Deburring equipment of hose surface of glass fiber machine and processing method thereof

A glass fiber and deburring technology, which is applied in fabric surface trimming, singeing, textiles and paper making, etc., can solve the problems of unsuitable glass fiber woven hose, high melting point of glass fiber, brittle fracture of glass fiber, etc., to achieve Improve electrical breakdown resistance, high production efficiency, and avoid brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

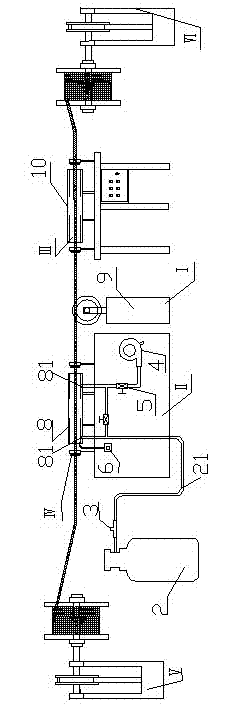

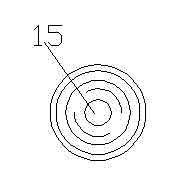

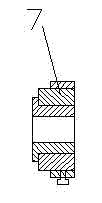

[0027] see Figure 1~Figure 5 , the present invention includes frame I, combustion device II, melting device III, hose expansion device IV, pay-off frame V and take-up frame VI, combustion device II, melting device III, hose expansion device IV, pay-off frame V Both take-up frame Ⅵ and take-up frame Ⅵ are set on machine base Ⅰ. According to the processing flow, the pay-off frame V, the combustion device II, the melting device III and the take-up frame VI are arranged in sequence, and the two ends of the inlet and outlet of the combustion device II and the inlet and outlet of the melting device III are respectively equipped with a hose expansion device IV. The heights of the combustion device II and the melting device III are the same, and the above four hose expansion devices IV are installed coaxially and match the heights of the combustion device II and the melting device III.

[0028] The combustion device II includes a combustion chamber 8, a liquefied gas cylinder 2, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com