Motor drive device

A motor-driven, multi-phase motor technology, used in electrical devices, output power conversion devices, electric vehicles, etc., can solve the problems of thermal damage, high possibility of inverter, and high motor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, the same code|symbol in a figure shows the same or a corresponding part.

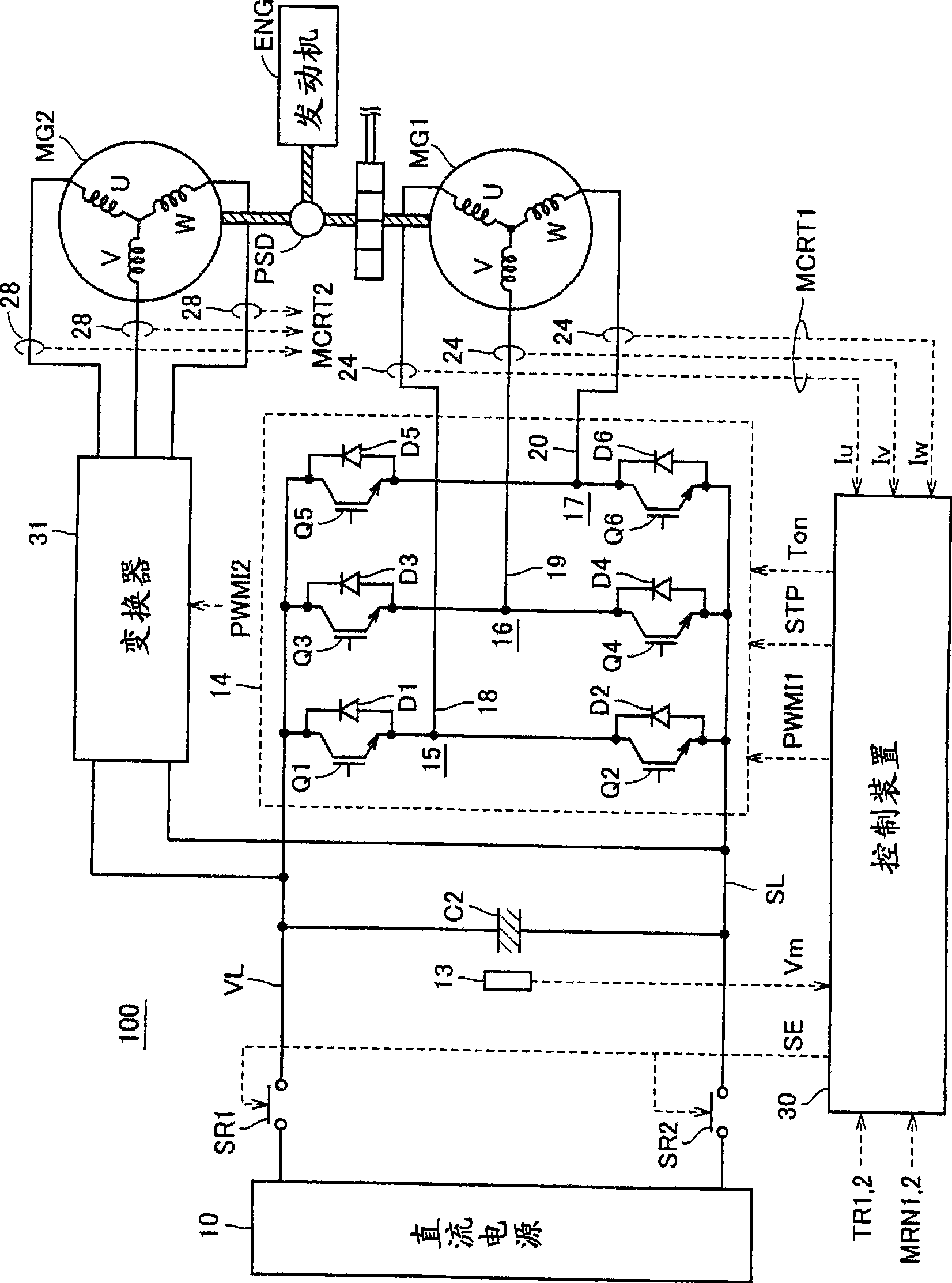

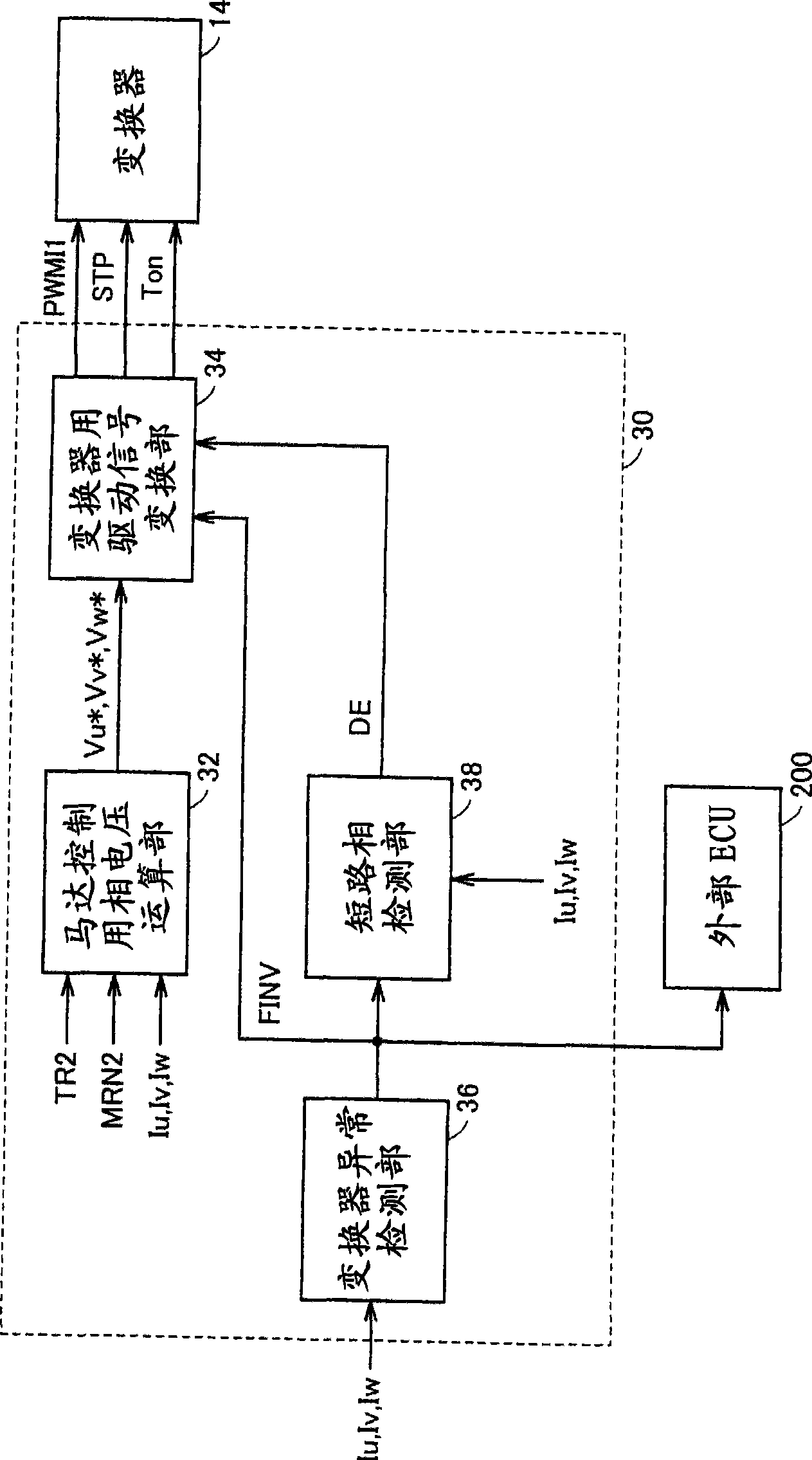

