Heat exchanger

A heat exchanger and heat exchanger tube technology, applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve the problems of small rib coefficient, poor heat exchange performance, small heat transfer area, etc. The effect of large rib coefficient, ingenious design and large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

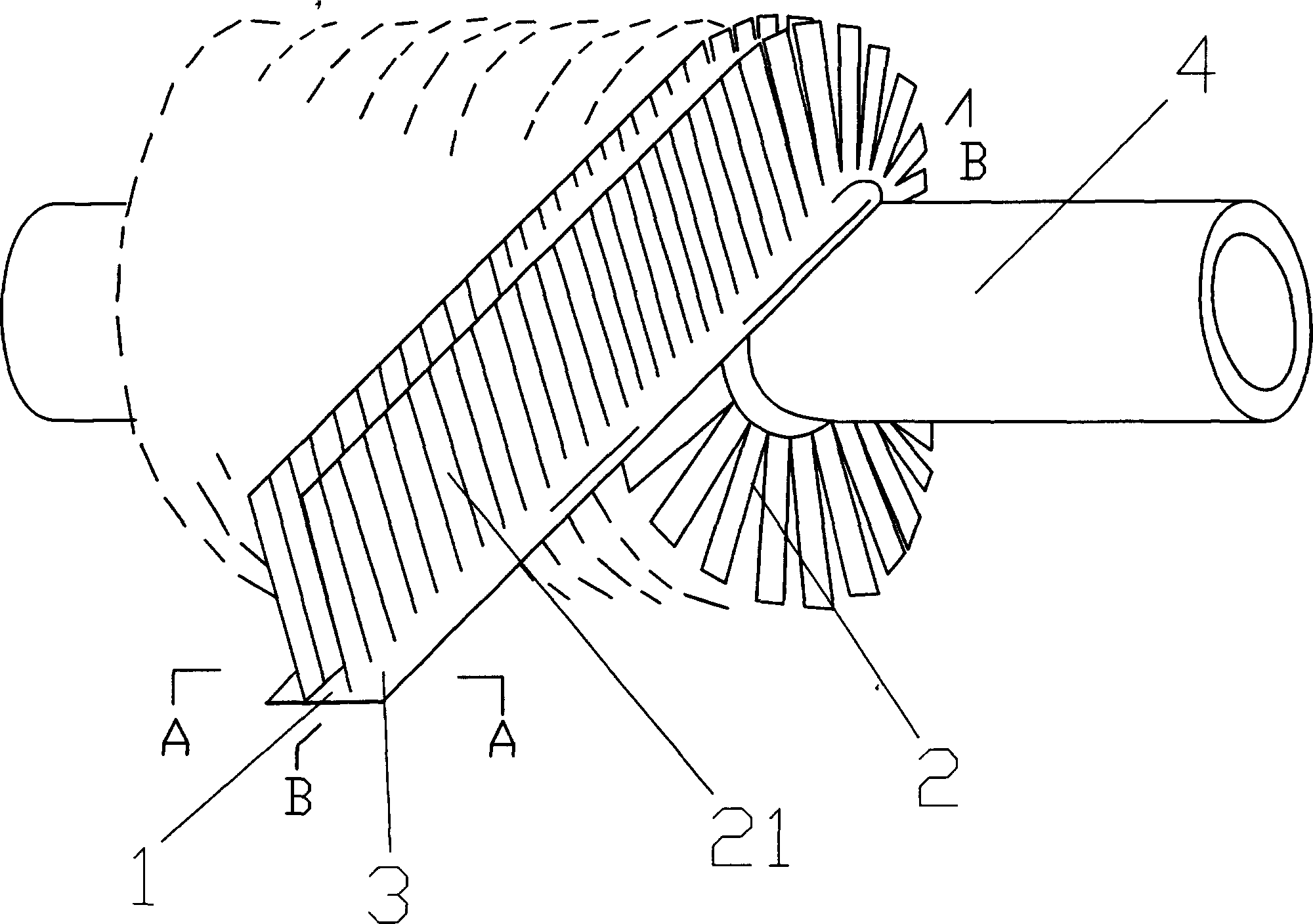

[0014] The structure diagram of the present invention is as figure 1 As shown, it includes a heat exchanger tube 4 and fins 2 arranged on the heat exchanger tube 4 , wherein the fin 2 is a strip-shaped fin fixed on the outer surface of the heat exchanger tube 4 in a spiral shape.

