Anti-sedimentation glass fiber reinforced plastic yacht

A glass fiber reinforced plastic and yacht technology, applied in the field of ships, can solve the problems of large draught of the hull, heavy bottom of the ship, and reduce the carrying capacity of the hull, and achieve the effects of less recycling, firm surface connection, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

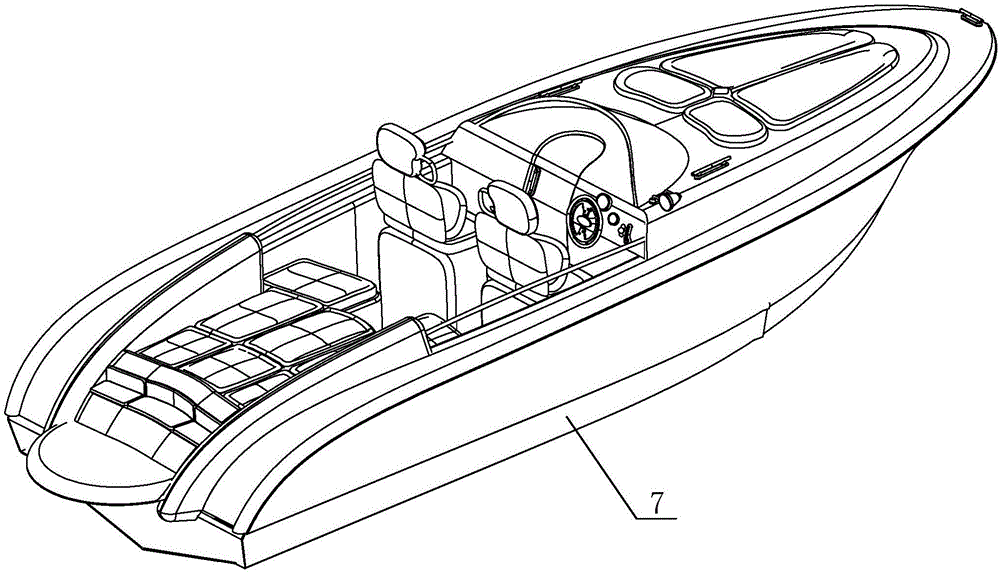

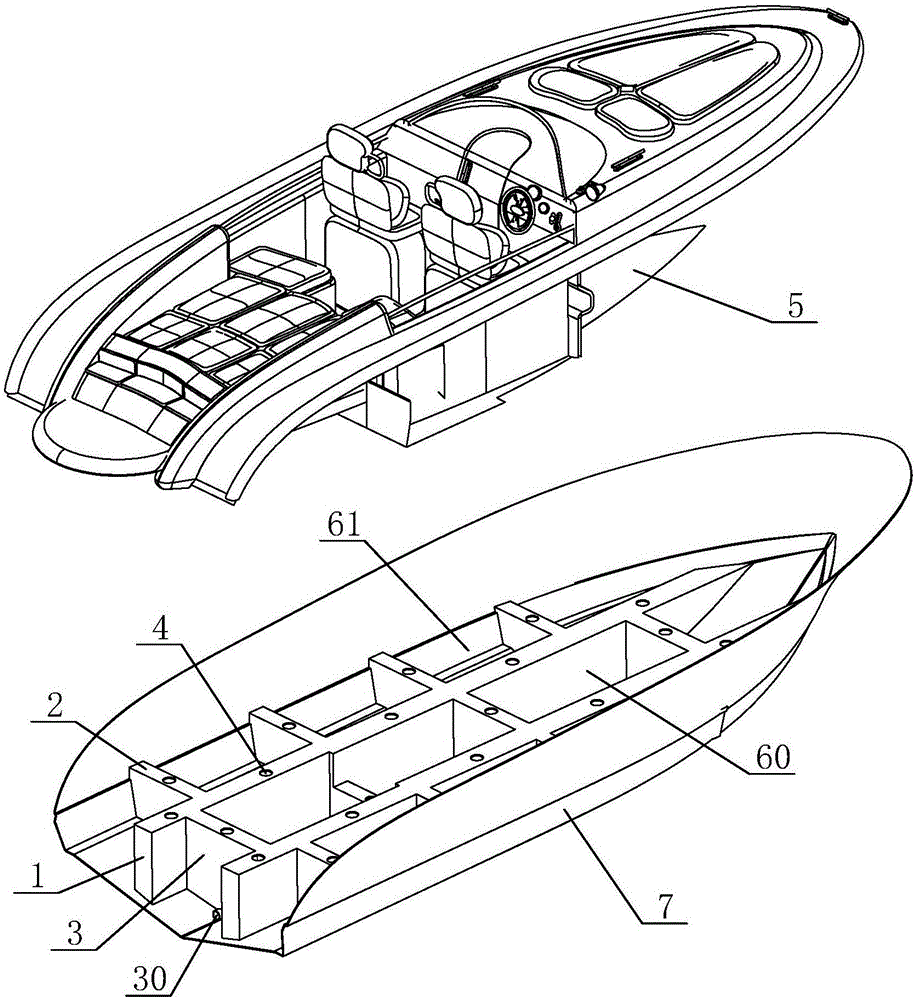

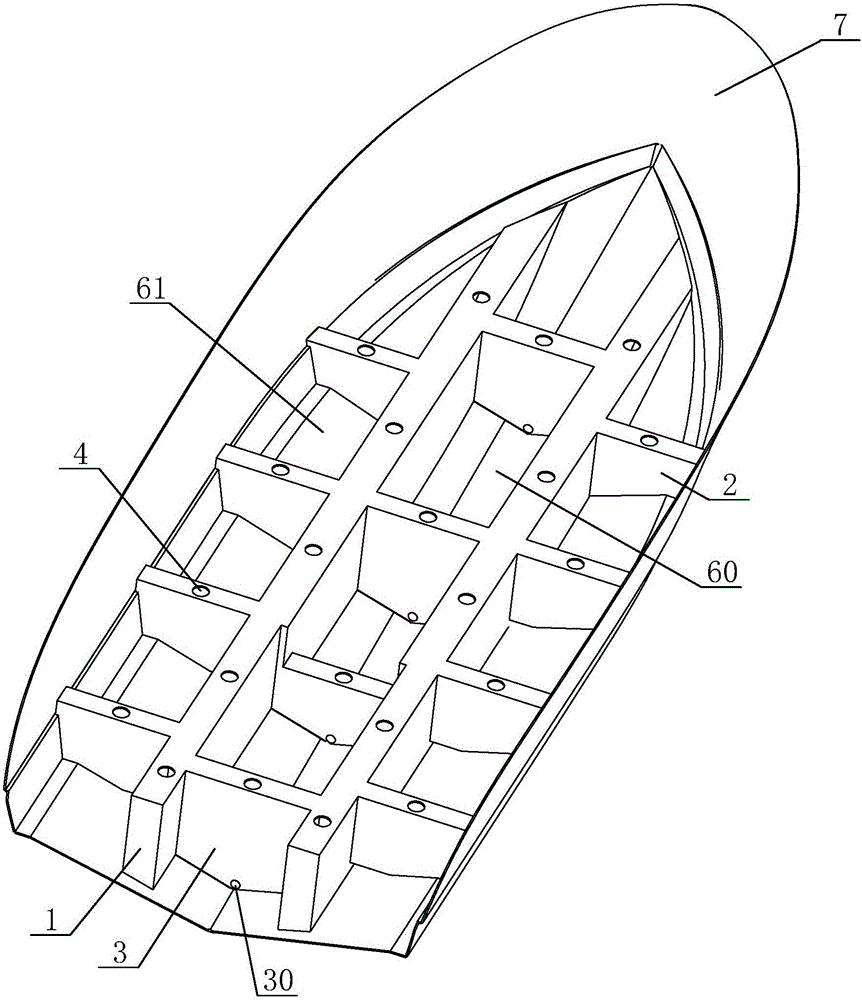

[0037] Such as figure 1 As shown, an anti-sinking fiberglass yacht includes a deck 5, a bottom and a keel structure, and is characterized in that: the keel structure includes several keels 1 and ribs 2, and the keels 1 and ribs 2 are arranged perpendicular to each other, and the keel 1 and the ribs 2. Integral molding is provided as a skeleton shell, the skeleton shell is made of a hydrophobic hard material, and a hollow cavity is provided inside the skeleton shell, and the cavity is filled with hard foamed plastic; the keel structure passes through Structural glue is glued to the inner surface of the bottom of the ship, the deck 5 is fixed above the keel structure, and the deck 5 and the bottom of the ship are fixed by fasteners; the keel 1, keel 2 and the inner side of the bottom of the ship are enclosed to form a side cavity 61. The side cavity 61 is filled with ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com