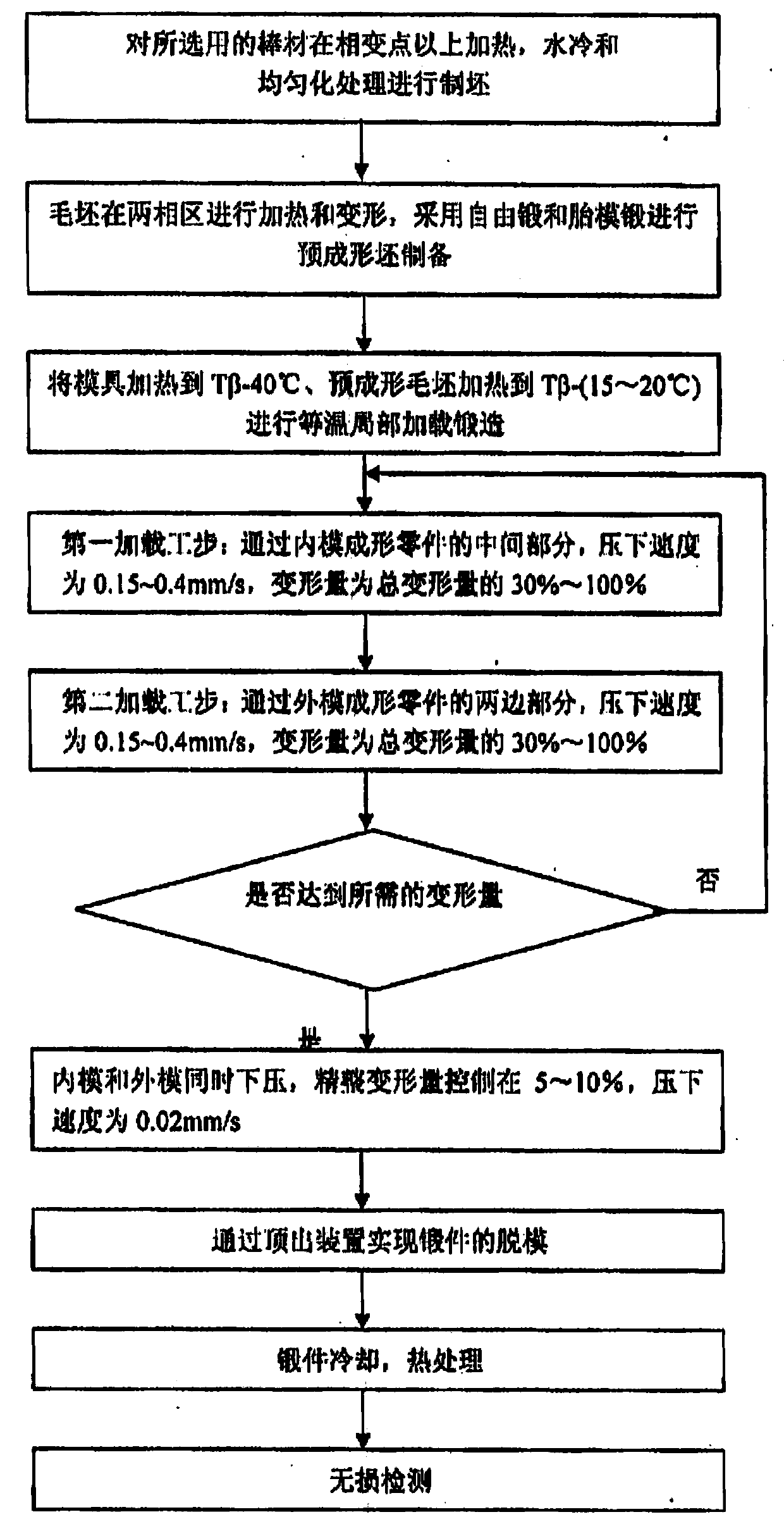

[0026] Step 2. Preparation of preformed blank. The blank is heated and deformed in the two-phase region, and the alloy is heated to T β -40°C, use free forging and tire die forging to make billets.

[0027] Step 3, isothermal local loading forming. The forming process adopts the local forming method of the workpiece, and carries out isothermal local loading on an 8,000-ton hydraulic press. In order to ensure that the required load does not exceed the maximum tonnage of the equipment during the loading process, the workpiece is loaded in two areas. The total reduction is 30mm, and one loading pass is adopted, in which the loading deformation is 25mm, and the finishing deformation is 5mm. The preform is heated in a box-type resistance furnace to T β -15°C, and keep warm for 1.5h. The mold is heated to T β -40°C, and keep warm for 2h. The middle part of the workpiece is formed by the internal mold. During the forming, it is pressed down at a speed of 0.15 mm / s, and the amo...

Embodiment 2

[0033] In this embodiment, a steel company has 8,000 tons of hydraulic equipment in China, and the production outline size is 1.5×1.5m 2 , the TA15 titanium alloy integral stiffened plate member with a weight of 115 kg adopts an isothermal local loading mold consisting of an inner mold and an outer mold to form an upper mold. The local loading and forming of the forging is realized by controlling the movement of the outer mold and the inner mold. The specific process is :

[0034] Step 1, blank preparation. The selected bar is heated above the phase transition point, water-cooled and homogenized; the electroslag ingot is forged into an alloy billet with a height-to-diameter ratio of 2.4 to 2.7 by using the conventional upsetting method; the surface of the cylinder is polished, and the defect is localized polished.

[0035] Step 2, the preparation of the preformed blank. The blank is heated and deformed in the two-phase region, and the alloy is heated to T β -40°C, use free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com