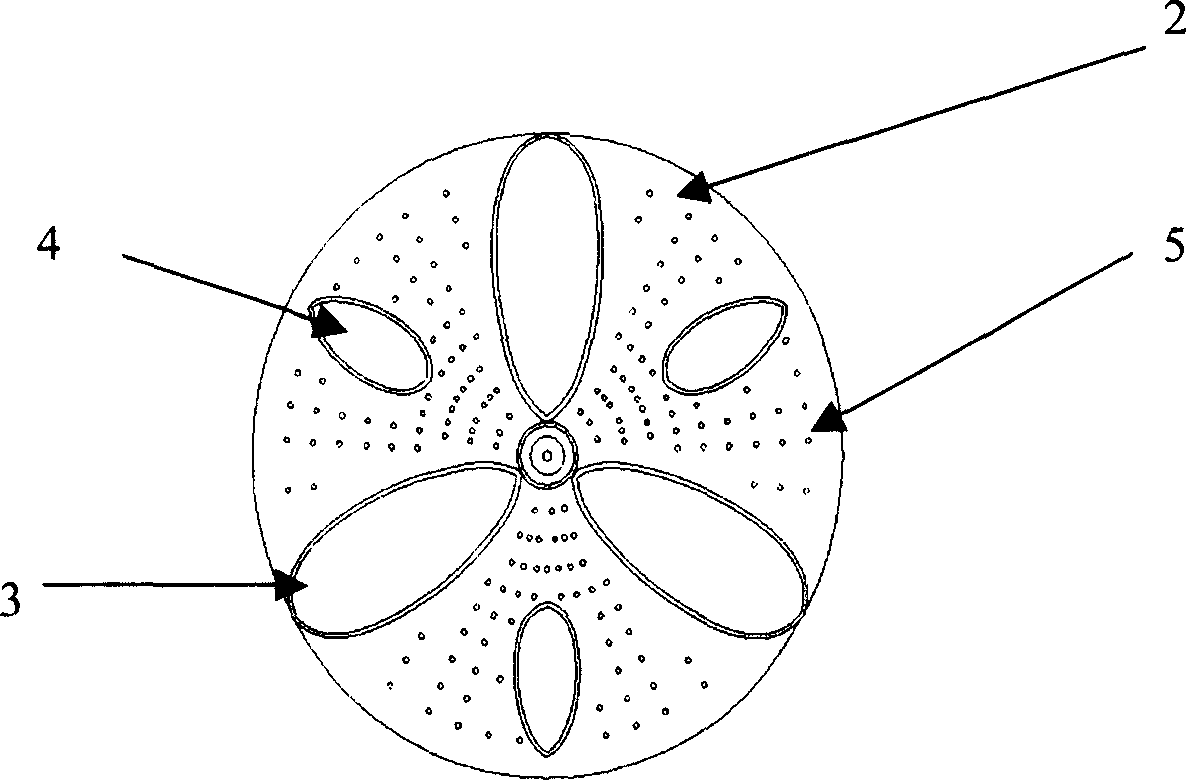

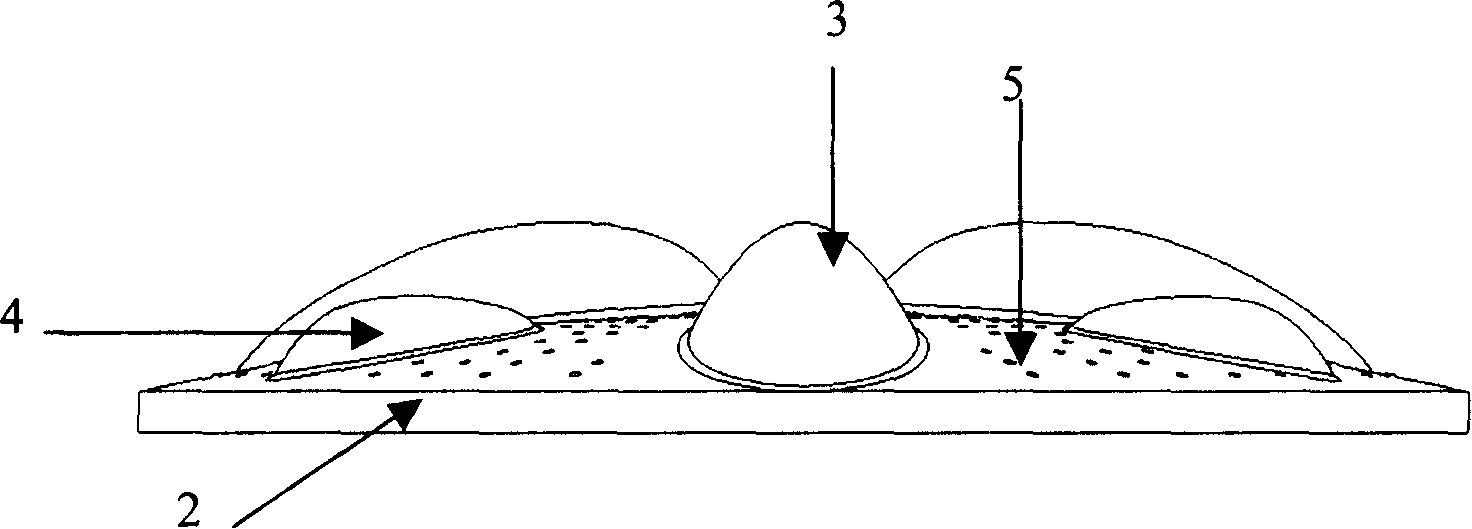

Modified washing machine impeller structure

A washing machine and pulsator technology, applied in the field of washing machines, can solve the problems of high entanglement rate of clothes, poor washing uniformity, affecting washing uniformity and entanglement rate, etc., and achieve the effect of increasing density, reducing entanglement, and improving the shape of the pulsator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0021] Put the clothes into the washing tub, start the program, the washing machine will automatically feed water to the specified water level, and then the pulsator 2 will act. The action ratio is, for example, 1.2:0.4. Compared with the prior art, "the on-off ratio of the general action is 1.8:0.6. During washing, the washing tub does not operate. Until the end of washing, the pulsator operates at a ratio of 0.4:1.0 to realize the loosening function of the clothes." Such a ratio It can better take into account the reduction of entanglement and the guarantee of cleanliness. (The opening and stopping ratio of the pulsator will increase the winding, so the opening and stopping ratio should be reduced as much as possible, but the low opening and stopping ratio will affect the cleanliness.) When the pulsator 2 moves, the three relatively large rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com