A kind of high-strength atmospheric corrosion-resistant steel bar and preparation method thereof

A technology of atmospheric corrosion resistance and steel bars, applied in furnaces, furnace types, hearth furnaces, etc., can solve the problems of cumbersome preparation process of high-strength atmospheric corrosion-resistant steel bars, waste of iron elements, high price, etc., and achieve strong practicability and market Competitiveness, production cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

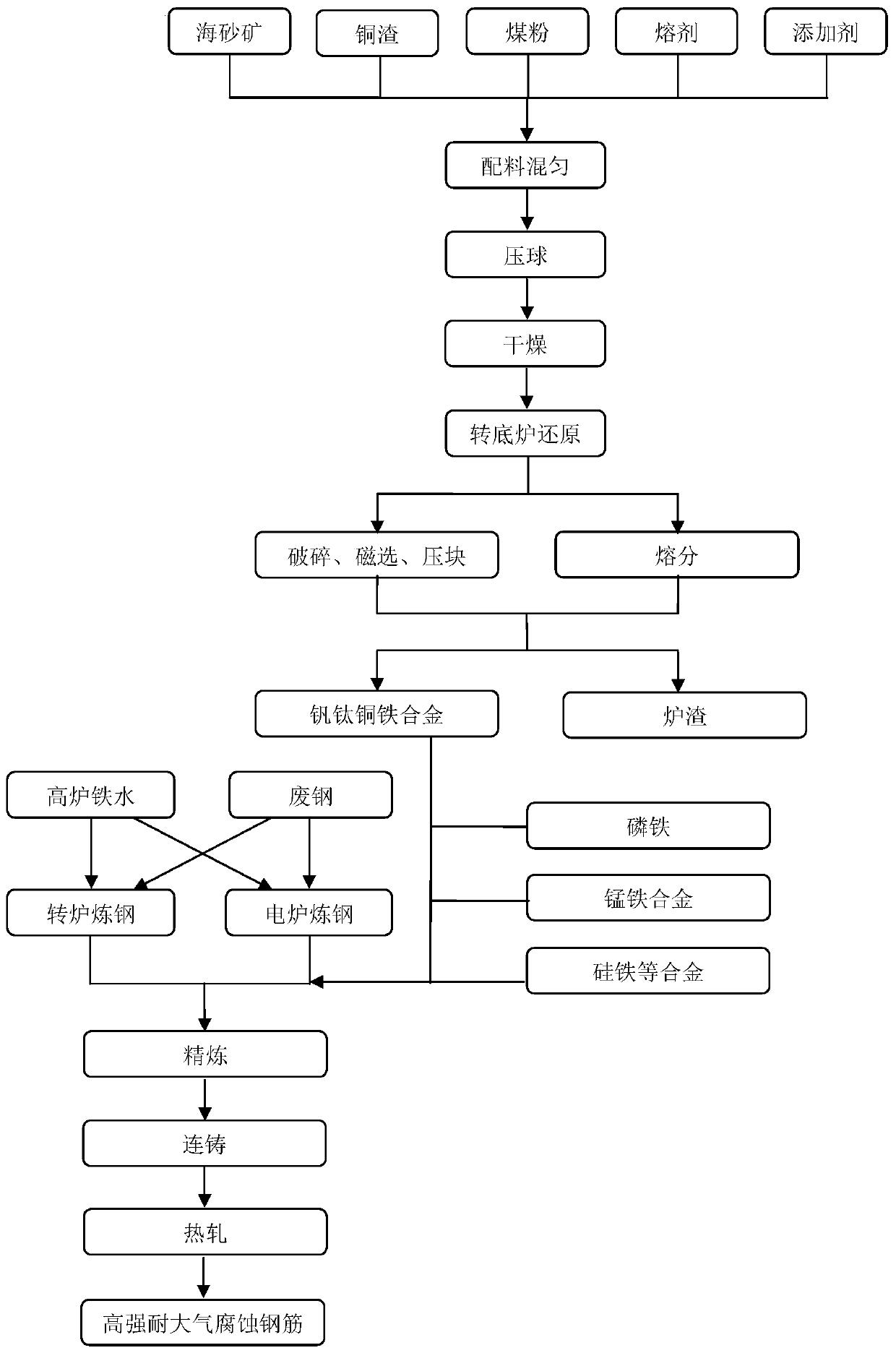

[0038] In a first aspect, the present invention provides a method for preparing high-strength atmospheric corrosion-resistant steel bars, such as figure 1 shown, including the following steps:

[0039]Step S1: Perform pretreatments such as drying, crushing, grinding and screening on the raw materials (sea placer, copper slag and coal powder), and mix the pretreated raw materials evenly to obtain a raw material mixture.

