Non-magnetic stainless steel for medical apparatuses and instruments and manufacturing method of non-magnetic stainless steel

A technology of non-magnetic stainless steel and medical equipment, which is applied in the field of high-hardness, high-toughness antibacterial non-magnetic stainless steel and its manufacture, can solve biological sensitivity and other problems, and achieve the effect of avoiding infection and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

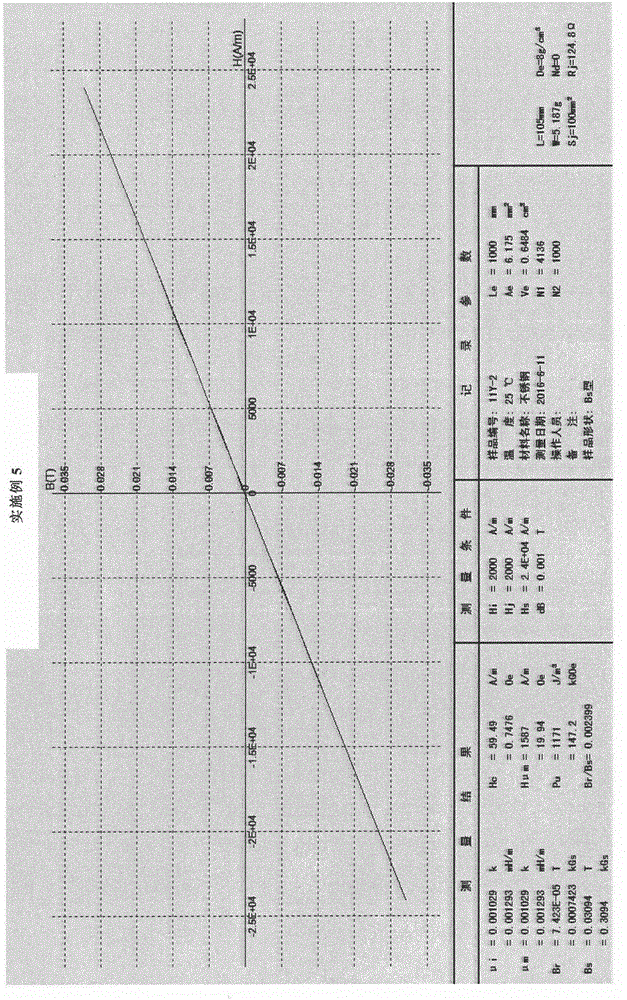

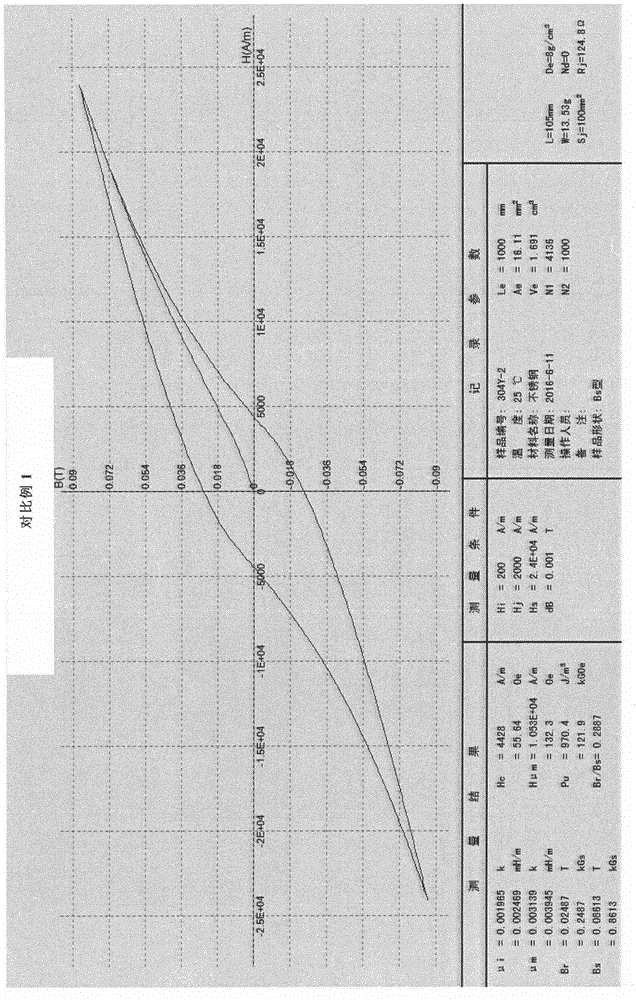

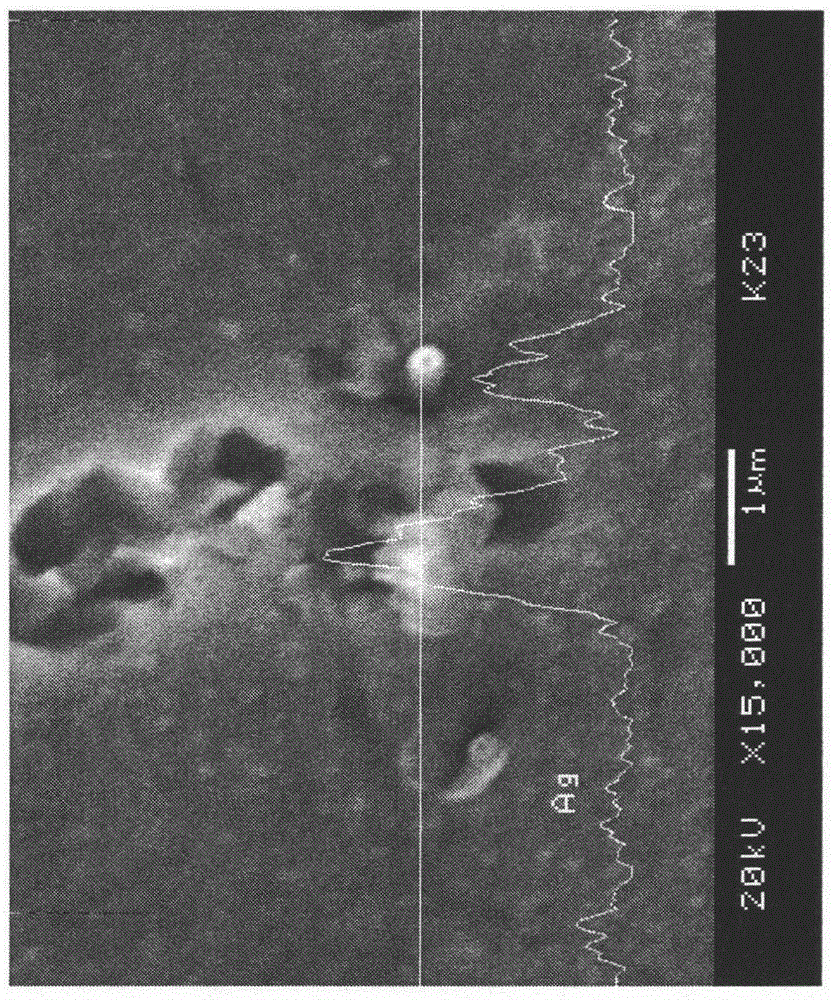

[0047] Table 1 is the composition of the steel of the embodiment of the present invention and the comparative example, and Table 2 is the key process parameters and properties of the steel of the embodiment of the present invention and the comparative example. Comparative example 1 is the most commonly used austenitic stainless steel SUS 304. Comparative example 2 is the steel type disclosed in the invention patent application 201010231859.5. Comparative example 3 is the steel type disclosed in the invention patent application 201210050809.6. Comparative Example 4 is a typical martensitic stainless steel 30Cr13 for medical equipment.

[0048] The embodiment of the present invention takes the production process of electric furnace-AOD smelting as an example: put ferrochromium, ferronickel and scrap steel into the electric furnace for melting, after mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com