Camellia nitidissima tea and processing technology thereof

A processing technology, golden camellia technology, which is applied in the field of golden camellia and its processing technology, can solve the problems of flower vitamin C and vitamin E component loss, long drying time, and reduced commerciality, so as to avoid easy discoloration, facilitate storage, High practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The processing technology of Camellia japonica provided by the present embodiment comprises the following steps:

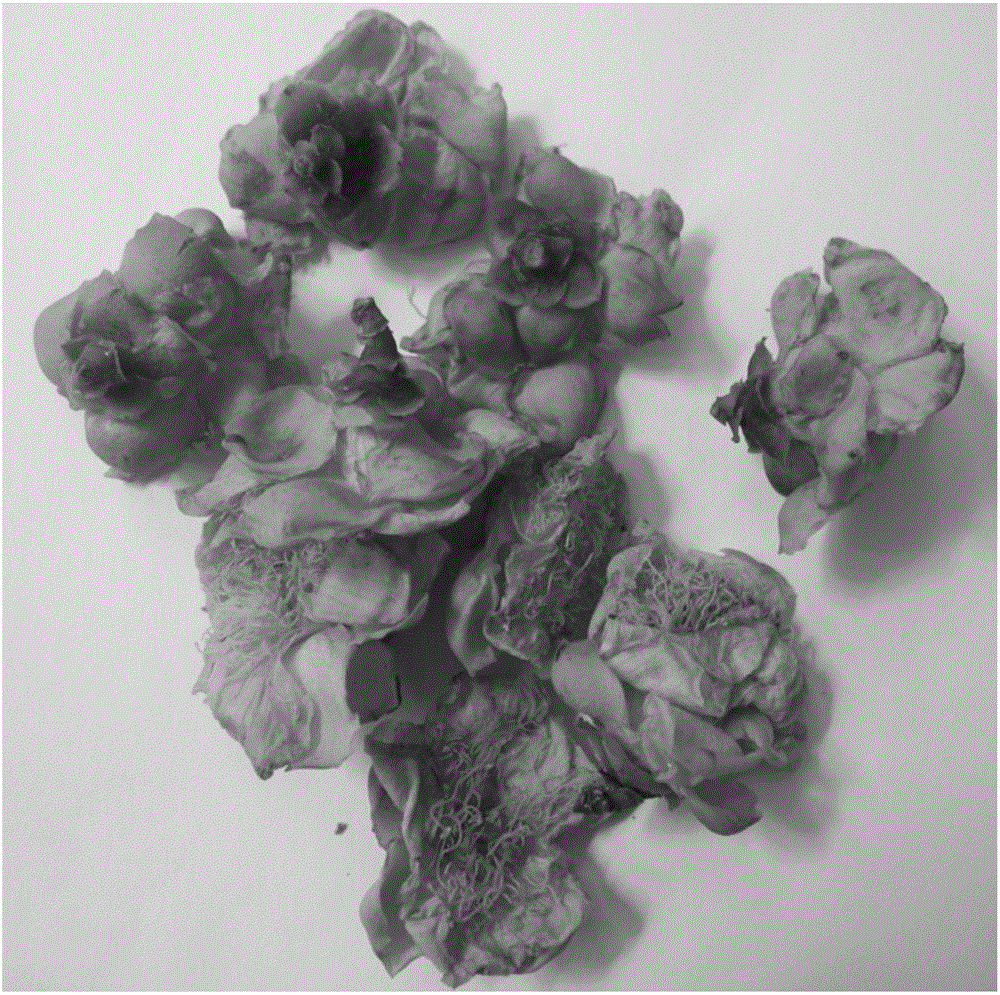

[0054] a. Pick the flowers of Camellia japonica in the fresh flower bud stage, wither the flowers for 3 hours at 23°C, and the thickness of the flowers is 3cm;

[0055] b. Lay the withered flowers in a single layer on the conveyor belt of the microwave killing machine, adjust the frequency of the microwave killing machine to 2400MHz, the power to 13.5kW, and the speed to 300rpm, and set the transmission speed of the conveyor belt to 1.6m / min. The flowers are cleaned by microwave until the water content of the flowers is 70wt%;

[0056] c. Lay the flowers in a single layer on a sieve, and pre-freeze at -20°C for 3 hours;

[0057] d. Put the pre-frozen flowers into a vacuum dryer to dry. When the temperature of the refrigeration tube of the vacuum dryer reaches -20°C, turn on the vacuum system. When the vacuum pressure is -0.12MPa, turn on the vacuum dryer. ...

Embodiment 2

[0061] The processing technology of Camellia japonica provided by the present embodiment comprises the following steps:

