All-negative pressure continuous-mining continuous-filling step-by-step replacement mining method for coal underneath cities and towns, industrial buildings, railways and other buildings

A full negative pressure, continuous mining technology, applied in safety devices, fillings, ground mining, etc., can solve the problems of poor safety of full negative pressure ventilation system, mutual influence between filling and production, and many filling support equipment, etc., to achieve equipment occupation. The effect of less, less personnel occupancy and high degree of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

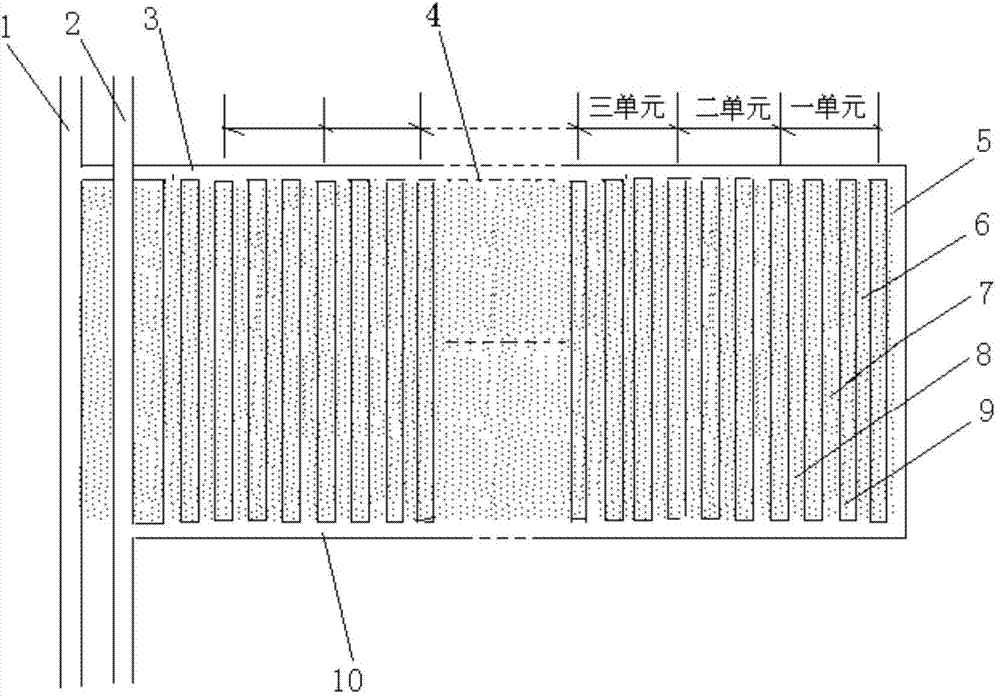

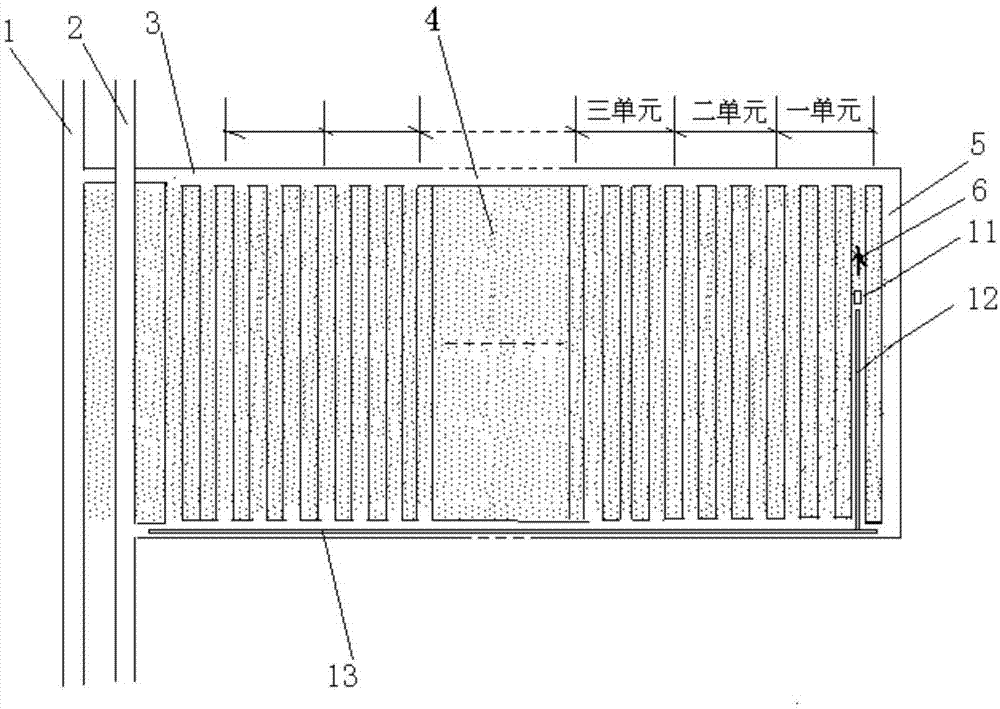

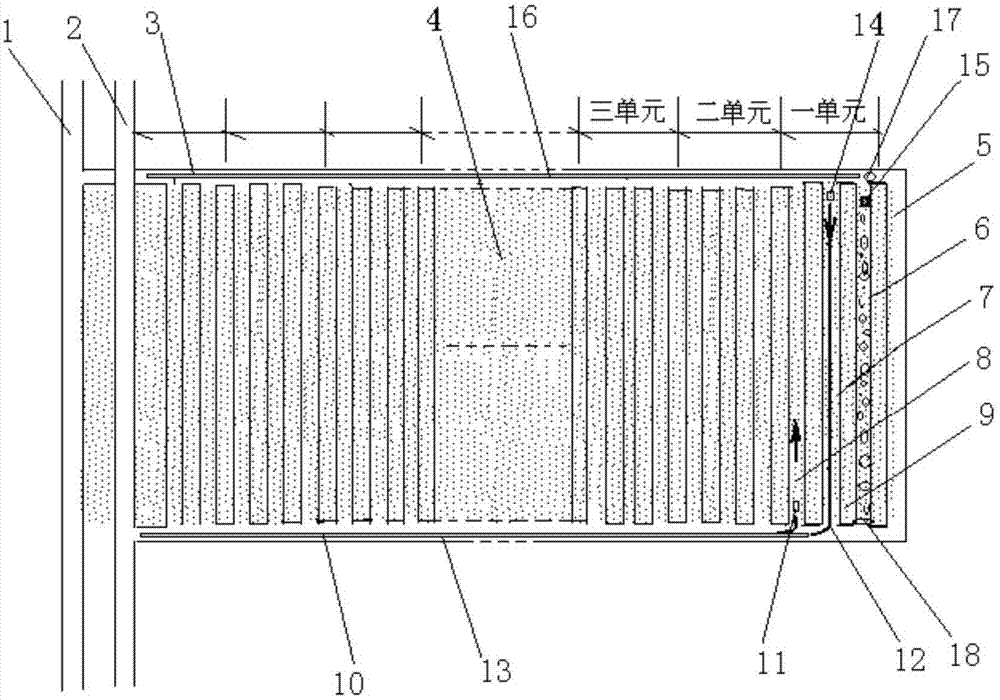

[0041] A full negative pressure continuous mining and full step replacement "three down" coal mining method, such as figure 1 The steps shown are as follows:

[0042] The first step is to arrange the work surface

[0043] like figure 1 As shown, first in the "three down" coal mining section 4, according to the conventional mining area layout method, excavate and exit the transportation uphill roadway 2 and the return air uphill roadway 1, and determine the transportation chute 10 and The position of the return air trough 3; in the transport uphill roadway 2, excavate the transport chute 10 along the working face; Excavation cutout 5 at the edge of section 4; forming an upward-type full negative pressure ventilation system for this coal mining section;

[0044] Then divide the entire "three lower" coal mining section 4 into several production units, starting from the edge of the section from the inside to the outside in order of unit 1, unit 2..., each production unit consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com