Treatment method suitable for carrying and storing plastic-lined steel pipes

A processing method and technology of steel pipes, applied in transportation, packaging, closing, packaging, etc., can solve problems affecting work efficiency, easy to drop hands, work-related accidents, etc., and achieve the effects of improving quality, facilitating operation and installation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

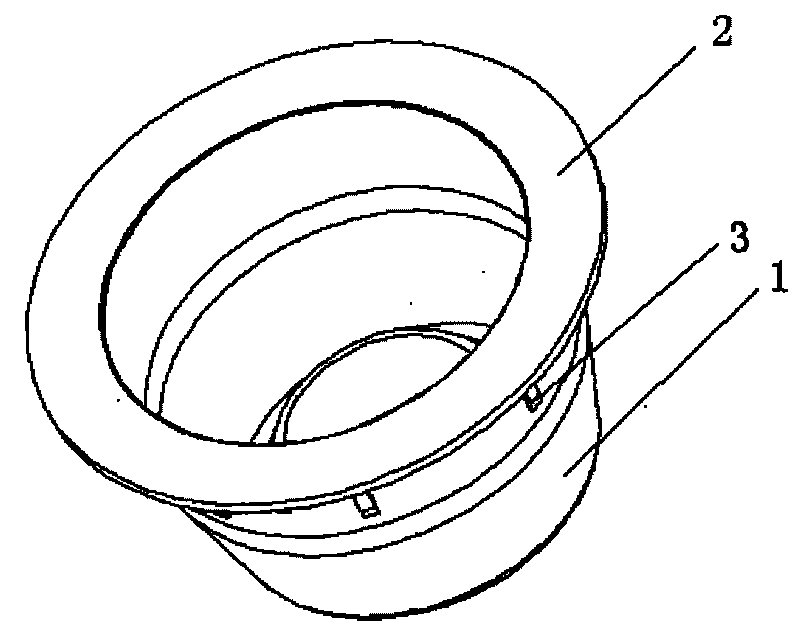

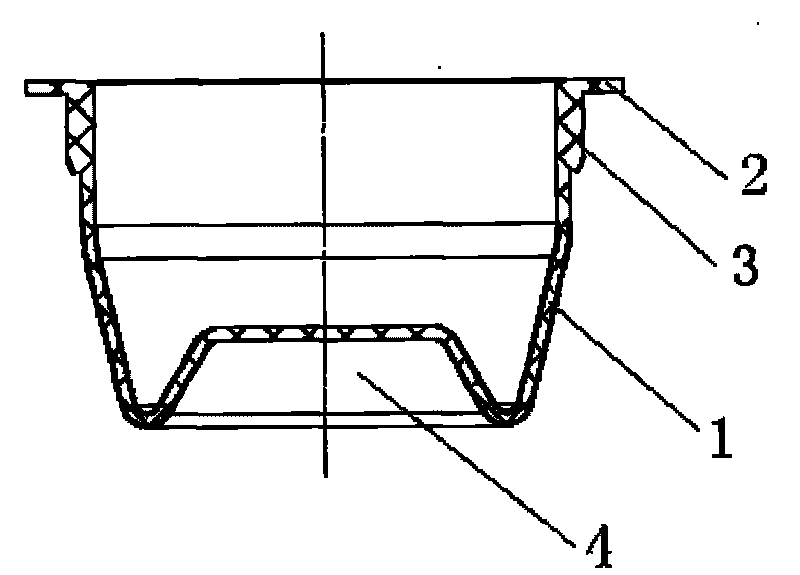

[0021] The pipe cap structure that the present invention adopts is as attached figure 2 , 3 As shown, including the bowl 1 and the outer edge 2, the outer surface of the bowl 1 is uniformly provided with reinforcing ribs 3, and the bottom of the outer surface of the bowl 1 is arched to form a concave part 4.

[0022] The operation of the present invention is as attached Figure 4 As shown, the bowl 1 is inserted into the port of the plastic-lined steel pipe 5, and the outer edge 2 covers the end face of the plastic-lined steel pipe 5, which supports the plastic-lined steel pipe through the evenly distributed reinforcing ribs 3 provided on the outer surface of the bowl 1. The adhesive layer of the tube 5, no matter how long the product is placed, the port will not be delaminated due to shrinkage, which improves the quality of the product. The design depth of the bow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com