Heteroatom doped leaf-shaped carbon nanometer aerogel material and preparation method and application thereof

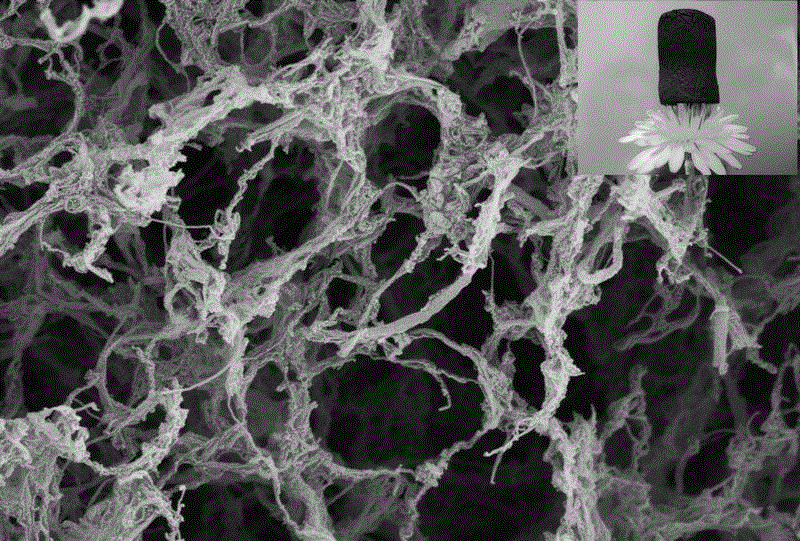

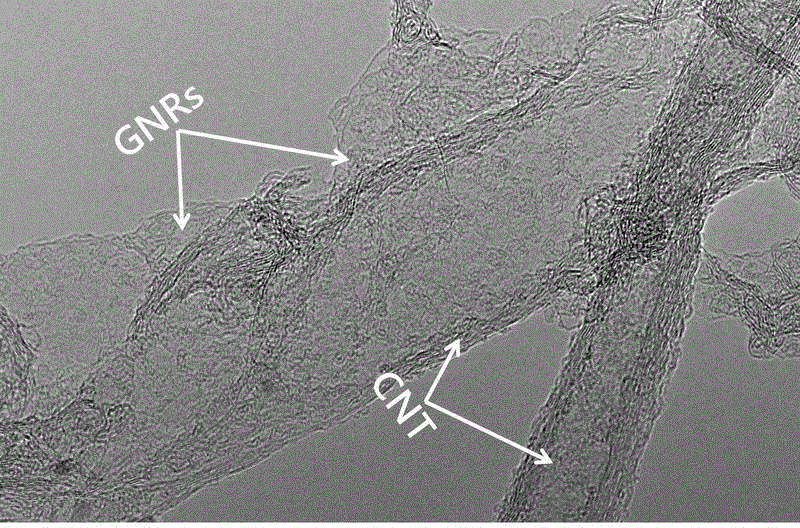

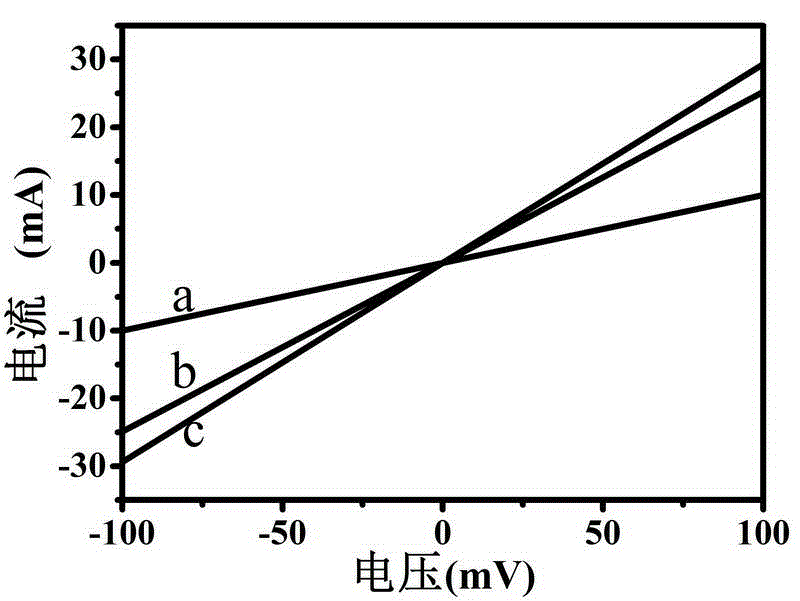

A carbon nanomaterial and leaf-shaped technology, which is applied in the field of carbon nanoairgel materials and its preparation, can solve problems such as hindering electron transport and mass transport, catalytic performance discount, low specific surface area, etc., and achieve rapid electron transport and mass transport And fully, the effect of inhibiting aggregation problems, large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Take 10 mL of a 0.1 mg / mL leaf-shaped carbon nanomaterial solution, add 100 mg of pyrrole as a N source, and disperse ultrasonically until a uniform suspension is formed1.

[0052] (2) Seal the suspension 1 in a 20 mL hydrothermal reaction kettle and place it at 180 o React in an oven at C for 6 h to obtain blocky hydrogel.

[0053] (3) Add ethanol to the hydrogel, pour out the ethanol after soaking for 10 h, repeat 4 times, add water to the hydrogel, pour out the water after soaking for 10 h, repeat 2 times, pour out Glue at -25 oC Freeze for ≥30 min, then at 70 o C drying for 30 min to obtain leaf-shaped carbon nanomaterial aerogels; both freezing and drying processes were carried out under a vacuum of 10 Pa.

[0054] (4) Carbonize the obtained leaf-shaped carbon nanomaterial aerogel in an argon-protected high-temperature carbonization furnace (produced by Tianjin Zhonghuan Company) for 1 hour, and the carbonization temperature is 1000 o C, the heating rate i...

Embodiment 2

[0056] (1) Take 15 mL of 20 mg / mL leaf-shaped carbon nanomaterial solution, add 1 mL of ammonia water as a N source, and disperse ultrasonically until a uniform suspension is formed.

