Flexible positive electrode of lithium-ion battery, preparation method of flexible positive electrode and super-flexible lithium-ion all-battery

A lithium-ion battery and positive electrode technology, applied in the field of inorganic functional material preparation, can solve the problems affecting the electrochemical performance and mechanical performance of the battery, reduce the utilization rate of active materials, etc., and achieve the effects of avoiding brittle fracture, promoting development, and single control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

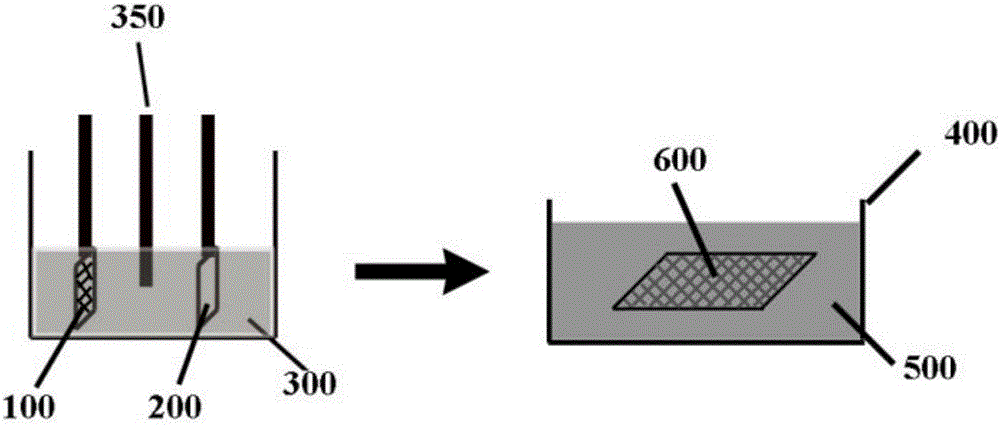

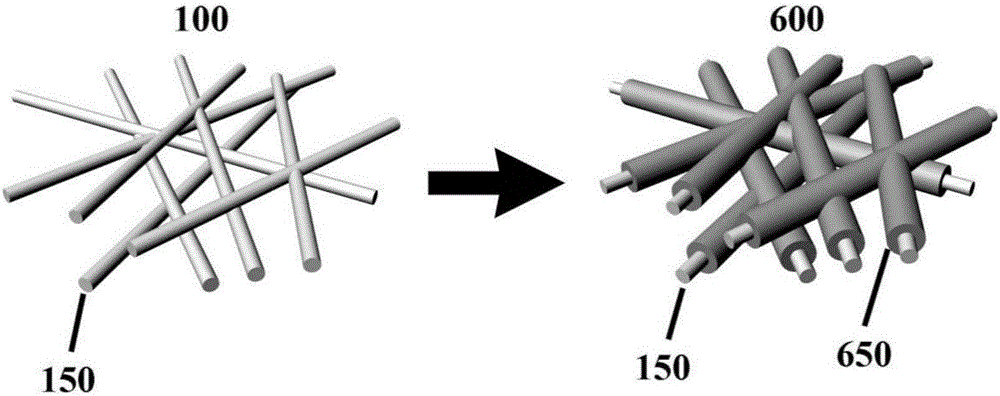

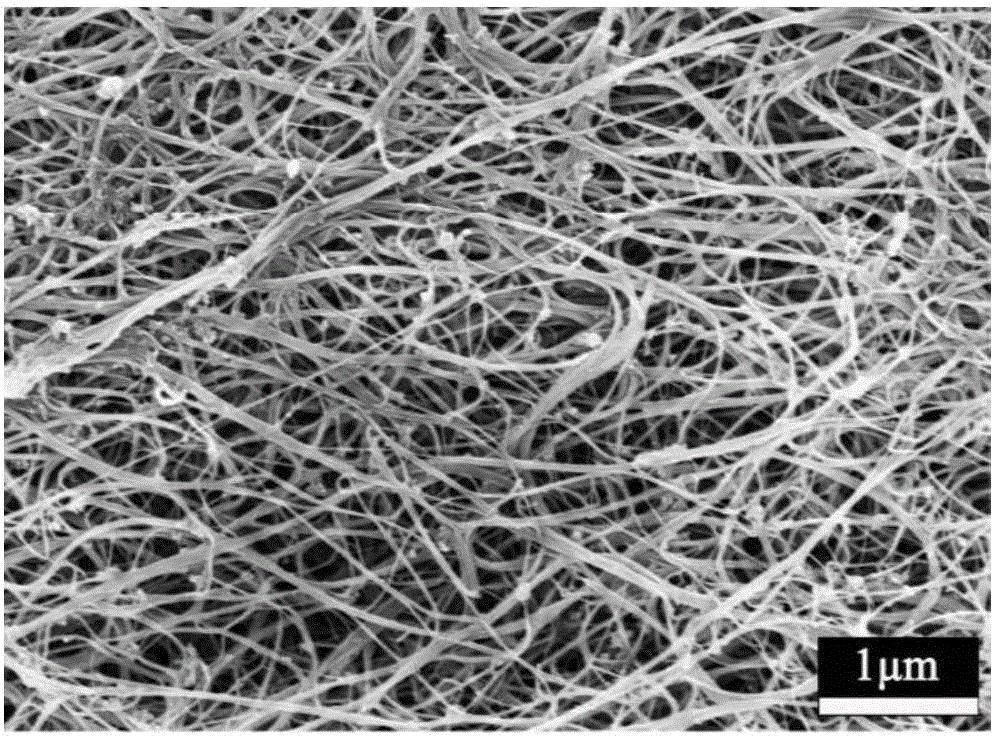

[0051] Sample preparation: The commercially obtained flexible carbon nanotube film (the original carbon nanotube scanning electron microscope image is shown in image 3 shown) placed in a tube furnace, heated to 1000°C under the protection of argon, with a heating rate of 10°C / min, and kept for 2 hours to remove organic impurities on the surface of carbon nanotubes. Measure 4mL of concentrated hydrochloric acid and 50mL of deionized water, mix and stir, and prepare 1mol / L dilute hydrochloric acid for later use. Metal Ni sheet (1×2cm 2 ) and carbon nanotube paper (1×1cm 2 ) were soaked in dilute hydrochloric acid and acetone for 15 minutes, then taken out, rinsed with deionized water, and dried in an oven at 50°C for later use.

[0052] 1) Electroplating precursor

[0053] Prepare an aqueous solution with a concentration of 0.01M manganese sulfate, 0.1M sodium sulfate and 0.1M sodium acetate as the electroplating solution (300). The carbon nanotube film is used as the workin...

Embodiment 2

