Fretting fatigue surface crack detection method and system

A technology for fretting fatigue and surface cracks, which is applied in the direction of applying repetitive force/pulsation force to test material strength, measuring devices, and testing of mechanical components. It can solve the impact of sample fatigue life, cannot effectively measure cracks, and has low monitoring accuracy. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

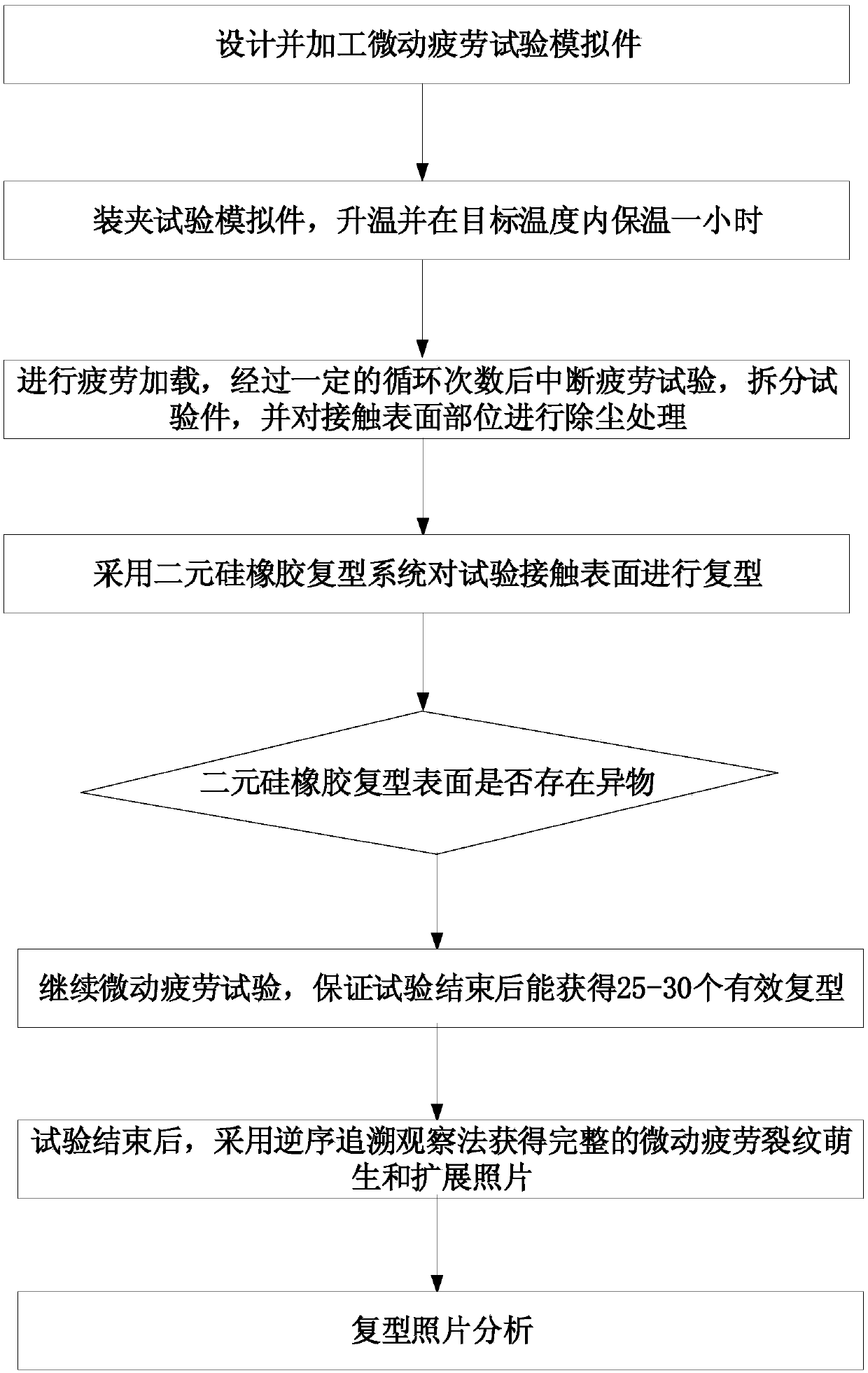

[0053] Combine below Figure 1 to Figure 6 The technical solution provided by the present invention is described in more detail.

