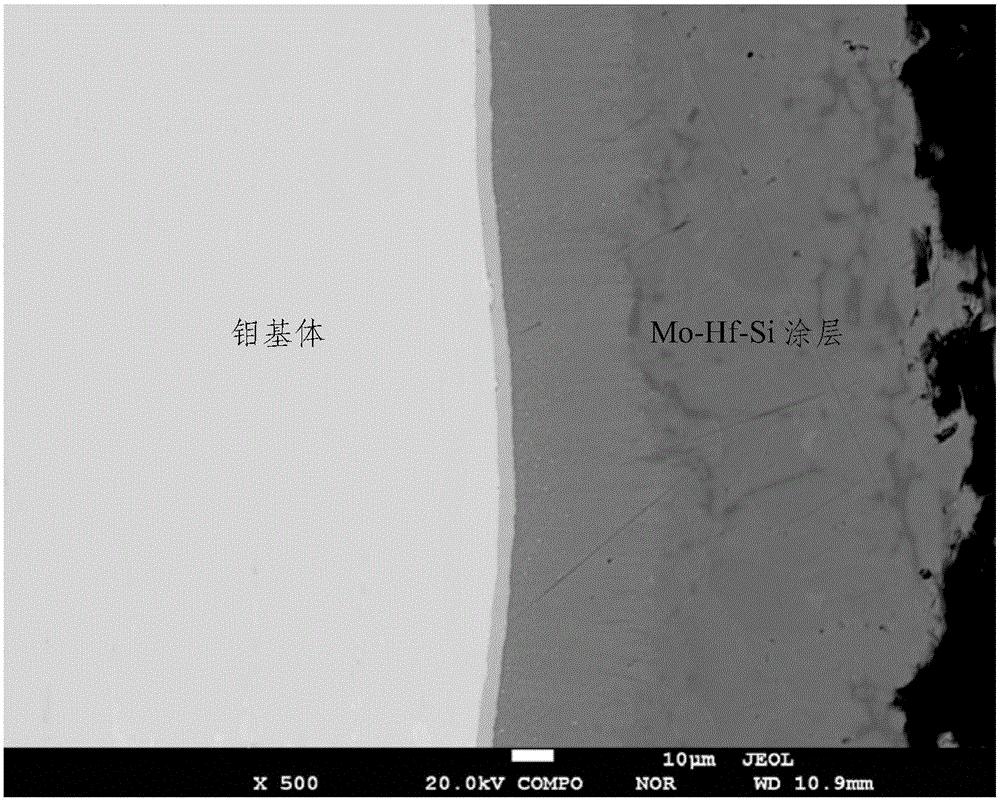

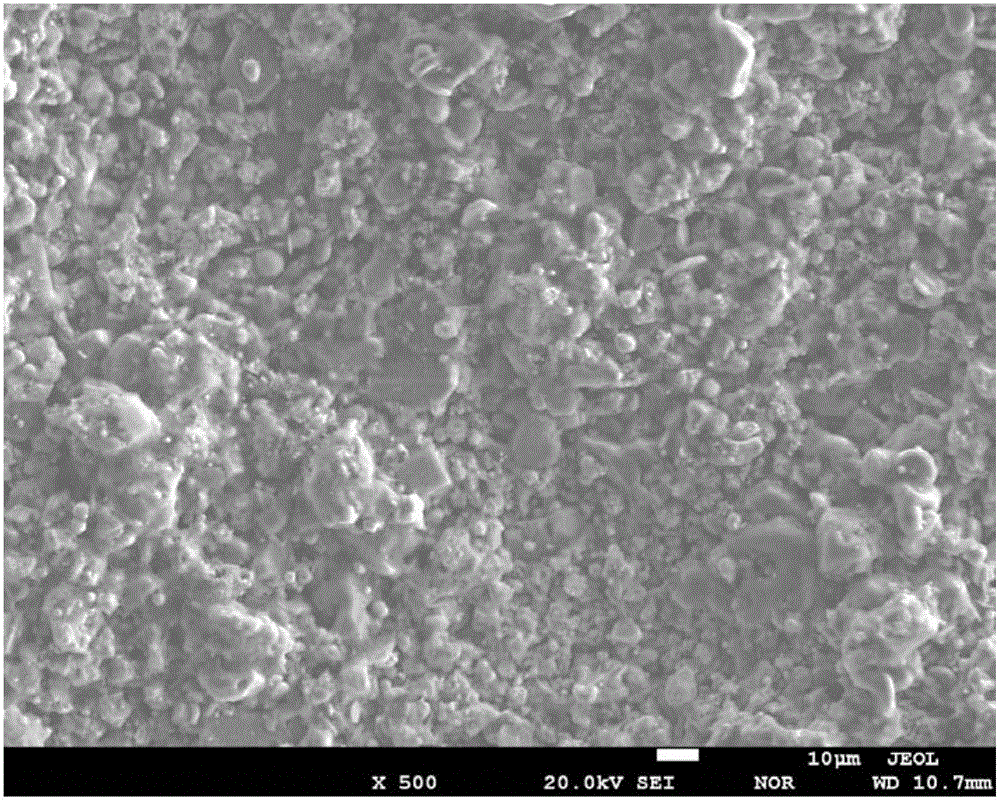

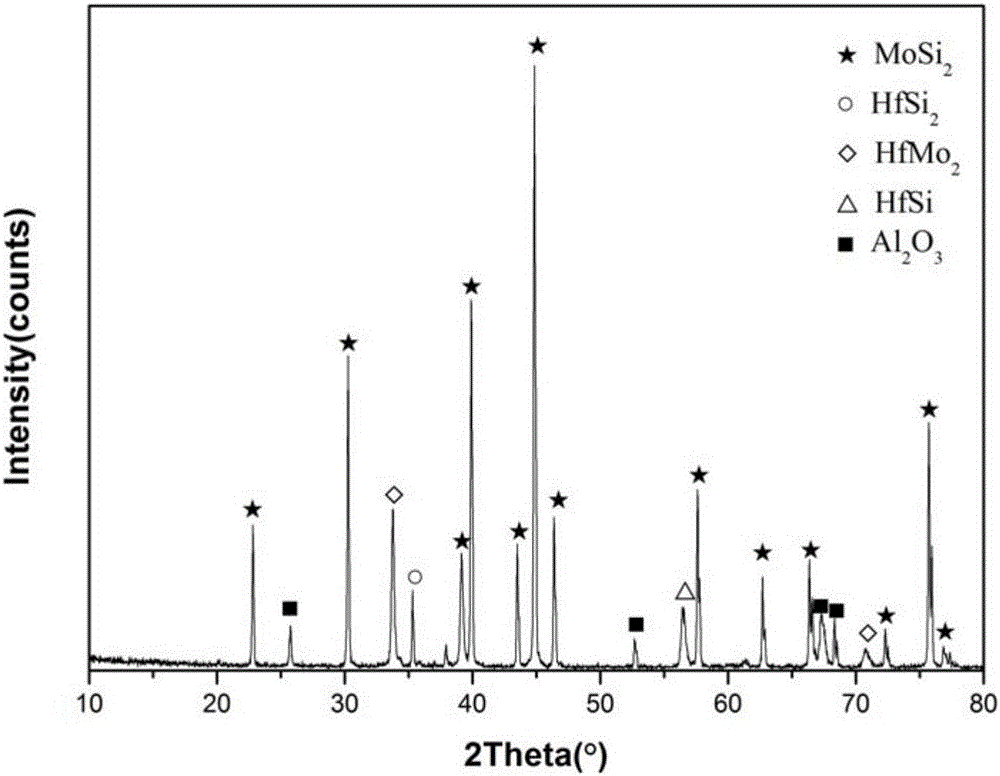

Molybdenum alloy high-temperature anti-oxidation Mo-Hf-Si coating and preparation method thereof

A high-temperature anti-oxidation, molybdenum alloy technology, applied in metal material coating process, coating, heating inorganic powder coating and other directions, to achieve excellent high-temperature oxidation resistance, uniform and dense coating structure, low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Molybdenum alloy substrate pretreatment: TZM molybdenum alloy (0.50wt% Ti, 0.08wt% Zr, 0.02wt% C, the balance is Mo) the substrate is polished with sandpaper until the surface is smooth and flat, then pickling and alkali Washing treatment, the acid composition is HCl: HNO 3 :H 2 O=1:3:16 (volume fraction), the lye composition is NaOH solution with a pH value of 11, then ultrasonically cleaned in alcohol, and then put into a drying box for drying.

[0060] (2) Slurry preparation: Mo powder and Hf powder with a particle size of 1 μm and Si powder and Al powder with a particle size of 0.5 μm 2 o 3 Powder and Y 2 o 3 The powder is composed of the following molar ratios: Mo 17%, Hf 9%, Si 69%, additives (Al 2 o 3 : Y 2 o 3 =7:1 molar ratio) 5% is put into the ball mill jar, with absolute ethanol as the ball milling medium (the ratio of the ball milling medium to the total mass of the powder is 2:1), add 0.1wt% binder PVB (polyvinyl alcohol Butyral), using Ar gas...

Embodiment 2

[0065] (1) Molybdenum alloy substrate pretreatment: TZM molybdenum alloy (0.50wt% Ti, 0.08wt% Zr, 0.02wt% C, the balance is Mo) the substrate is polished with sandpaper until the surface is smooth and flat, then pickling and alkali Washing treatment, the acid composition is HCl: HNO 3 :H 2 O=1:3:16 (volume fraction), the lye composition is a NaOH solution with a pH value of 13, then ultrasonically cleaned in alcohol, and put into a drying oven for drying.

