Intermediate temperature solid oxide fuel cell cathode material with perovskite structure and preparation method thereof

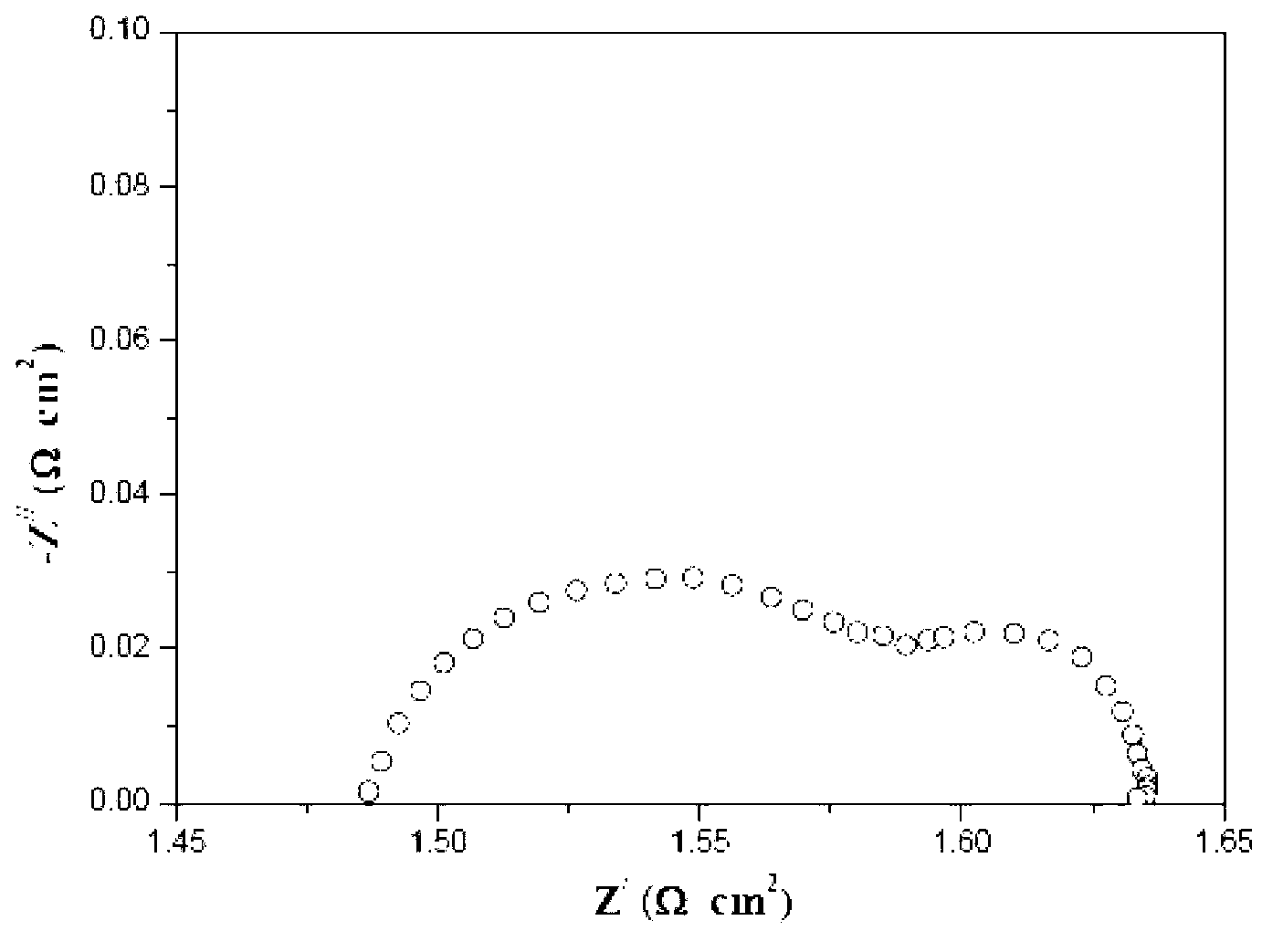

A fuel cell cathode and solid oxide technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of difficult to meet the requirements of cathode materials, high mixed conductivity, low polarization overpotential, etc., and achieve good chemical stability , good thermal stability and close thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

