Cathode material for proton conductor SOFC (solid oxide fuel cell) and preparation method

A solid oxide, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor stability, low cathode oxygen vacancy solubility, low temperature cathode polarization, etc. Catalytic activity, effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

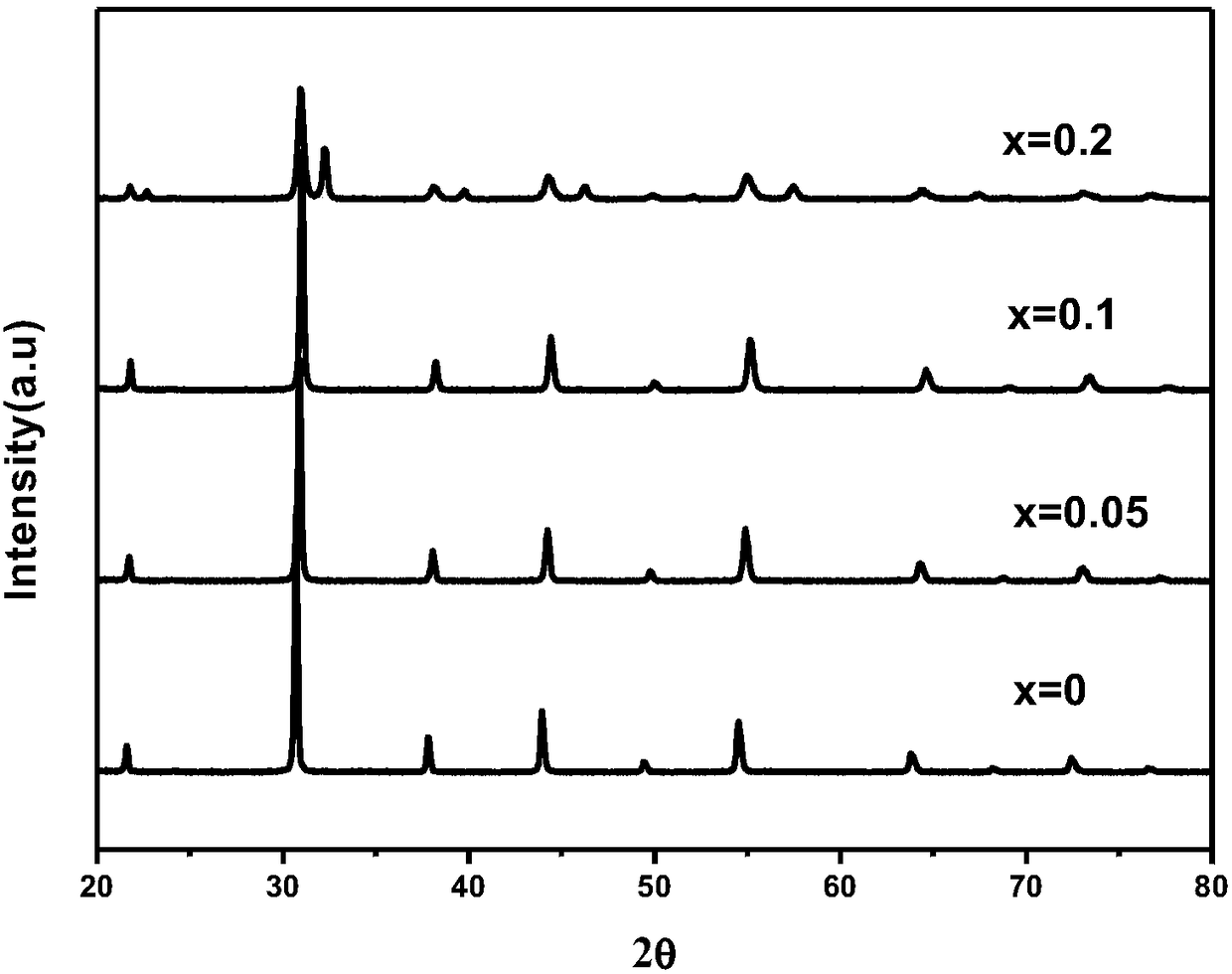

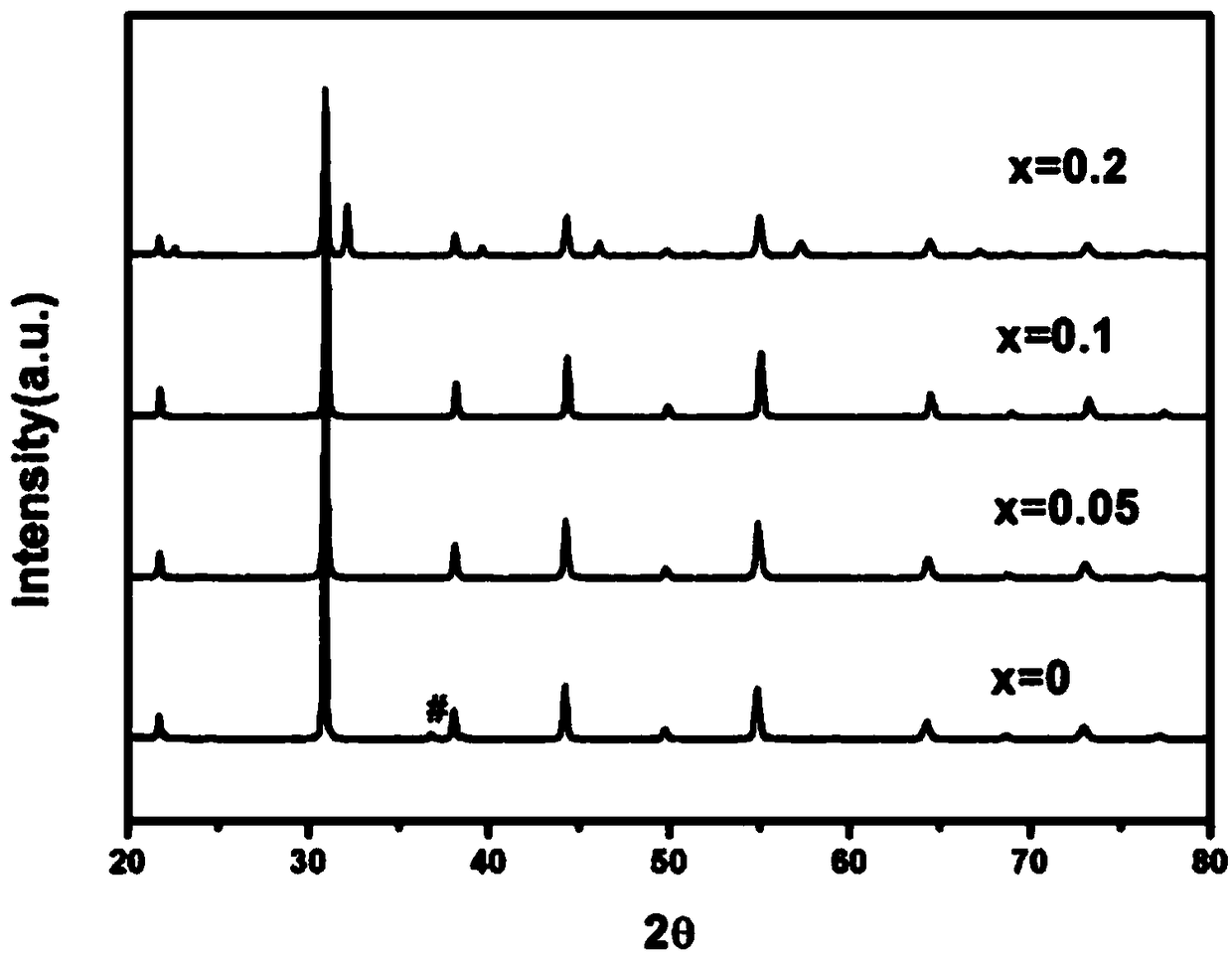

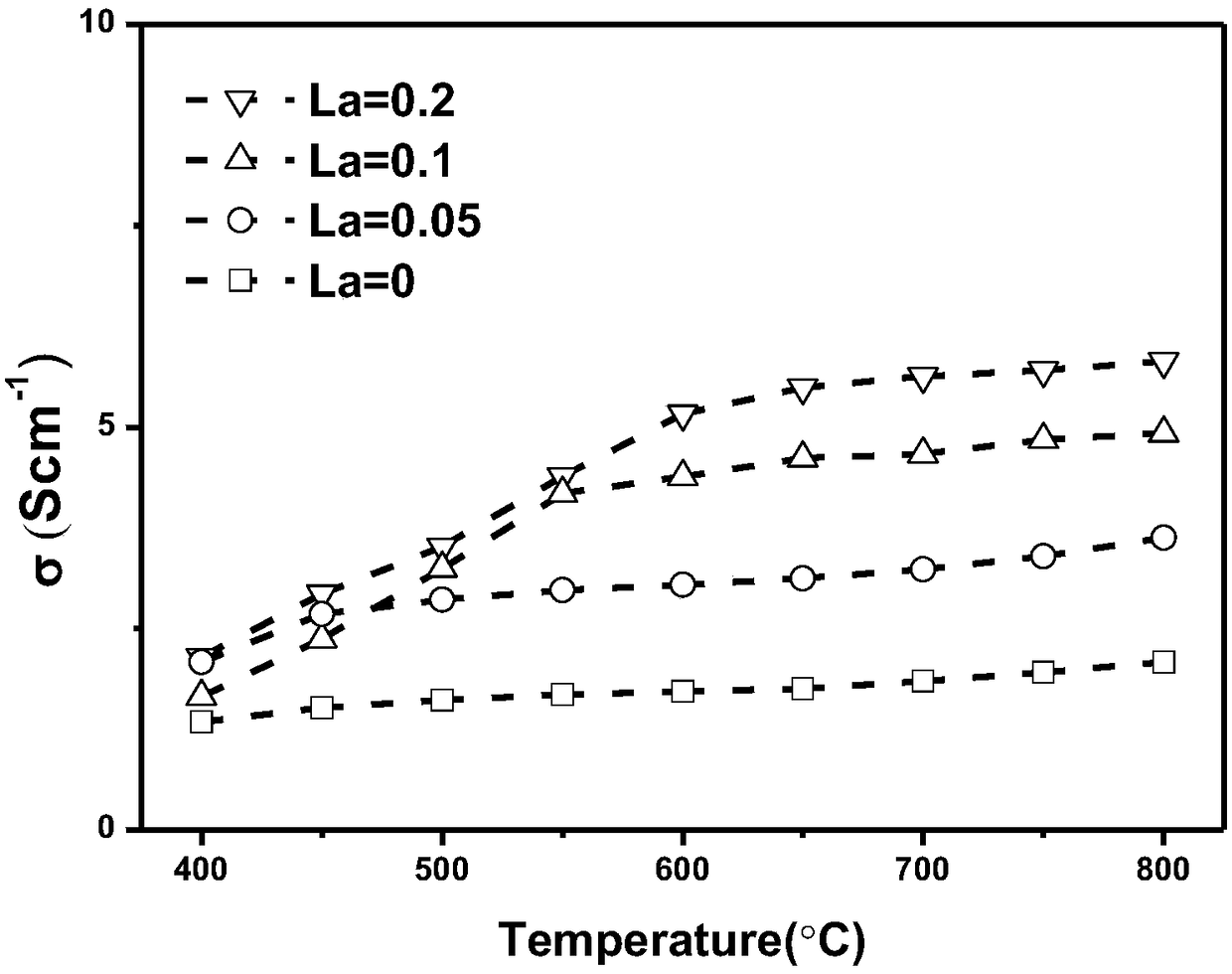

[0024] The preparation method of the single-phase cathode material: the present invention adopts the improved citric acid combustion method to make powder, according to the mole of Ba:La:Co:Fe:Zr:Y=1-x:x:0.4:0.4:0.1:0.1 Proportionally weigh the chemical raw materials corresponding to each element, add citric acid and EDTA two complexing agents, dissolve with nitric acid and ammonia water, adjust PH≈7, burn primary powder, and then pre-fire at 1000°C-3h to prepare the cathode Powder Ba 1-x La x Fe 0.4 co 0.4 Zr 0.1 Y 0.1 , where x=0, 0.05, 0.1, 0.2.