[0066] (2) Slurry preparation: Mo powder and Hf powder with a particle size of 1 μm and Si powder and Al powder with a particle size of 0.1 μm 2 o 3 Powder and Y 2 o 3 The powder is composed of the following molar ratios: Mo 24%, Hf 8%, Si 65%, additives (Al 2 o 3 : Y 2 o 3 ==4:1 molar ratio) 3% into the ball milling tank, with distilled water as the ball milling medium (the ratio of the ball milling medium to the total mass of the powder is 1:1), adding 0.5wt% of the binder CMC (carboxymethyl Cellulose) was ball m...

Embodiment 3

[0071] (1) Molybdenum alloy substrate pretreatment: TZM molybdenum alloy (0.50wt% Ti, 0.08wt% Zr, 0.02wt% C, the balance is Mo) the substrate is polished with sandpaper until the surface is smooth and flat, then pickling and alkali Washing treatment, the acid composition is HCl: HNO 3 :H 2 O=1:3:16 (volume fraction), the lye composition is a NaOH solution with a pH value of 12, and then ultrasonically cleaned in alcohol, then put into a drying box for drying.

[0072] (2) Slurry preparation: Mo powder and Hf powder with a particle size of 3 μm and Si powder and Al powder with a particle size of 0.5 μm 2 o 3 Powder and Y 2 o 3 The powder is composed of the following molar ratios: Mo 21%, Hf 9%, Si 67%, additives (Al 2 o 3 : Y 2 o 3 ==5:1 molar ratio) 3% into the ball milling tank, with absolute ethanol as the ball milling medium (the ratio of the ball milling medium to the total mass of the powder is 3:1), adding 0.2wt% of the binder PVB (poly Vinyl butyral) was ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com