Steel drum W-shaped beading machine

A technology for rolling bars and steel drums, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of expanding the maximum outer diameter of steel drums and complicated structures, and achieve the reduction of the maximum outer diameter, reasonable structure, and convenient transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

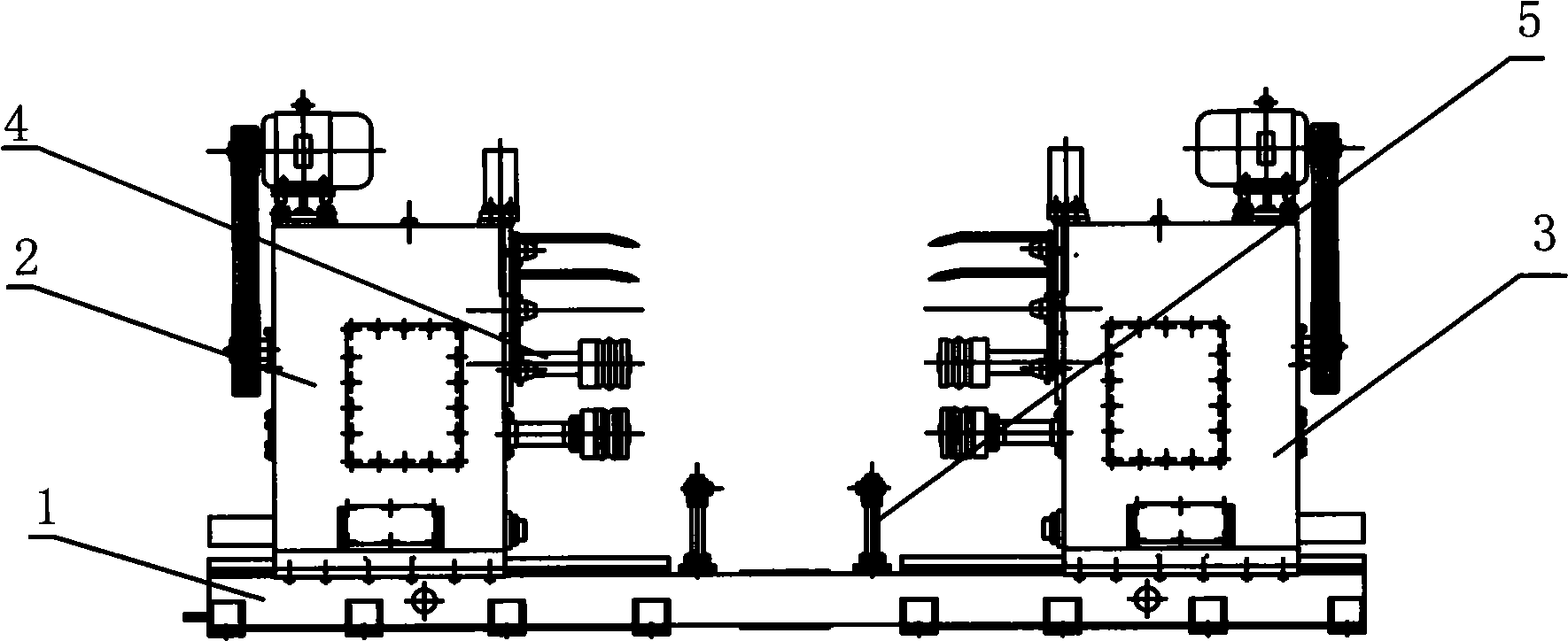

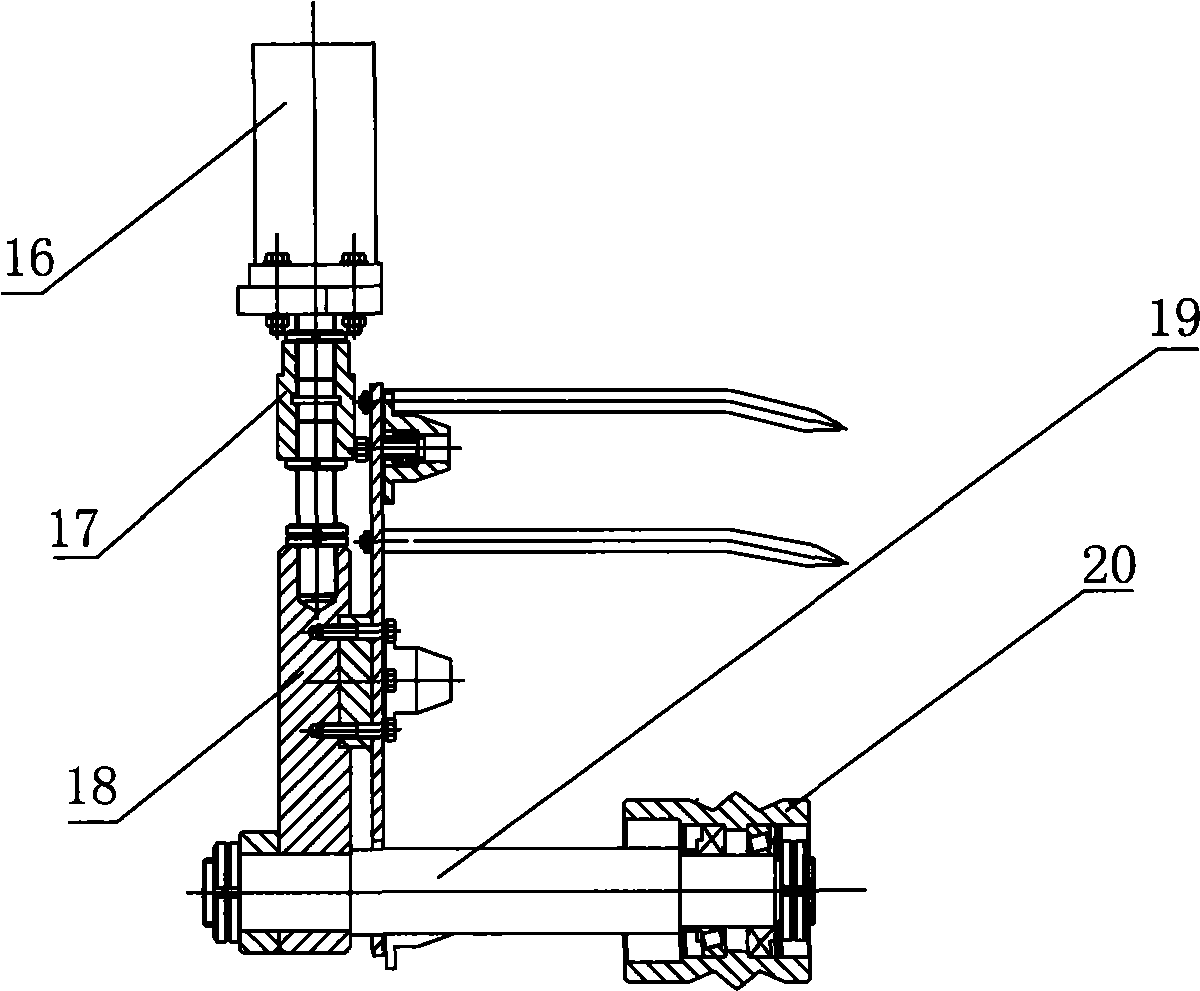

[0015] Such as figure 1 , 2 , 3 and 4, a steel barrel W-shaped rolling machine, including base 1, left box 2, right box 3, upper rolling mechanism 4, supporting mechanism 5, pneumatic system, hydraulic system and electrical system ;

[0016] A guide rail and a lower oil cylinder are installed on the base 1, and the base is made of steel plates and channel steels, which are mainly used for loading and bearing the sliding of the box;

