Method for detecting surface contact area between inner ring of tapered roller bearing and roller ball base

A tapered roller and detection method technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as user returns, high bearing temperature rise, early failure, etc., and achieve the effect of avoiding measurement errors, low proficiency requirements, and accurate contact areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in conjunction with accompanying drawing and specific embodiment:

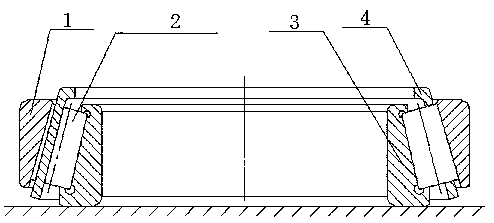

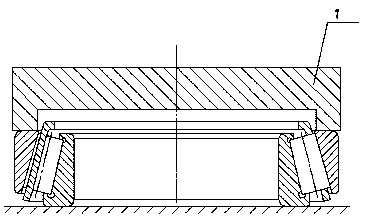

[0015] Such as figure 2 shown, combined with figure 1 , a detection method for the contact area between the inner ring of the tapered roller bearing and the surface of the roller ball base surface. Fine powder (alumina, aluminum hydroxide, cerium oxide, diamond, calcium carbonate, silicon carbide, etc.) The grinding powder on the wear-resistant cloth forms the abrasive for grinding the tapered roller 2; select three standard tapered rollers 2, and then rotate the ball base surface of the three standard tapered rollers on the grinding cloth for 1 to 2 Make the spherical base surface of the tapered roller 4 stick the grinding powder of the grinding cloth; place the small end of the cage 4 facing down on the workbench, and place the big end of the three standard tapered rollers 2 with the grinding powder on it Face up and evenly distribute in the window hole of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com