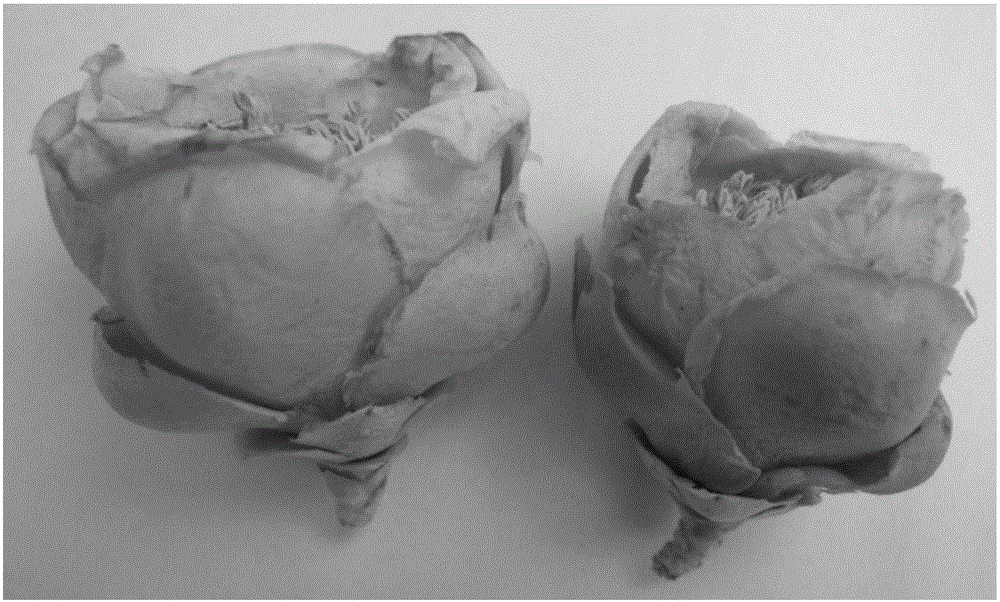

[0062] a. Pick fresh flowers of Camellia japonica in the flowering stage, wither the flowers for 4 hours at 28° C., and spread the flowers to a thickness of 4 cm;

[0063] b. Lay the withered flowers in a single layer on the conveyor belt of the microwave killing machine, adjust the frequency of the microwave killing machine to 2500MHz, the power to 13.5kW, and the speed to 350rpm, and set the transmission speed of the conveyor belt to 2.66m / min. The flowers are microwaved until the water content of the flowers is 75wt%;

[0064] c. Cool the flowers to 25°C, and then spray the auxiliary liquid on the flowers. The spraying amount of the auxiliary liquid is 30mL / m 2 , the auxiliary liquid is a mixture of honey and the extraction liquid of camellia camellia flowers, the volume ratio of honey and extraction liquid is 1:6, and the flowers need to be turned twic...

Embodiment 3

[0070] The processing technology of Camellia japonica provided by the present embodiment comprises the following steps:

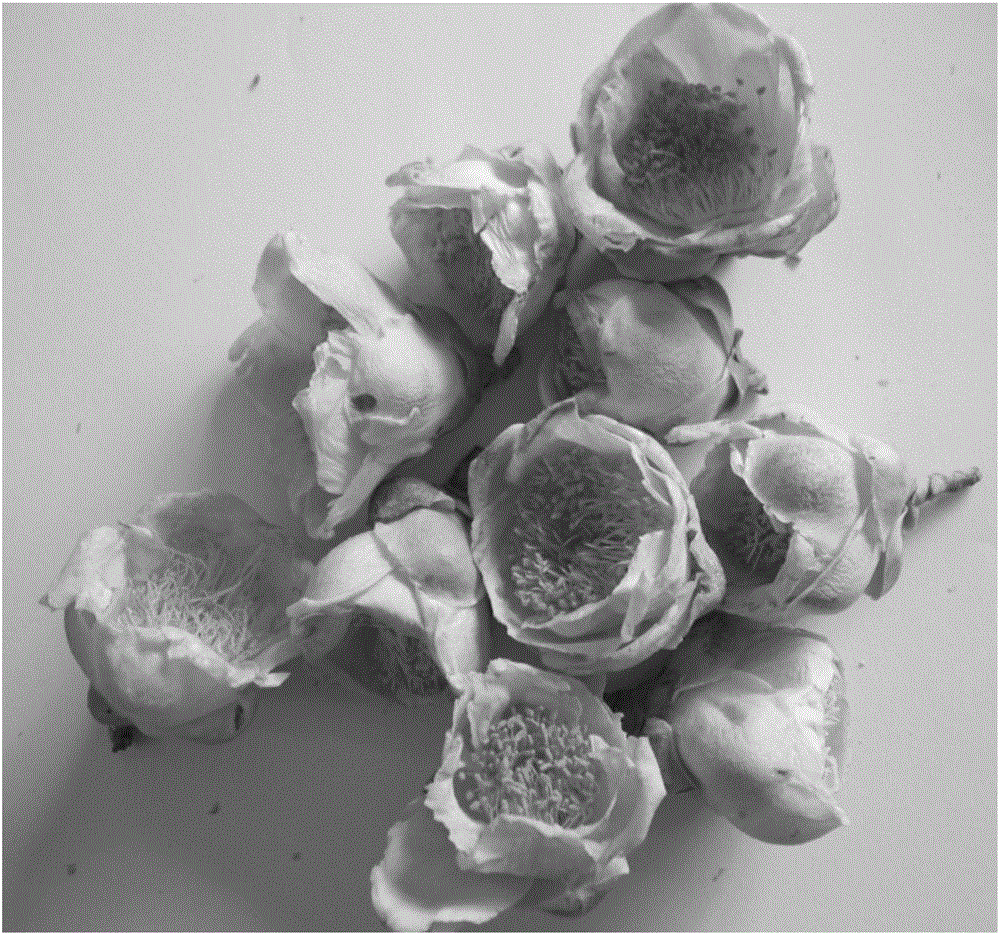

[0071] a. Picking fresh flowers of Camellia japonica at the flowering stage, withering the flowers for 3.5 hours at 25° C., and spreading the flowers to a thickness of 3 cm.

[0072] b. Lay the withered flowers in a single layer evenly on the conveyor belt of the microwave cleaning machine, adjust the frequency of the microwave cleaning machine to 2450MHz, the power to 13.5kW, and the speed to 300rpm, and set the transmission speed of the conveyor belt to 1.6m / min , microwave the flowers until the water content of the flowers is 70wt%;

[0073] c. Cool the flowers to 18°C, then lay the flowers in a single layer, and pre-freeze them at -15°C for 3 hours;

[0074] d. Put the pre-frozen flowers into the vacuum dryer to dry. When the temperature of the refrigeration tube of the vacuum dryer reaches -20°C, turn on the vacuum system. When the vacuum pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com