Cementing material and preparation method thereof

A technology for cementitious materials and fly ash, which is applied in the field of building materials and can solve the problems of slow solidification, low early strength, and large differences in early strength effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

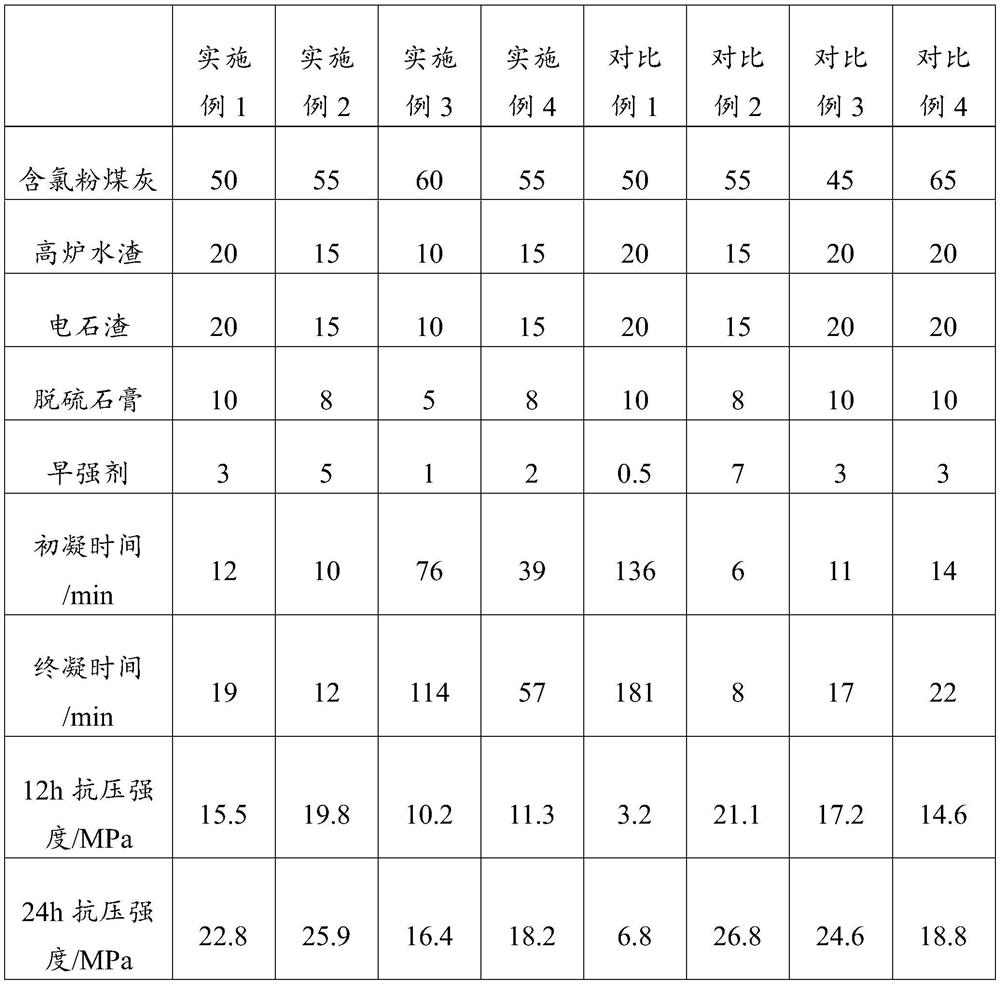

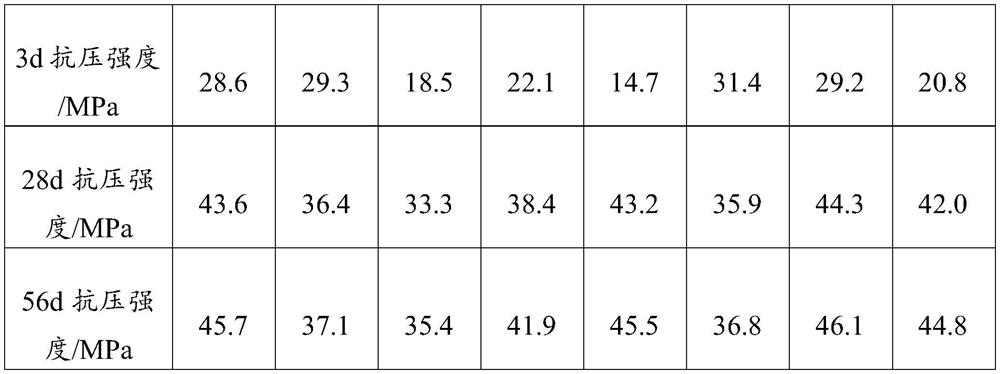

[0034] The components of the cementitious materials of Examples 1-4 and Comparative Examples 1-4 are shown in Table 1, wherein the early strength agent is 40-50 parts of aluminum iron sulfate, 30-40 parts of sodium sulfate, and 10-20 parts of potassium aluminate and 5-10 parts of sodium metaphosphate.

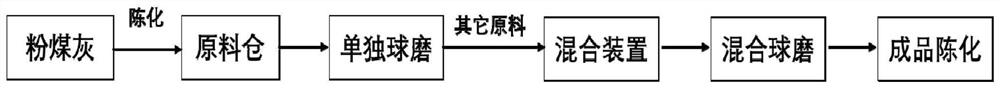

[0035] The preparation method of embodiment 1~4 and comparative example 1~4 cementitious material comprises the following steps:

[0036] (1) Stand and age chlorine-containing fly ash for 7 days, then place ball milling in a ball mill, test the specific surface area of chlorine-containing fly ash after ball milling, wherein the ball milling speed is 60-100r / min, and the ball milling time is 12- 18h, the specific surface area of chlorine-containing fly ash is 400-500m 2 / kg;

[0037] (2) Stir the chlorine-containing fly ash and other components after ball milling in step (1), then place ball milling in a ball mill, test the specific surface area of the mixed material aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com