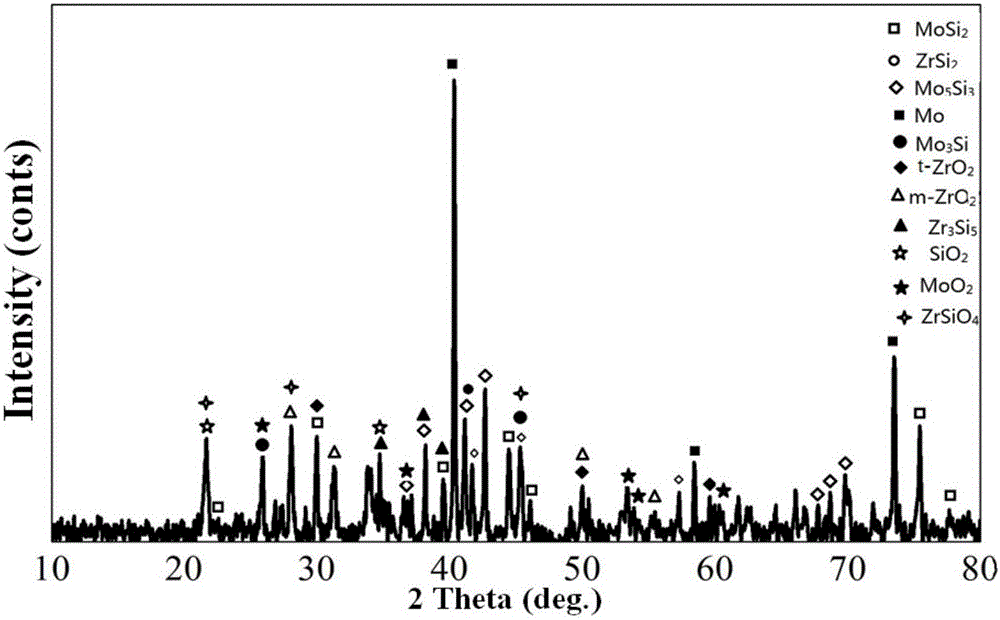

Molybdenum-alloy MoSi2-ZrO2-Y2O3 coating, preparation method therefor and application of molybdenum-alloy MoSi2-ZrO2-Y2O3 coating

A mosi2-zro2-y2o3, molybdenum alloy technology, applied in the field of ultra-high temperature anti-oxidation coating preparation, can solve the problems of reduced Si element concentration, cracks, poor anti-oxidation performance, etc., to achieve good thermal matching, low evaporation rate, The effect of reducing the oxygen diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Pretreatment of molybdenum alloy substrate: Molybdenum alloy substrate is polished with sandpaper until the surface is smooth and flat, then pickling and alkali cleaning are performed, and the acid composition is HCl: HNO 3 :H 2 O=1:3:16 (volume fraction), the lye composition is NaOH solution with a pH value of 11, then ultrasonically cleaned in alcohol, and then put into a drying box for drying.

[0054] (2) Slurry preparation: MoSi with a particle size of 0.6 μm 2 Powder, ZrO with a particle size of 200nm 2 Powder and Y with a particle size of 100nm 2 o 3 Powder by mass percentage MoSi 2 60%, ZrO 230%, Y 2 o 3 9%, 1% of additives (including Si0.5%, SiC 0.5%, particle size 1μm) (the purity of the above substances is not less than 99.7%), put them into a ball mill jar, and the PVB mass percentage is 0.2%. The ethanol solution was used as a dispersant, the cemented carbide ball was used as a grinding ball, and the slurry was obtained by wet ball milling for...

Embodiment 2

[0059] (1) Pretreatment of molybdenum alloy substrate: Molybdenum alloy substrate is polished with sandpaper until the surface is smooth and flat, then pickling and alkali cleaning are performed, and the acid composition is HCl: HNO 3 :H 2 O=1:3:16 (volume fraction), the lye composition is a NaOH solution with a pH value of 12, and then ultrasonically cleaned in alcohol, then put into a drying box for drying.

[0060] (2) Slurry preparation: MoSi with a particle size of 1.2 μm 2 Powder, ZrO with a particle size of 240nm 2 Powder and Y with a particle size of 150nm 2 o 3 Powder by mass percentage MoSi 2 77%, ZrO 2 10%, Y 2 o 3 10%, 3% additives (including Si 2%, SiC 1%, particle size 0.1μm) (the purity of the above substances is not less than 99.6%), put it into a ball mill jar, and the PVB mass percentage is 0.2% Ethanol solution was used as dispersant, cemented carbide balls were used as grinding balls, and wet ball milled for 12 hours to obtain slurry; the amount ...

Embodiment 3

[0065] (1) Pretreatment of molybdenum alloy substrate: Molybdenum alloy substrate is polished with sandpaper until the surface is smooth and flat, then pickling and alkali cleaning are performed, and the acid composition is HCl: HNO 3 :H 2 O=1:3:16 (volume fraction), the lye composition is NaOH solution with a pH value of 13, then ultrasonically cleaned in alcohol, and then put into a drying box for drying.

[0066] (2) Slurry preparation: MoSi with a particle size of 2 μm 2 Powder, ZrO with a particle size of 300nm 2 Powder and Y with a particle size of 200nm 2 o 3 Powder by mass percentage MoSi 2 80%, ZrO 2 13%, Y 2 o 3 5%, 2% additives (including Si 1.5%, SiC 0.5%, particle size 0.5μm) (the purity of the above substances is not less than 99.5%), put it into a ball mill jar, and the PVB mass percentage is 0.2% The ethanol solution is used as a dispersant, the cemented carbide ball is used as a grinding ball, and the slurry is obtained by wet ball milling for 15 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com