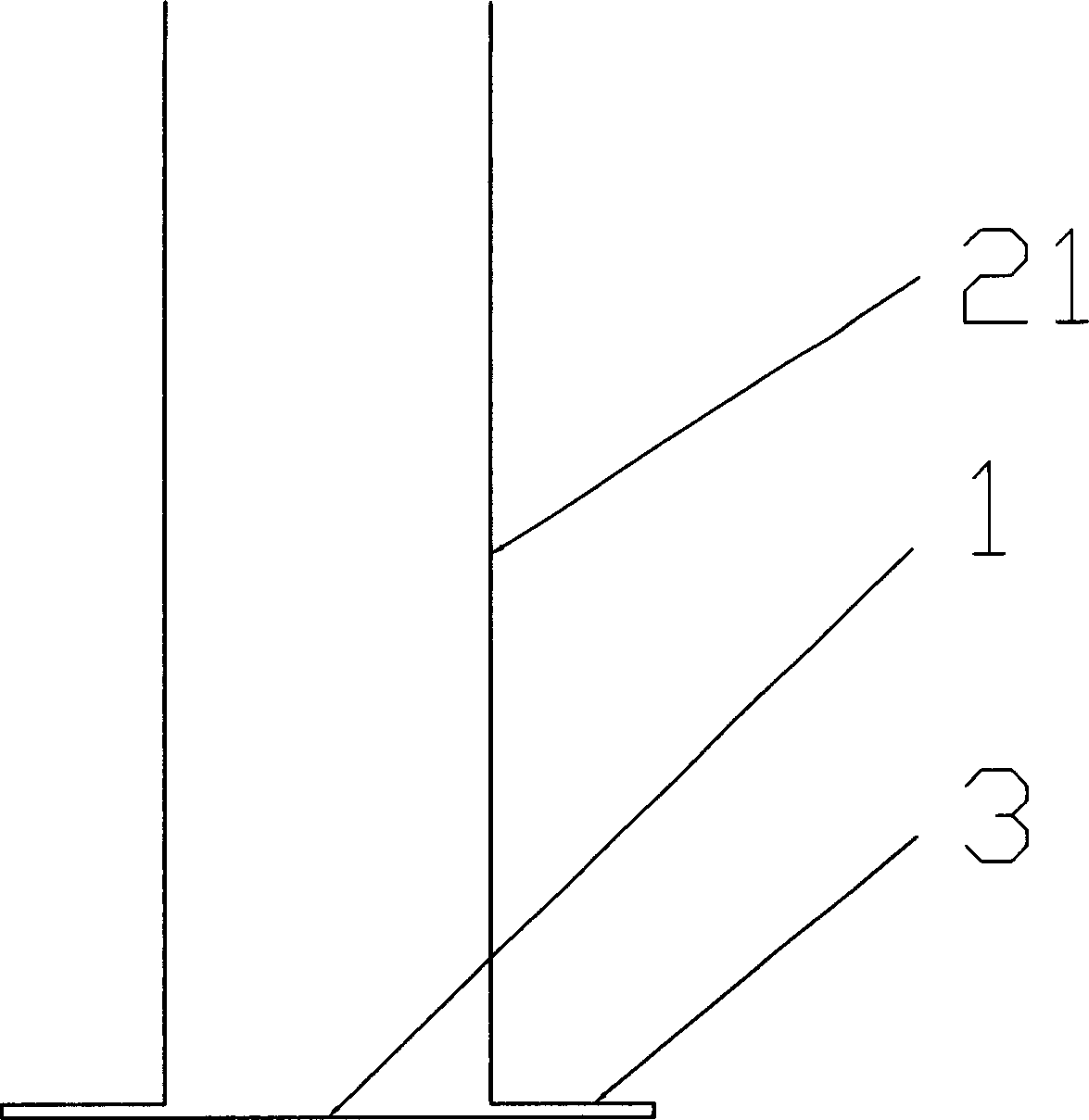

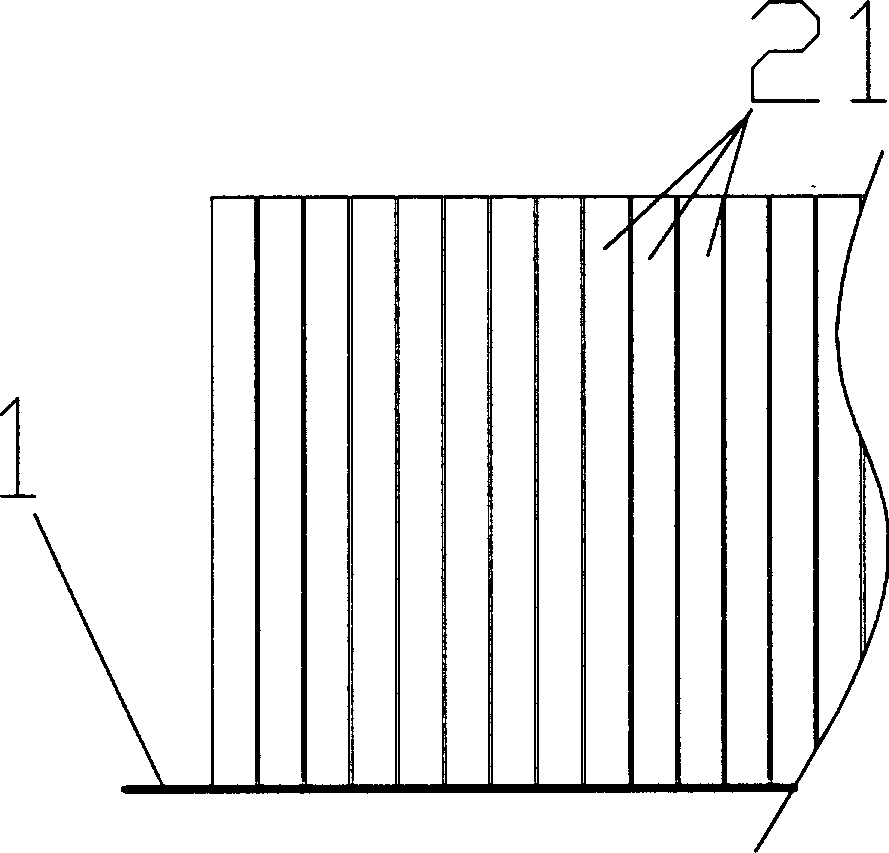

[0015] For ease of installation, the above-mentioned strip fins 2 include a substrate 1 and a plurality of fins 21. The plurality of fins 21 are erected and fixed on the substrate 1, and then spirally wound on the heat exchanger tube 4 through the substrate 1. .

[0016] In order to ensure the uniformity of heat exchange in the present invention, the plurality of fins 21 are fixed on the substrate 1 at equal intervals along the circumferential direction.

[0017] In order to further increase the installation speed, thereby improving the productivity of the present invention, the substrate 1 is fixed with several rows of fins 21 arranged at equal intervals in the axial direction, such as two or thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com