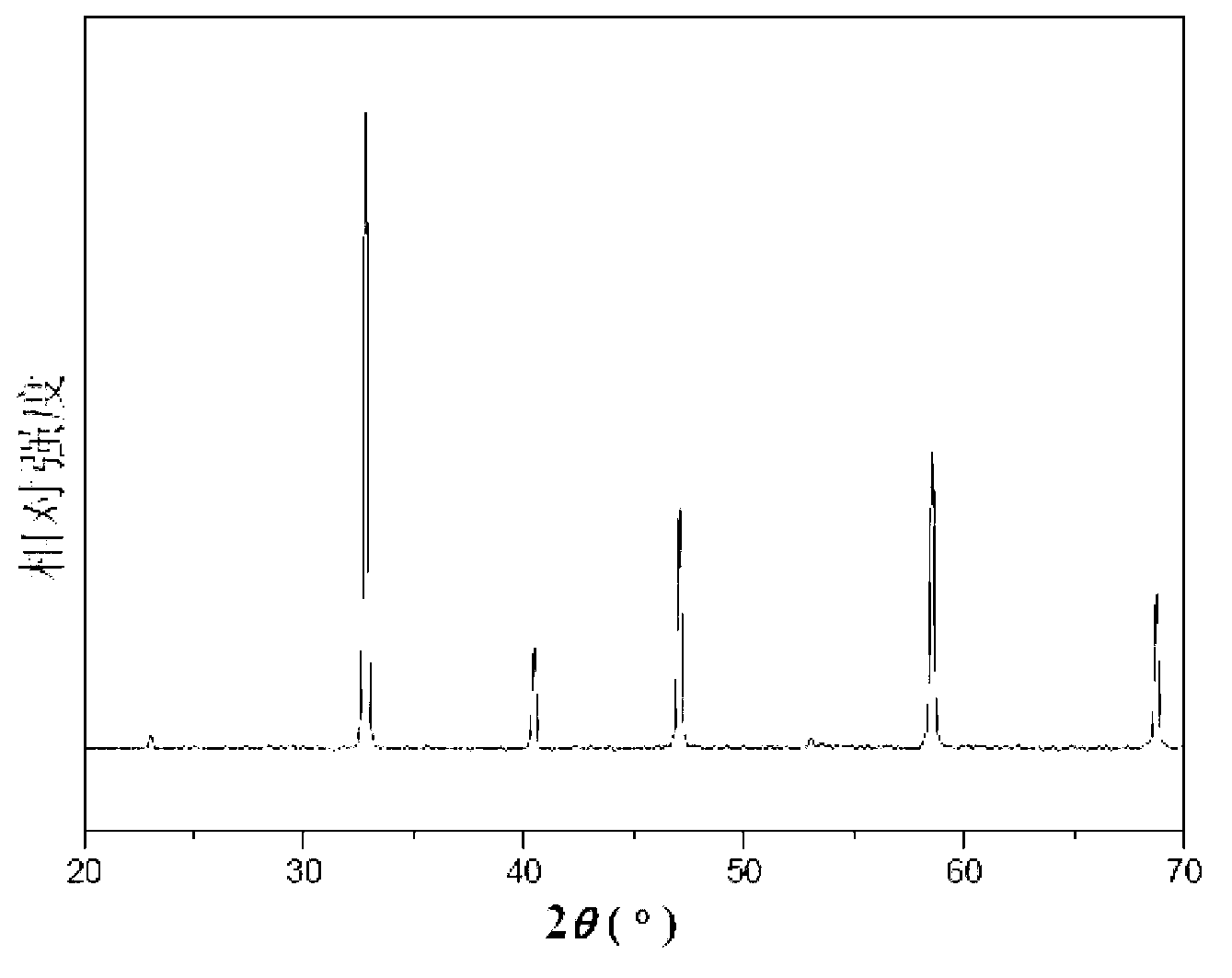

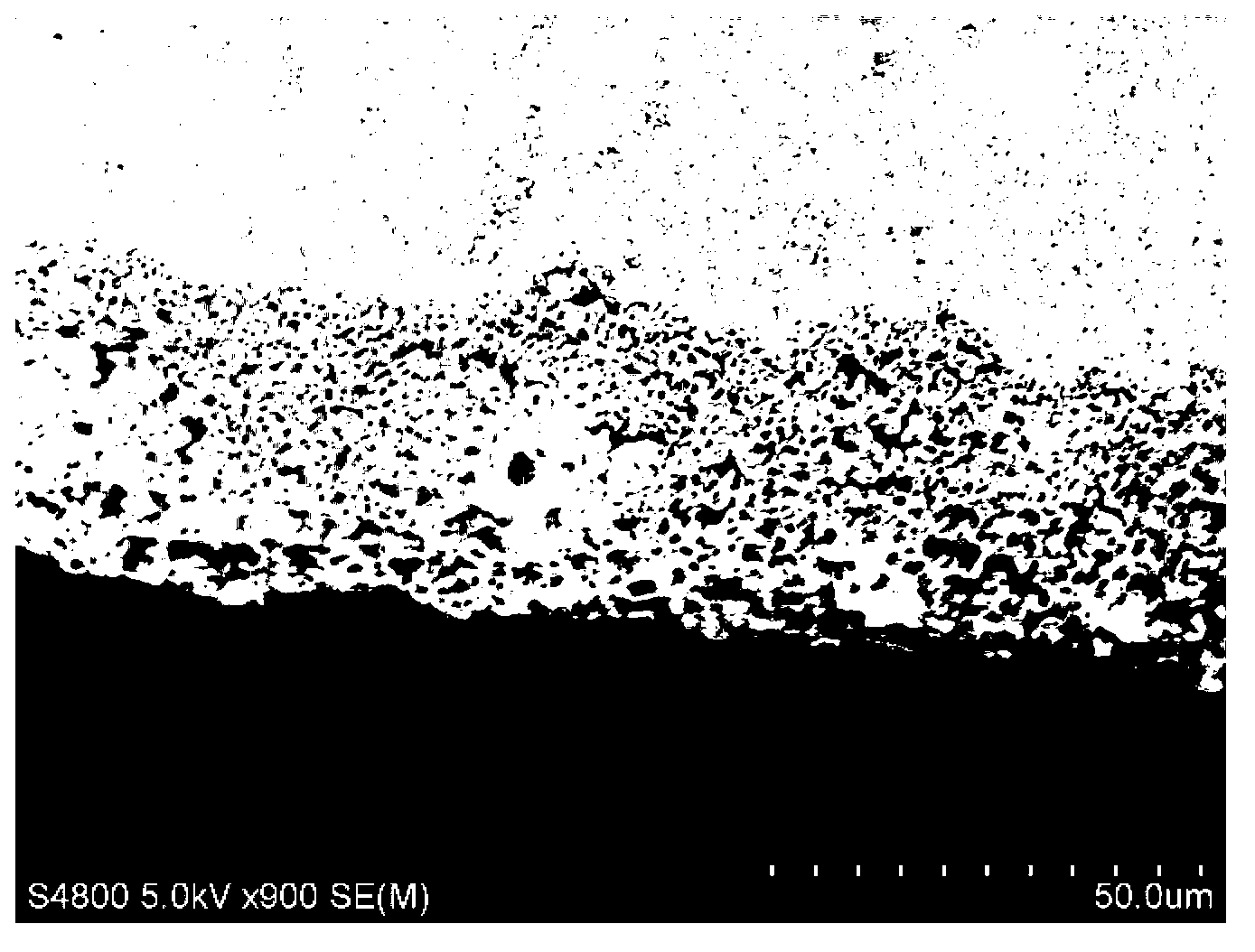

[0019] Specific implementation mode 1: The cathode material of the intermediate temperature solid oxide fuel cell with a perovskite structure according to this embodiment is characterized in that the general composition formula of the cathode material for an intermediate temperature solid oxide fuel cell with a perovskite structure is AFe 1-x m x o 3 ; Wherein, A is Ca, Sr or Ba, M is Cu, Co or Ni, 0.1<x<1.0.

specific Embodiment approach 2

[0020] Specific embodiment 2: The method for preparing the cathode material of the intermediate temperature solid oxide fuel cell with the perovskite structure in this embodiment is characterized in that the preparation method of the cathode material for the intermediate temperature solid oxide fuel cell with the perovskite structure is carried out in the following steps:

[0021] 1. According to the chemical formula AFe 1-x m x o 3 , according to the stoichiometric ratio, weigh the carbonate of analytically pure element A and the analytically pure Fe 2 o 3 And analytically pure nitrate of element M; wherein, A is Ca, Sr or Ba, M is Cu, Co or Ni, 0.1<x<1.0;

[0022] Two, the carbonate and Fe of element A weighed in step one 2 o 3 Added to HNO with a concentration of 1mol / L 3 , so that the carbonate of element A and Fe 2 o 3 Completely dissolve, then add the nitrate of the element M weighed in step 1, stir evenly to obtain a nitrate solution;

[0023] 3. The molar rati...

specific Embodiment approach 3

[0026] Specific embodiment 3: The difference between this embodiment and specific embodiment 2 is that in step 3, the molar ratio of total metal ions in the nitrate solution to glycine is 1:2, and glycine is weighed. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com