[0040] Specifically, in the above step S1, the pretreatment process may include the following steps: drying sea placer, copper slag and coal powder at 150°C to 200°C; drying the dried sea placer, copper slag and coal The powder is crushed to a particle size of 0.1 mm to 25 mm; the crushed sea placer, copper slag and coal powder are ground by a ball mill until the particle size is -120 mesh, accounting for more than 80%. After the above pretreatment, the moisture of the raw materials is basically removed, and the particle size becomes smaller at the same time,...

Embodiment 1

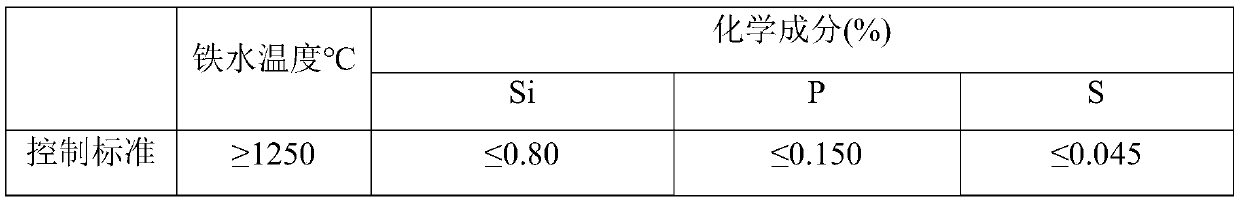

[0120] The main components of copper slag in this embodiment are shown in Table 1, and the components of sea placer, coal powder and slaked lime are shown in Table 2, Table 3 and Table 4, respectively.

[0121] The main component (wt%) of table 1 copper slag

[0122]

[0123] The main component (wt%) of table 2 sea placer

[0124]

[0125] The main component (wt%) of table 3 pulverized coal

[0126]

[0127] The main component (wt%) of table 4 slaked lime

[0128]

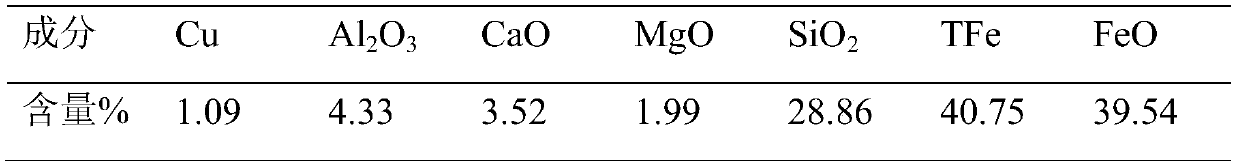

[0129] In this embodiment, the reduction-crushing-magnetic separation-briquetting process route is adopted, and the operation steps of producing vanadium-titanium-copper-iron alloy using the above-mentioned copper slag and sea sand ore are as follows:

[0130] Dry the copper slag, sea placer and coal powder at 150°C, crush them to a particle size of 0.1-25mm, and use a ball mill to grind the copper slag, sea placer and coal powder until the particles with a particle size of -120 mesh account for more ...

Embodiment 2

[0135] The components of copper slag, sea sand ore, coal powder and slaked lime in this embodiment refer to Table 1, Table 2, Table 3 and Table 4 in Embodiment 1, respectively.

[0136] In this embodiment, the reduction-crushing-magnetic separation-briquetting process route is adopted, and the operation steps of producing vanadium-titanium-copper-iron alloy using the above-mentioned copper slag and sea sand ore are as follows:

[0137] Dry the copper slag, sea placer and coal powder at 200°C, crush them to a particle size of 0.1-25 mm, and use a ball mill to grind the copper slag, sea placer and coal powder until the particle size is -120 mesh and account for more than 80%; weigh The ratio of copper slag, sea sand ore, coal powder, slaked lime and syrup is 145..4:100:51.70:38.73:26.86; Converted weighing to 0.7 (CaO / SiO 2=0.7), the additive syrup is weighed by 7% of the total weight of copper slag powder, sea sand ore powder, coal powder, and slaked lime, and water is weighed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com