[0064] The preparation of the sample in the ultra-flexible Li-ion of this example is similar to Example 1. First, place the carbon nanotube film in a tube furnace and heat it to 1000°C to remove the organic matter on the surface, then soak the metal Ni sheet and the treated carbon nanotube paper in dilute hydrochloric acid and acetone respectively, and use deionized Wash it with water and place it in an oven at 70°C to dry it for later use.

[0065] 1) Preparation of electroplating precursor

[0066] Prepare an aqueous solution with a concentration of 3 M manganese sulfate, 0.1 M sodium sulfate and 0.1 M sodium acetate as the electroplating solution. The carbon nanotube film is used as the working electrode (100) and the metal nickel sheet is used as the counter electrode (200) for electrochemical deposition, and a constant voltage is applied to the working electrode for electrochemical deposition. The voltage can be between 0.75 and 1.4 V. The deposition The typical time is...

Embodiment 3

[0075] The preparation of the sample in the ultra-flexible lithium ion of this embodiment is similar to that of Examples 1 and 2. First, place the carbon nanotube film in a tube furnace and heat it to 1000°C to remove the organic matter on the surface, then soak the metal Ni sheet and the treated carbon nanotube paper in dilute hydrochloric acid and acetone respectively, and use deionized Wash it with water and place it in an oven at 70°C to dry it for later use.

[0076] 1) Preparation of electroplating precursor

[0077] Prepare an aqueous solution with a concentration of 1 M manganese sulfate, 1 M sodium sulfate and 1 M sodium acetate as the electroplating solution.

[0078] Electrochemical deposition is performed by using the carbon nanotube film as the working electrode (100), the metal nickel sheet as the counter electrode (200), and the silver / silver chloride as the reference electrode (350). Apply a current density of 6.5 mA / cm on the working electrode (100) 2 Elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com