[0054] First introduce the nouns or terms involved in this article.

[0055] Fretting fatigue: refers to the fact that a component or material is subject to fretting damage on a certain part of the surface on the one hand, and on the other hand, it also bears a large external fatigue load. Break failure.

[0056] Surface crack (stress concentration): refers to the formation or propagation of cracks on the surface of components or materials.

[0057] see image 3 , an embodiment of the present invention provides a method for detecting fretting fatigue surface cracks, comprising the following steps:

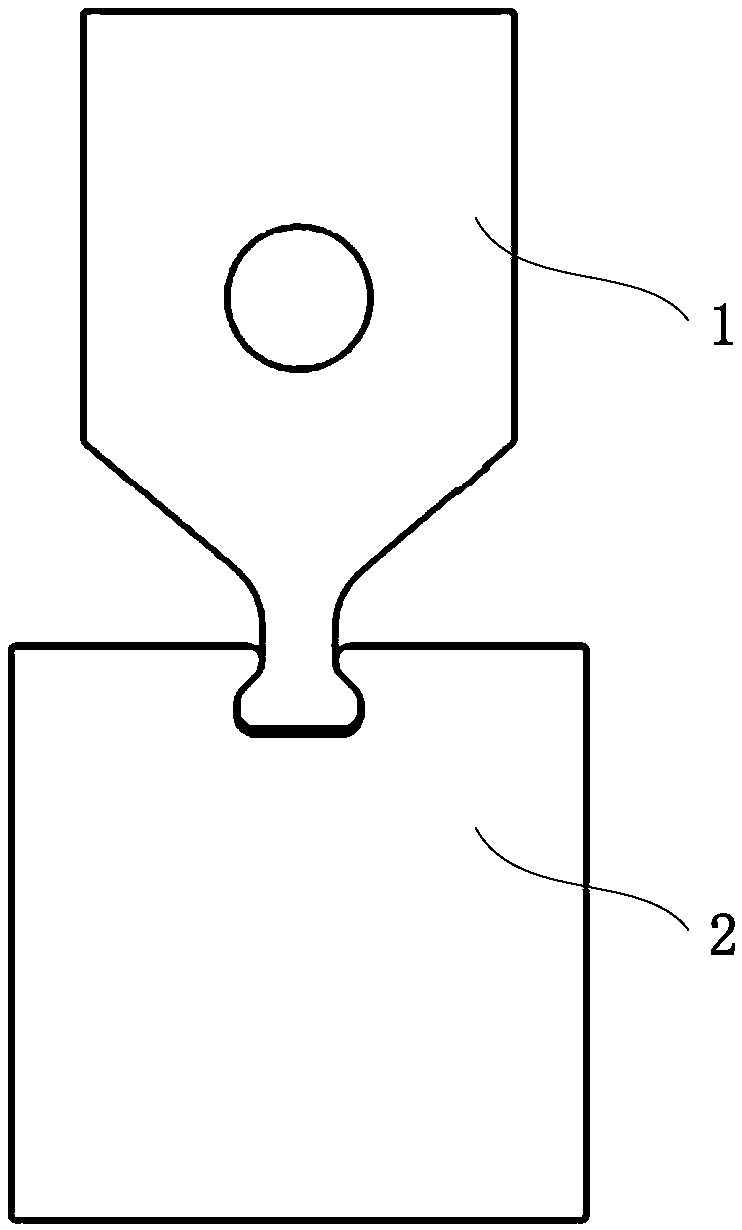

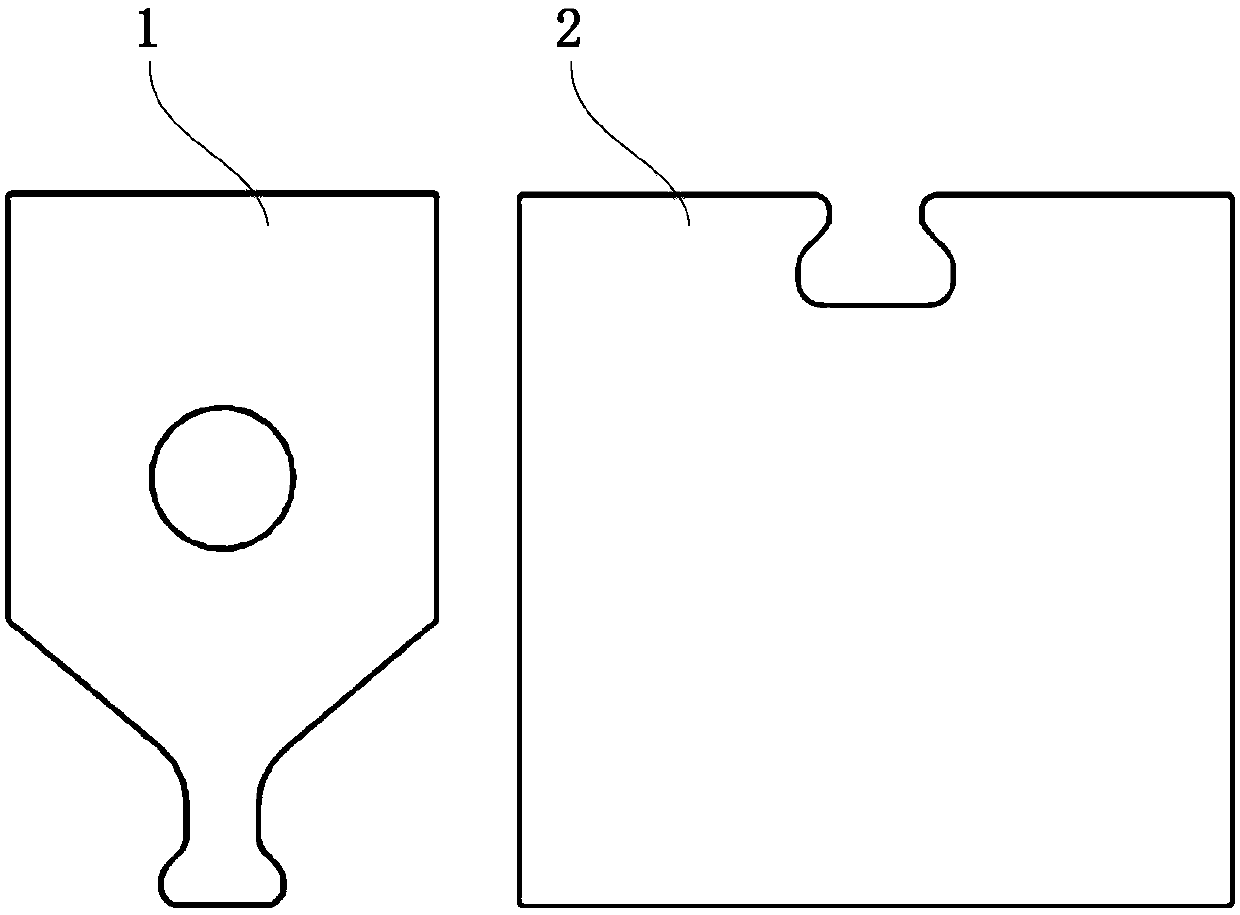

[0058] Step S10 , performing fatigue loading for a set number of times on the two cooperating first component 1 and second component 2 .

[0059] In some embodiments, the first part 1 comprises a tenon and the second part 2 comprises a tongue and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com