Electromagnetic forming device and forming method for aluminum alloy rib plate

An electromagnetic forming and aluminum alloy technology, which is applied in the field of rib plate material processing, can solve the problems of difficult forming, insufficient molding, and easy instability of ribs, etc., and achieves small forming springback, good surface quality, and rib plate molding good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

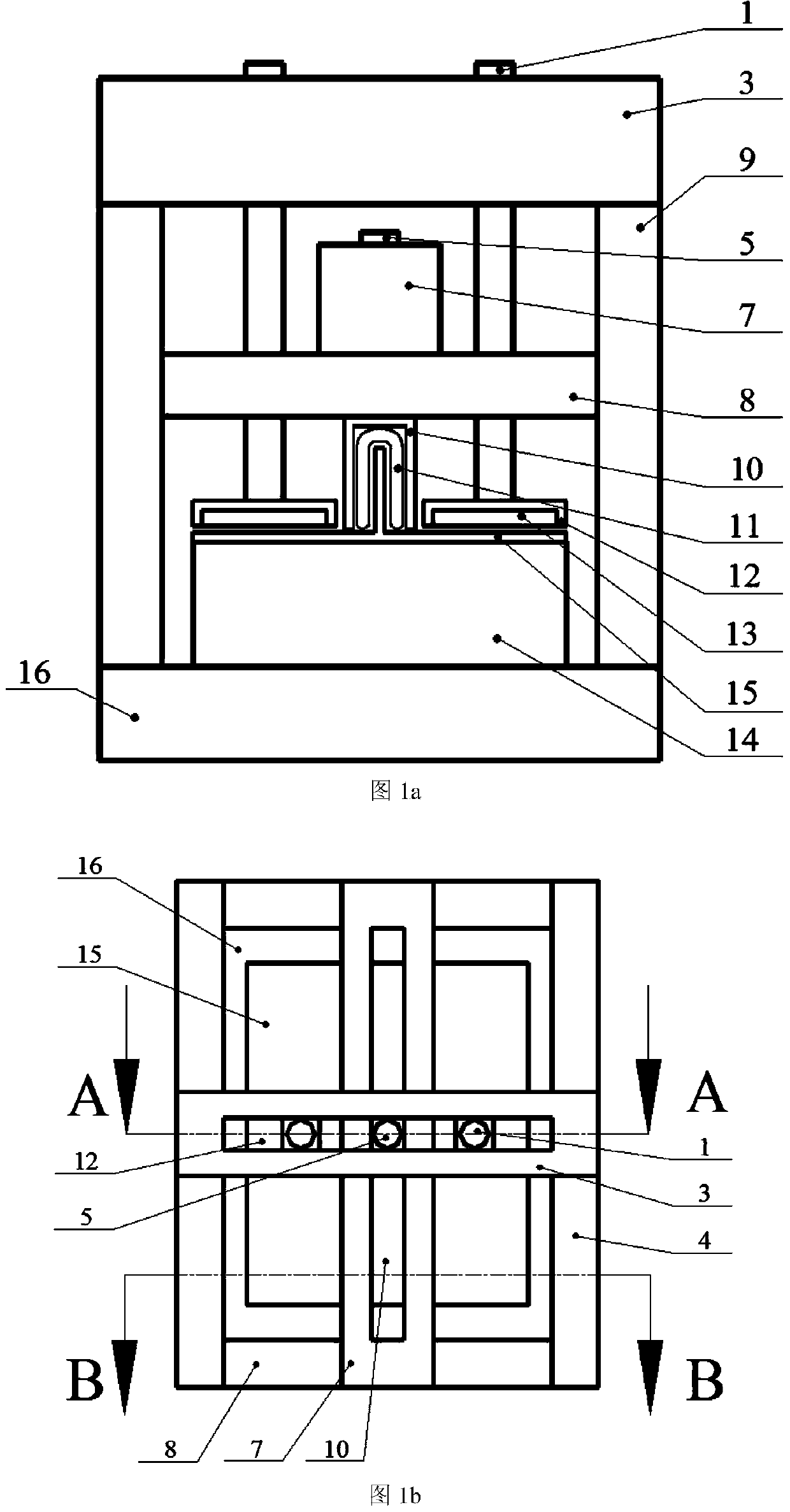

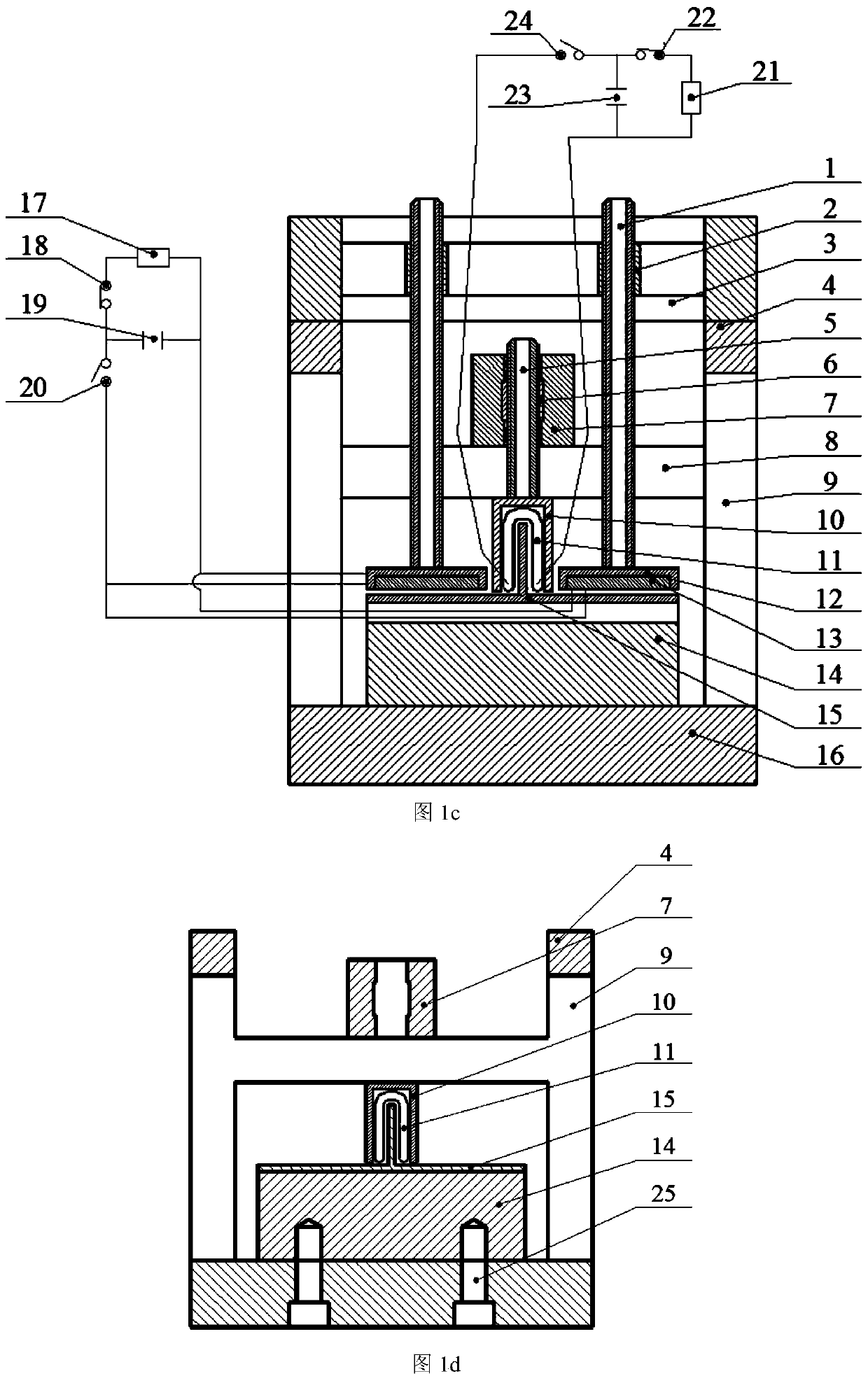

