Stable and lasting dental implant structure

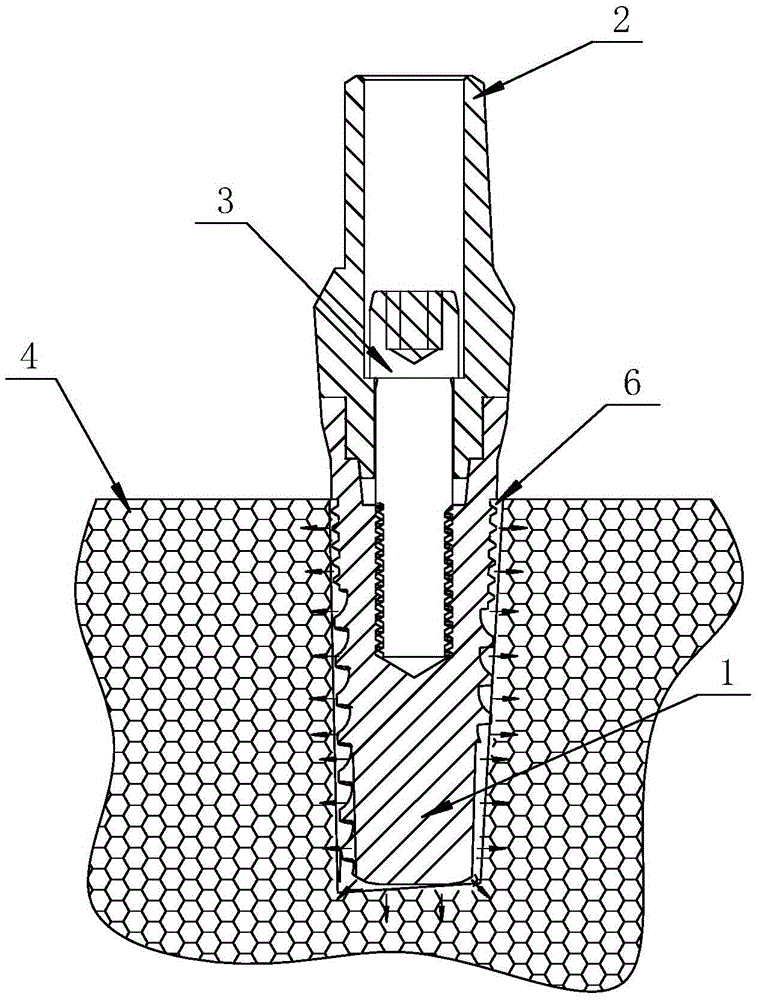

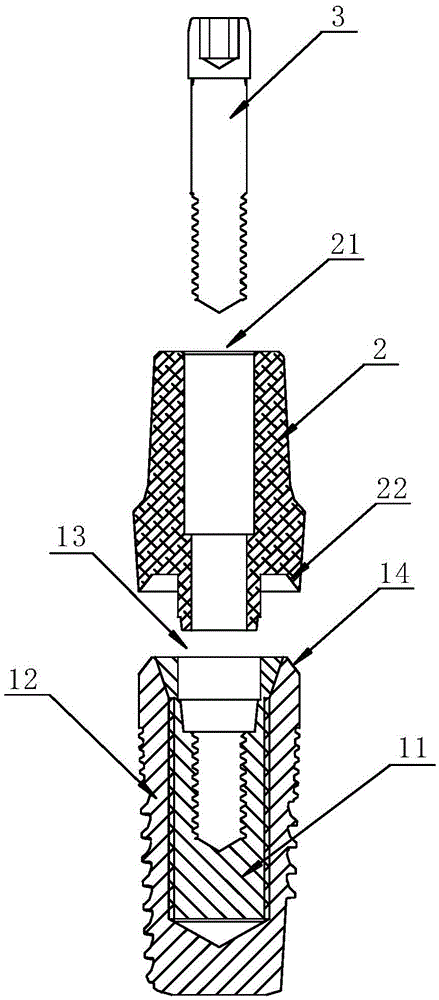

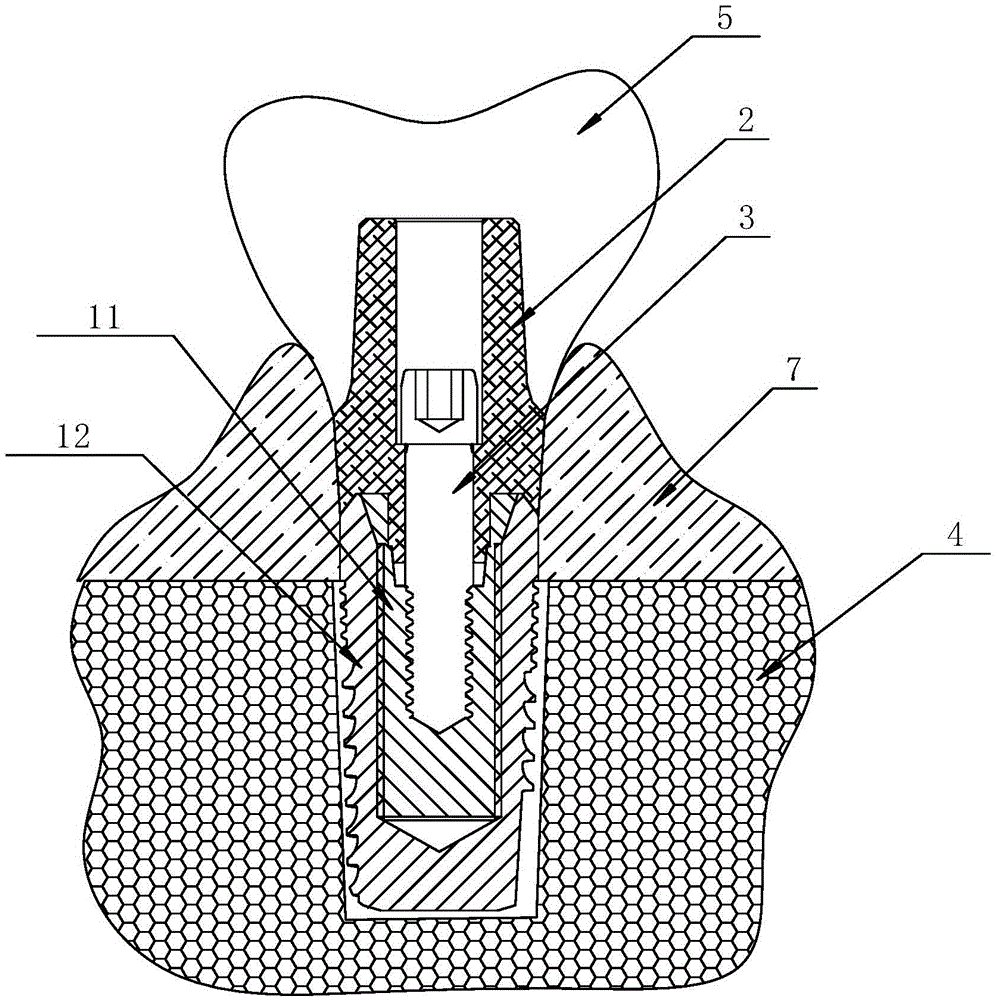

A technology for dental implants and implants, which is applied in the field of oral medicine, can solve the problems of loosening of implants and alveolar bone 4, loosening of central bolts 3, affecting the function of implants, etc., and achieves the effect of good biocompatibility and prevention of falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a. Use sandblasting medium at a pressure of 0.5Mpa to spray the part of the surface of the implant (that is, the jacket 12, the same below) that needs to be implanted into the alveolar bone. The spraying distance is 40mm, and the angle between the spraying direction and the axial direction of the implant is 30° and 150° alternately, but the last sandblasting is sprayed from the crown towards the root; until the surface of the implant loses its metallic luster and turns gray; in this way, uniform micropores or small concave holes with a certain size are formed on the pure titanium surface. Pit, micropore diameter 50 ~ 150μm.

[0037] In sandblasting, the particle size of the sandblasting medium is 0.1-0.3mm, and the weight composition is 80% of white corundum, 6% of titanium phosphate, and 14% of corundum.

[0038] b. Rinse the surface of the implant with anhydrous purified water 4 times, each time for 2 minutes, to remove the sandblasting medium remaining on the surface...

Embodiment 2

