A method and device for measuring the height of the large rib of the inner ring of a tapered roller bearing

A technology of tapered roller bearing and large rib, applied in the direction of measuring devices, instruments, etc., to achieve the effect of improving measurement accuracy, increasing rotation flexibility and service life, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

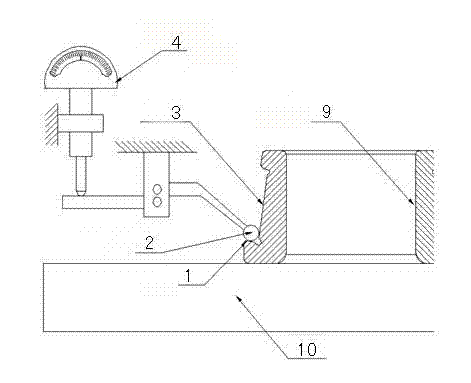

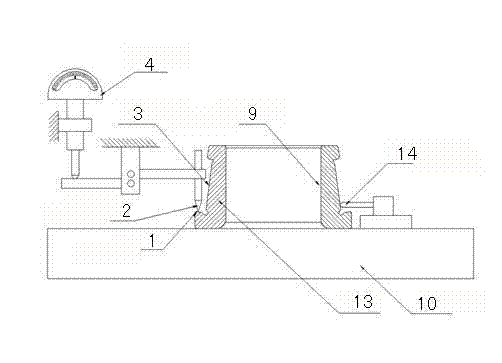

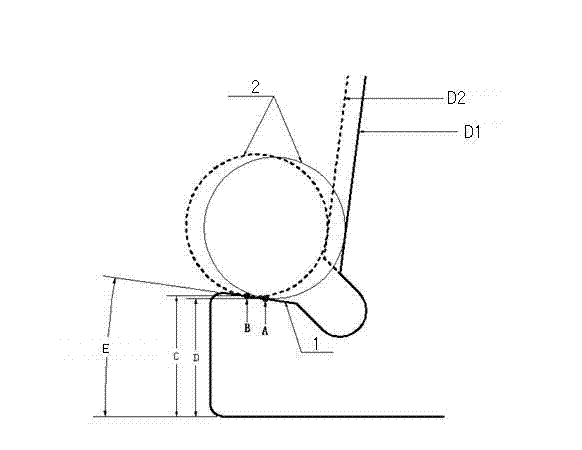

[0041] Such as Image 6 with Figure 7 As shown, the method for measuring the height of the large rib of the tapered roller bearing inner ring of the present invention includes:

[0042] (1) The height of the large rib of the inner ring of the tapered roller bearing is measured by center positioning. First, a positioning cone is provided. Using the matching characteristics of the positioning cone and the inner diameter of the inner ring of the tapered roller bearing to be tested, the tapered roller bearing to be tested is The inner ring is positioned on the platform, and a certain pressure is given to the positioning cone to ensure that the positioning cone is in full contact with the inner diameter circumference of the tapered roller bearing to be tested. The position of the center of the circle, and keep the relative position of the center of the circle and the probe of the measuring instrument unchanged. It is worth noting that this step is a common method for positioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| End diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com