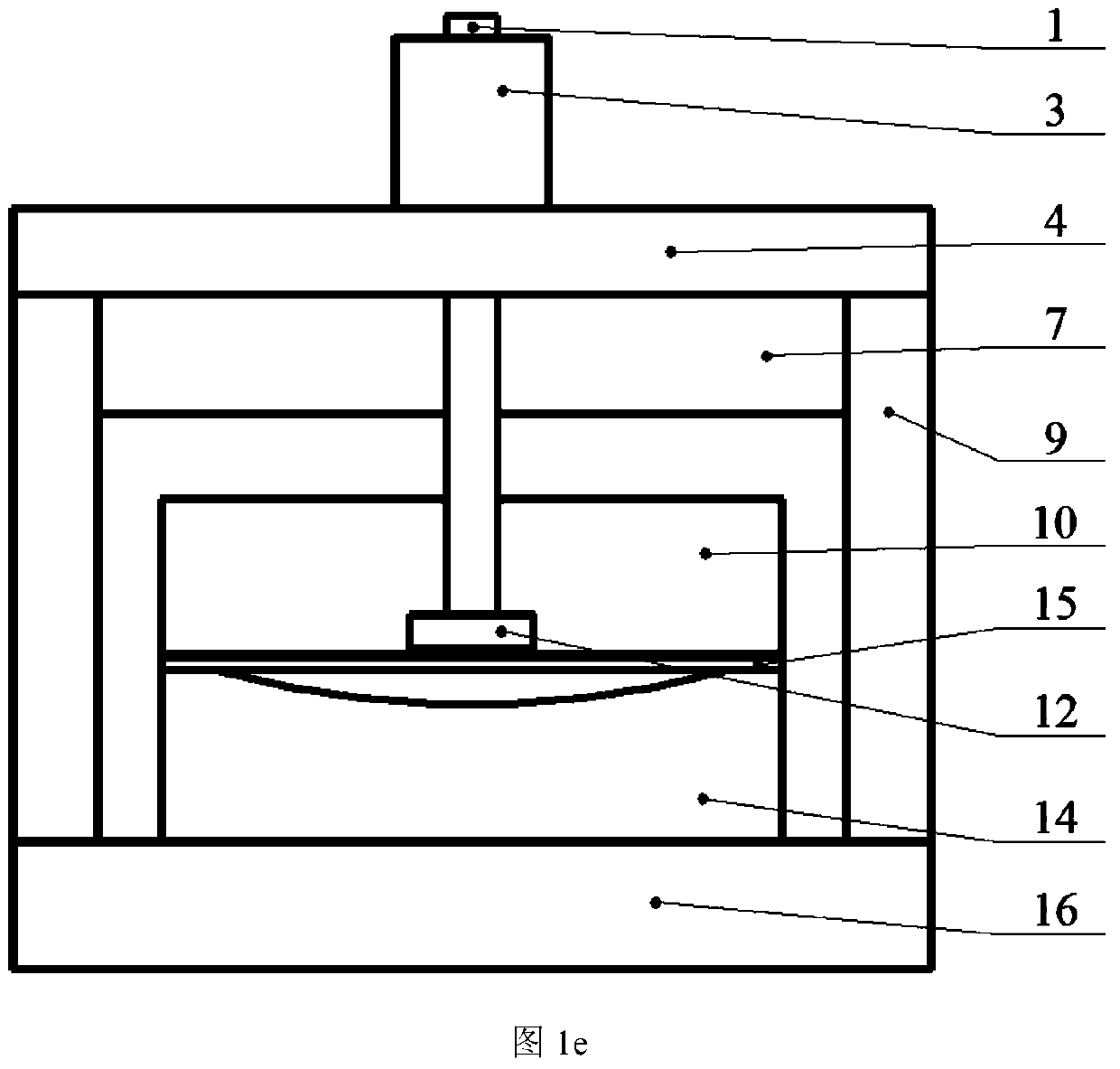

[0049] This embodiment is an electromagnetic forming device for an aluminum alloy stiffened plate, which is used to realize simultaneous bending of ribs and webs of a stiffened plate and a device and method thereof.

[0050] The aluminum alloy rib plate 15 is made of 7050 aluminum alloy material, which is composed of ribs and webs, and its cross section is T-shaped. The ribs are distributed along the length of the web, the thickness of the ribs is 2-5mm, the height of the ribs is 10-60mm, and the height-thickness ratio of the ribs is 5:1-15:1, and the thickness of the web is 1-4mm. The overall length of the ribs is 100-900mm, and the width is 60-800mm. In this embodiment, the ribs 15 are placed on the die 14, the ribs are located above the web, and the end faces of the ribs are flush with the end faces of the die. The ribs of the rib plate 15 are 24mm high, 2mm thick, and the web is 2mm thick, with an overall length of 146mm and a width of 120mm.

[0051] The aluminum alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com