[0057] (2) Seal the suspension 2 in a 20 mL hydrothermal reaction kettle and place it at 120 o C in an oven for 12 h to obtain block hydrogel.

[0058] (3) Add ethanol to the hydrogel, pour out the ethanol after soaking for 10 h, and repeat 5 times to obtain an alcohol gel. 2 Desiccator drying for 24 h, supercritical CO 2 The critical temperature for drying is 40 o C, the critical pressure is 7.5 Pa, and the leaf-like carbon nanomaterial airgel is obtained.

[0059] (4) The obtained leaf-shaped carbon nanomaterial airgel was carbonized in a nitrogen-protected high-temperature carbonization furnace (produced by Tianjin Zhonghuan Company) for 6 h, and the carbonization temperature was 800 o C, the heating rate is 20 o C / min, the cooling rate is 10 o C / min. A nitrogen-doped leaf-shaped carbo...

Embodiment 3

[0061] (1) Take 30 mL of a 1 mg / mL leaf-shaped carbon nanomaterial solution, add 100 mg of triphenylphosphine as a P source, and disperse ultrasonically until a uniform suspension is formed3.

[0062] (2) Seal the suspension 3 in a 50 mL hydrothermal reactor and place it at 200 o C in an oven for 20 h to obtain block hydrogel.

[0063] (3) Add ethanol to the hydrogel, pour out the ethanol after soaking for 5 h, repeat 4 times, add water to the hydrogel, pour out the water after soaking for 5 h, repeat 6 times, pour the water Glue at -70 oC Freeze for ≥30 min, then at 40 o C dried for 24 h to obtain leaf-like carbon nanomaterial aerogels; both freezing and drying processes were carried out under a vacuum of 10 Pa.

[0064] (4) The obtained leaf-shaped carbon nanomaterial airgel was carbonized in an argon-protected high-temperature carbonization furnace (produced by Tianjin Zhonghuan Company) for 3 h, and the carbonization temperature was 900 o C, the heating rate is 10 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com