[0025] The concrete steps of preparation method are:

[0026] (1) First, find the corresponding chemicals in proportion to the elements in the cathode material formula, and calculate C according to the molar mass of each element 4 h 6 BaO 4 , Zr(NO 3 ) 4 ·3H 2 O, Fe(NO 3 ) 3 9H 2 O, Y (NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, La(NO 3 ) 3 ·6H 2 The quality of O required raw material; Described formula is Ba 1...

Embodiment 1

[0030] Example 1: Ba 1-x La x Fe 0.4 co 0.4 Zr 0.1 Y 0.1 o 3-δ When the cathode is x=0, the mass of the required raw material is calculated according to the molar mass of each element. After the calculation is completed, the oxide zirconide Zr(NO 3 ) 4 ·3H 2 O in a clean beaker, add 50-100ml of distilled water, add 10-20ml of nitric acid, heat, stir until the solution is clear; then weigh C 4 h 6 BaO 4 , Y(NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Co(NO 3 ) 2 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O complexing agents citric acid and ethylenediaminetetraacetic acid (EDTA), all added to the 3 ) 4 After clarifying the beaker of the solution, add an appropriate amount of ammonia water to adjust the PH value, and stir until the solution is clear. At this time, the pH ≈ 7, and the solution to be fired is prepared; put the prepared solution to be fired into an alumina ceramic pot, heat and stir until the solution becomes It is viscous and undergoes a violent self-combustion r...

Embodiment 2

[0031] Example 2: Ba 1-x La x Fe 0.4 co 0.4 Zr 0.1 Y 0.1 o 3-δ When the cathode is x=0.05, calculate the mass of the raw material required when x=0.05 according to the molar mass of each element. After the calculation is completed, other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com