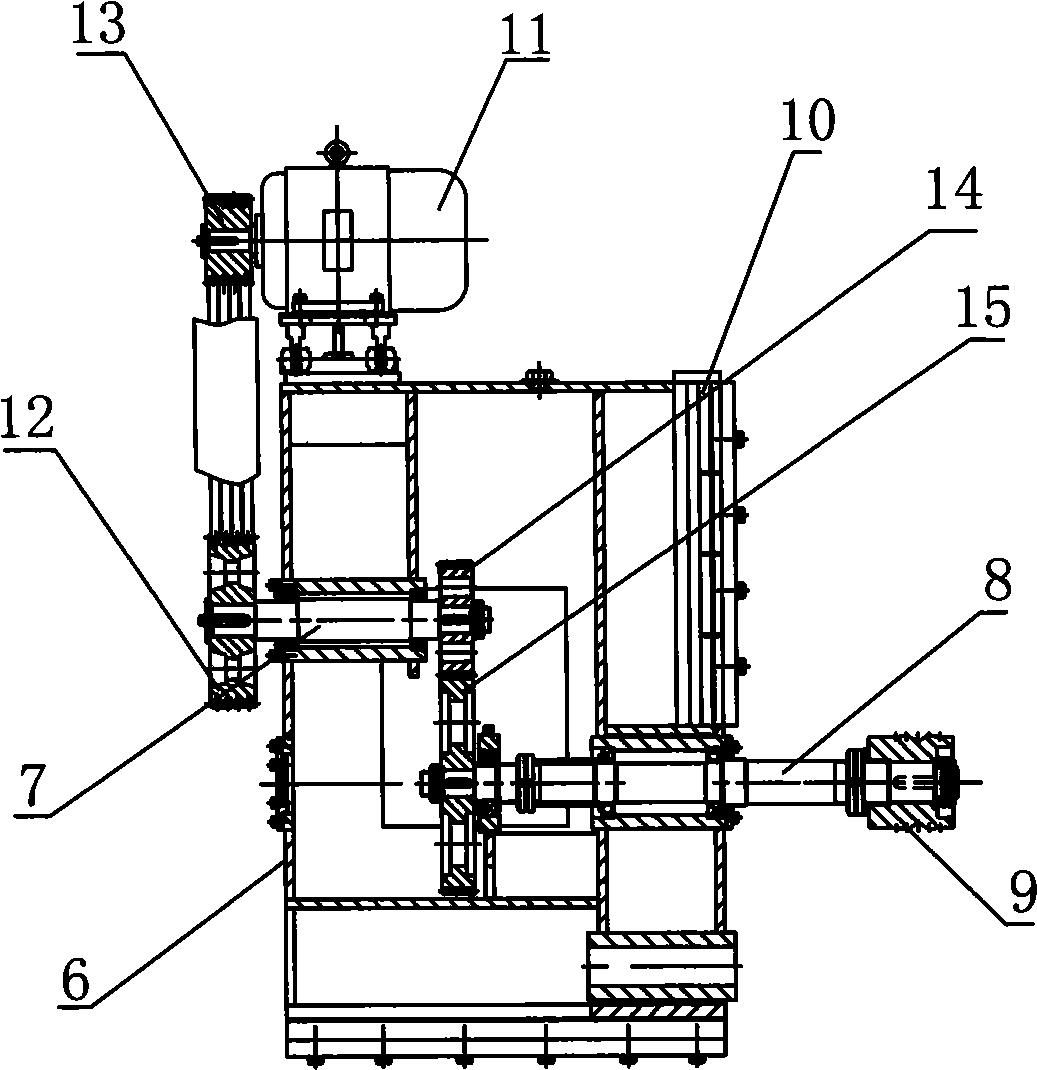

[0017] Described left case body 2 and right case body 3 comprise case body 6, input shaft 7, output shaft 8, lower pressure roller 9, slide seat 10 and motor 11, and one end of described input shaft 7 is connected with the said input shaft 7 through large pulley 12. The small pulley 13 of 11 on the motor is connected, the other end of the input shaft 7 is connected with the large gear 15 on the output shaft 8 through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com