Method for preparing amide/imide type high-concentration polycarboxylic acid high-performance water reducer

An imide-type, polycarboxylic acid-based technology, applied in the field of chemical building materials and construction, can solve problems such as difficult actual production, high cost, and complex synthesis process, and achieve reduced synthesis and transportation costs, stable product performance, and acylation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

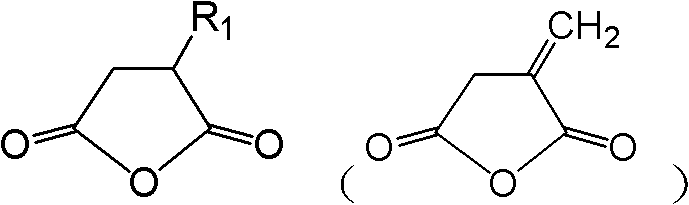

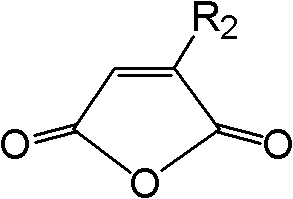

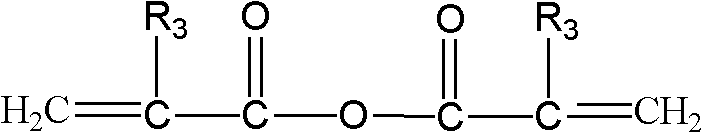

Method used

Image

Examples

Embodiment 1

[0056] (1) Acylation reaction: Neutralize 60.00 g of monoethanolamine with equimolar acetic acid and add 140.00 g of maleic anhydride into the reactor. Under the protection of nitrogen, heat up to 60 ° C, add 0.32 g of concentrated sulfuric acid, and continue Raise the temperature to 85°C, keep the temperature constant for 3 hours, and then lower the temperature to obtain the acylated product A.

[0057] (2) Esterification reaction: Add 240.00 g of polyethylene glycol monomethyl ether with a molecular weight of 600, 100.00 g of acrylic acid, and 0.70 g of p-phenylenediamine into the reactor, stir and heat, and when the temperature rises to 60°C, add 7.20 g of sulfuric acid g. Continue to raise the temperature to 130°C, and react at this temperature for 1.5h to obtain the esterification product B.

[0058] (3) Copolymerization: To the reactor containing 17.50 g of sodium methacrylate, 56.95 g of acylated product A, and 30.00 g of water, 157.84 g of esterified product B and 24....

Embodiment 2

[0061] (1) Acylation reaction: neutralize 70.00g of monopropanolamine with equimolar acetic acid and add 124.00g of itaconic anhydride into the reactor. Under the protection of nitrogen, heat up to 60°C and add 0.41g of concentrated sulfuric acid , continue to raise the temperature to 90° C., keep the temperature constant for 3 hours, and cool down to obtain the acylated product A.

[0062] (2) Esterification reaction: Add 240.00 g of polyethylene glycol monomethyl ether with a molecular weight of 1200, 130.00 g of maleic acid, and 0.51 g of p-phenylenediamine into the reactor, stir and heat, and when the temperature rises to 60°C, add 11.00 g of p-toluenesulfonic acid. Continue to raise the temperature to 110°C, and react at this temperature for 2.5 hours to obtain the esterified product B.

[0063] (3) Copolymerization reaction: In the reactor containing 20.00 g of sodium allyl sulfonate, 70.00 g of acylated product A, and 30.00 g of water, 150.00 g of esterified product B ...

Embodiment 3

[0066] (1) Acylation reaction: neutralize 60.00g of monoisopropanolamine with equimolar propionic acid and add 120.00g of 2-methylmaleic anhydride into the reactor, and raise the temperature to 60°C under the protection of nitrogen , add 0.31g of benzenesulfonic acid, continue to heat up to 95°C, keep the temperature constant for 1.5h, and cool down to obtain the acylated product A.

[0067] (2) Esterification reaction: Add 200.00 g of polyethylene glycol propylene glycol block monomethyl ether with a molecular weight of 1000, 90.00 g of methacrylic acid, and 0.70 g of benzoquinone into the reactor, stir and heat, and when the temperature rises to 60 ° C, 11.00 g of benzenesulfonic acid was added. Continue to raise the temperature to 120°C, and react at this temperature for 2 hours to obtain the esterification product B.

[0068] (3) Copolymerization reaction: Into the reactor containing 30.00 g of sodium styrene sulfonate, 100.00 g of acylate product A, and 35.00 g of water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com