Industrial sartorius electromotor shell

A technology for industrial sewing machines and motor casings, which is applied to electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems of not using casings, and the stator iron core is too large, so as to save raw materials and fuselage structure. Small, weight saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Please refer to the accompanying drawings for a further description of the present invention.

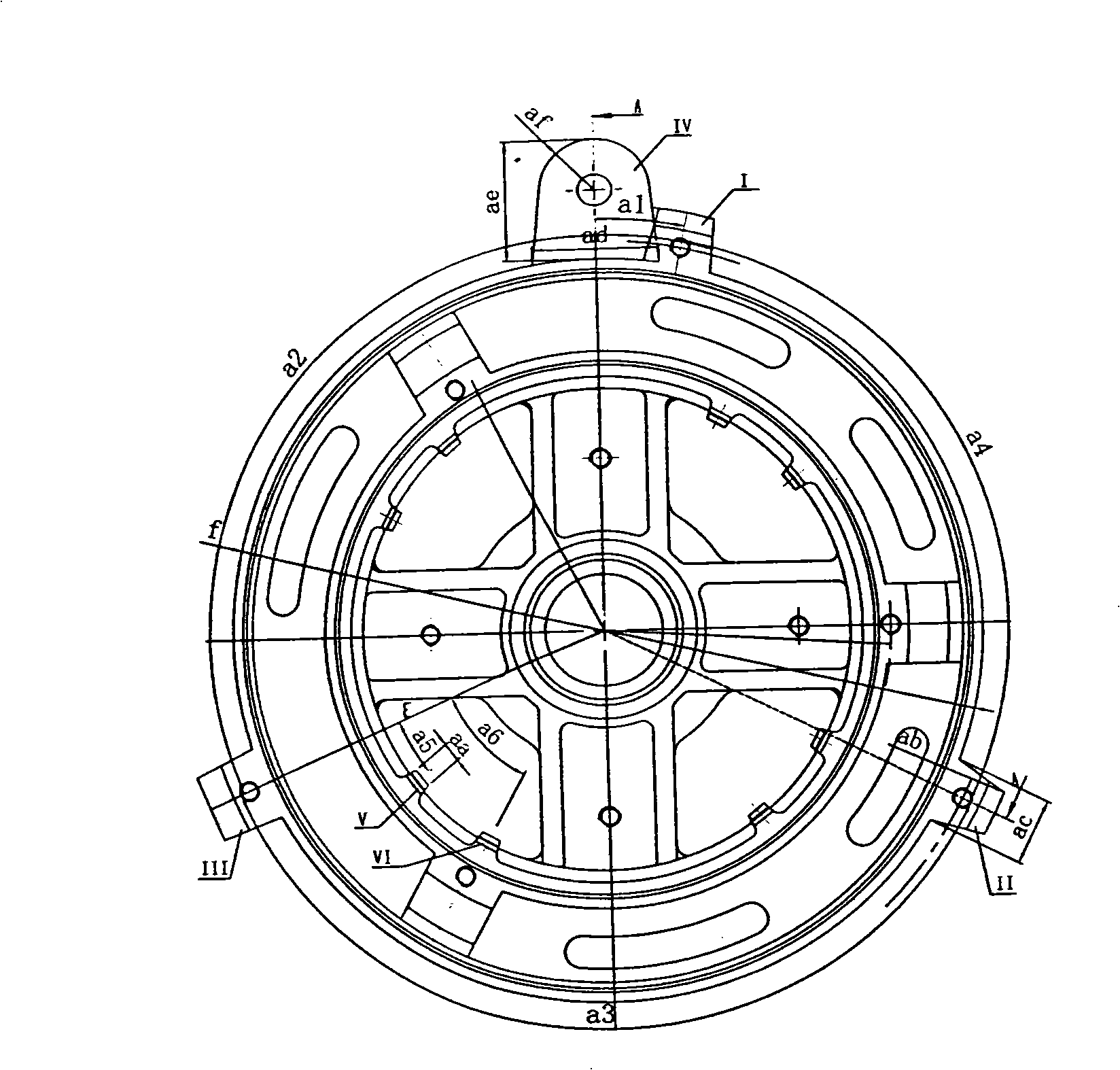

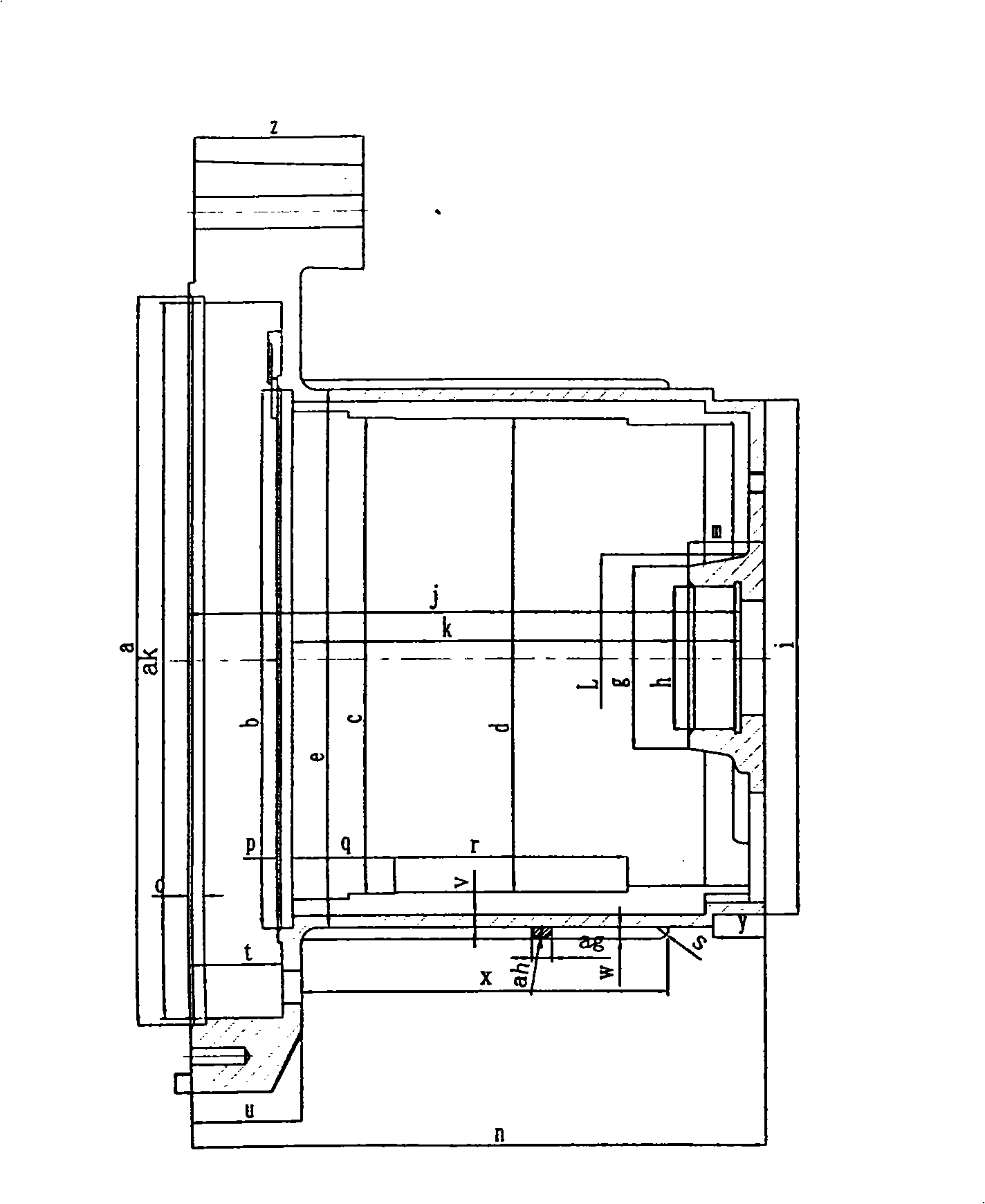

[0017] like figure 1 and figure 2 As shown, the entire structure of the motor casing is directly cast and formed, which is two hollow cylinders, one is a large cylinder, and the other is a small cylinder. The outer layer of the small cylinder is evenly distributed with several small ribs, and the inner wall is evenly distributed with several Large ribs, one end of a small cylinder is the bottom, closed in a cross shape, and there is a conical truncated cone protruding inward at the center of the bottom.

[0018] The outer circumference of the large cylinder is distributed with three outwardly protruding bosses I, II, III, and a big boss IV, the radial centerline angle a1 between the big boss IV and the small boss I, Be 12 °, the shoulder surface of large cylinder has ventilation groove 1.

[0019] The angles a2, a3, and a4 between the three small bosses I, II, and III are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com