[0042] a. Use sandblasting medium at a pressure of 0.6Mpa to spray the part of the implant surface that needs to be implanted into the alveolar bone. The spraying distance is 80mm, and the angle between the spraying direction and the axial direction of the implant is 45° and 135° alternately, but the last pass Sandblasting is sprayed from the crown towards the root until the surface of the implant loses its metallic luster and turns gray; in this way, uniform micropores or small pits with a certain size are formed on the pure titanium surface, with a micropore diameter of 50-150 μm.

[0043] In sandblasting, the particle size of the sandblasting medium is 0.1-0.3mm, and the weight composition is 90% of white corundum, 2% of titanium phosphate, and 8% of corundum.

[0044] b. Rinse the surface of the implant with absolute ethanol for 5 times, each time for 2 minutes, to remove the sandblasting medium remaining on the surface;

[0045] c. Put it into the mixed acid solution, and...

Embodiment 3

[0048] a. Use sandblasting medium at a pressure of 0.55Mpa to spray the part of the implant surface that needs to be implanted into the alveolar bone. The spraying distance is 60mm. The angle between the spraying direction and the axial direction of the implant is 60° and 120° alternately, but the last pass Sandblasting is sprayed from the crown towards the root until the surface of the implant loses its metallic luster and turns gray; in this way, uniform micropores or small pits with a certain size are formed on the pure titanium surface, with a micropore diameter of 50-150 μm.

[0049] In sandblasting, the particle size of the sandblasting medium is 0.1-0.3mm, and the weight composition is 85% of white corundum, 3% of titanium phosphate, and 12% of corundum.

[0050] b. Rinse the surface of the implant with purified water for 5 times, 2 minutes each time, to remove the sandblasting medium remaining on the surface;

[0051] c. Put it into the mixed acid solution, and carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com