C/SiC composite material, oxidation resistant coating for C/SiC composite material and preparation method thereof

An anti-oxidation coating and composite material technology, applied in the field of composite materials, can solve the problems of general high-temperature anti-oxidation effect of the coating, low bonding strength between the coating and the substrate, and high cost, and achieve easy industrial implementation, excellent anti-oxidation performance, The effect of enhancing antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Specific embodiments of the present invention will be described in detail below. In the following description, for the purpose of explanation and not limitation, specific details are set forth to help a more comprehensive understanding of the present invention. However, it should be understood by those skilled in the art that the present invention may also be practiced in other embodiments that do not include these specific details. It should be noted here that the claimed scope of the present invention is not limited to the following embodiments.

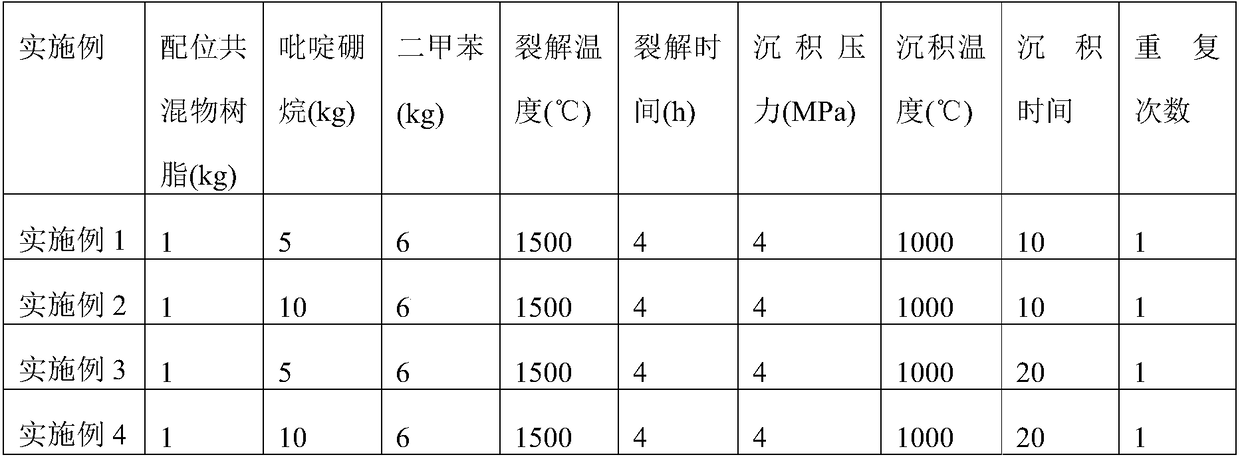

Embodiment 1

[0042] In this embodiment, an anti-oxidation coating for C / SiC composite material is prepared, and the specific process is as follows:

[0043] (1) Mechanically stir 1kg of the hafnium coordination blend resin prepared in the preparation example, 5kg of pyridineborane and 6kg of xylene for 5 hours, and then stand for 10 hours to prepare HfB 2 Ceramic precursor solution (viscosity 124.2mPa.s, solid content 45.3% by mass), and then brush the precursor solution onto the surface of a uniform and dense C / SiC composite matrix;

[0044] (2) Put the composite material in (1) in a curing tank, pressurize it to 2MPa, heat up to 200°C for 3 hours, and 350°C for 3 hours to make HfB 2 The ceramic precursor is fully cross-linked and solidified, and then placed in a cracking furnace under an argon atmosphere and cracked at 1500°C for 4 hours;

[0045] (3) Place the composite material in (2) in a deposition furnace, and pass in trichloromethylsilane under the conditions of 4KPa absolute pressure and ...

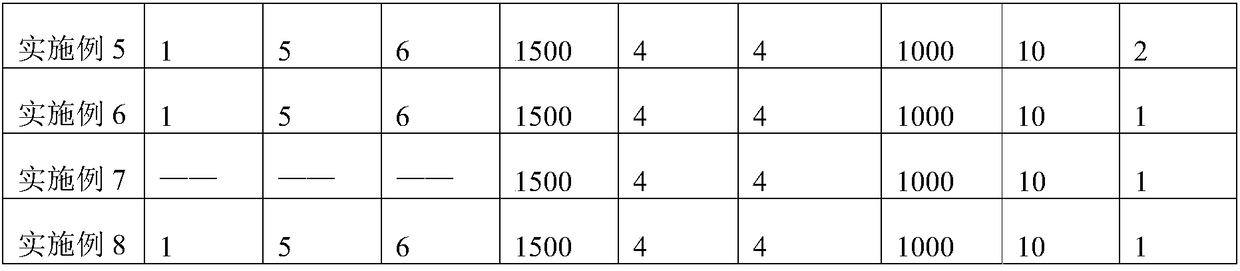

Embodiment 2

[0049] In this embodiment, another anti-oxidation coating of C / SiC composite material is prepared, and the specific process is as follows:

[0050] (1) Mechanically stir 1kg of the hafnium coordination blend resin prepared in the preparation example, 10kg of pyridineborane and 6kg of xylene for 5 hours, and after standing for 10 hours, prepare HfB 2 Ceramic precursor solution, and then brush the precursor solution onto the surface of the uniform and dense C / SiC composite matrix;

[0051] (2) Put the composite material in (1) in a curing tank, pressurize it to 2MPa, heat up to 200°C for 3 hours, and 350°C for 3 hours to make HfB 2 The ceramic precursor is fully cross-linked and solidified, and then placed in a cracking furnace under an argon atmosphere and cracked at 1500°C for 4 hours;

[0052] (3) Place the composite material in (2) in a deposition furnace, and pass in trichloromethylsilane under the conditions of 4KPa absolute pressure and 1000°C for a deposition time of 10 hours;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com