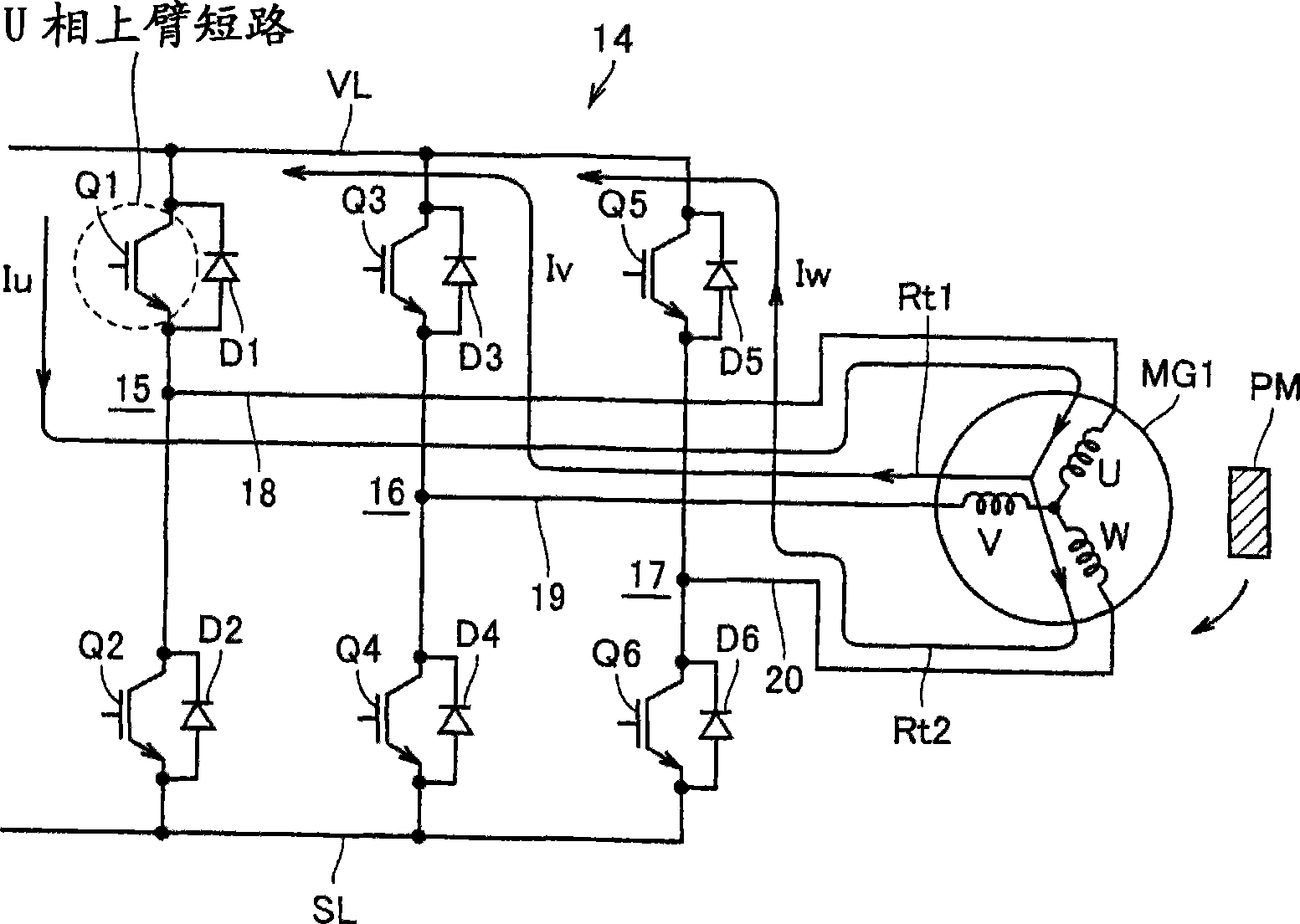

[0029] figure 1 It is a schematic block diagram of the motor drive device concerning embodiment of this invention.

[0030] refer to figure 1 , the motor drive device 100 includes a DC power supply 10 , a voltage sensor 13 , system relays SR1 , SR2 , a capacitor C2 , inverters 14 , 31 , current sensors 24 , 28 , and a control device 30 .

[0031] The engine ENG generates driving force using fuel energy of fuel such as gasoline as an energy source. The driving force generated by the engine ENG, such as figure 1 As shown by the thick oblique line in , it is divided into two paths by the power distribution mechanism PSD. One is a path that is transmitted to a drive shaft that drives the wheels via a reduction gear (not shown). The other is a route for transmission to motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com