Pile-up noise reduction own coding network bearing fault diagnosis method based on particle swarm optimization

A self-encoding network and particle swarm optimization technology, applied in the field of bearing fault diagnosis of stacked noise reduction self-encoding network based on particle swarm optimization, can solve problems such as weak generalization performance, achieve robustness, good feature learning ability, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

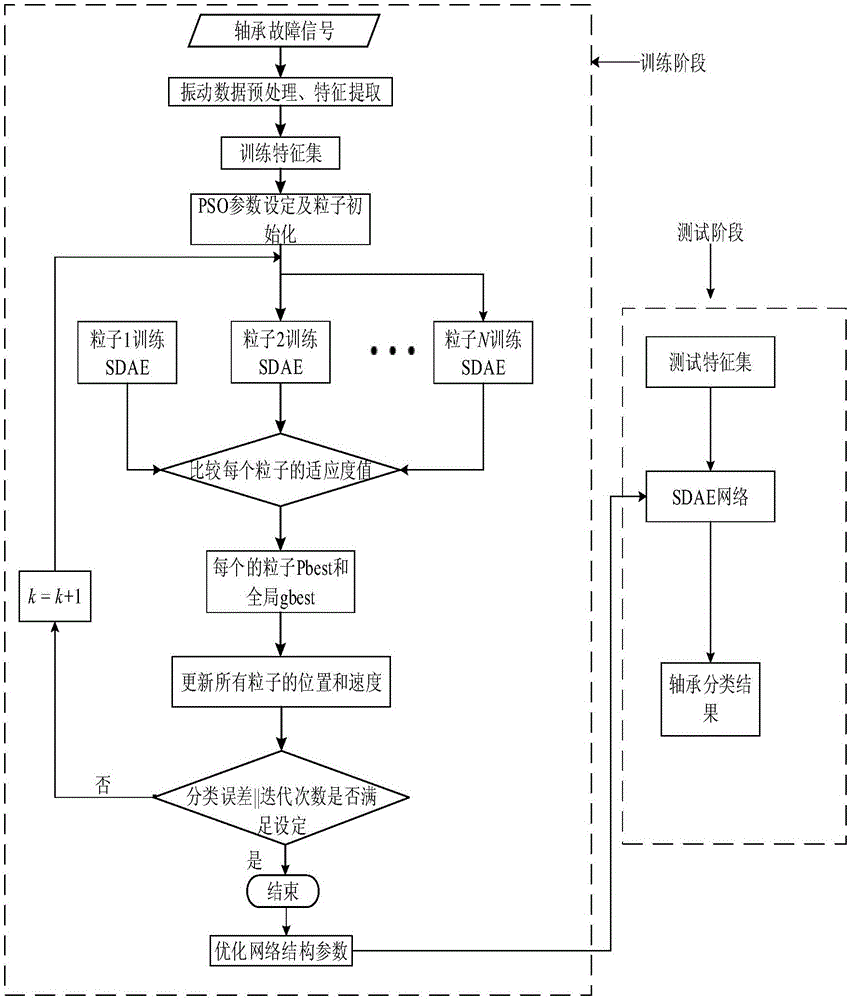

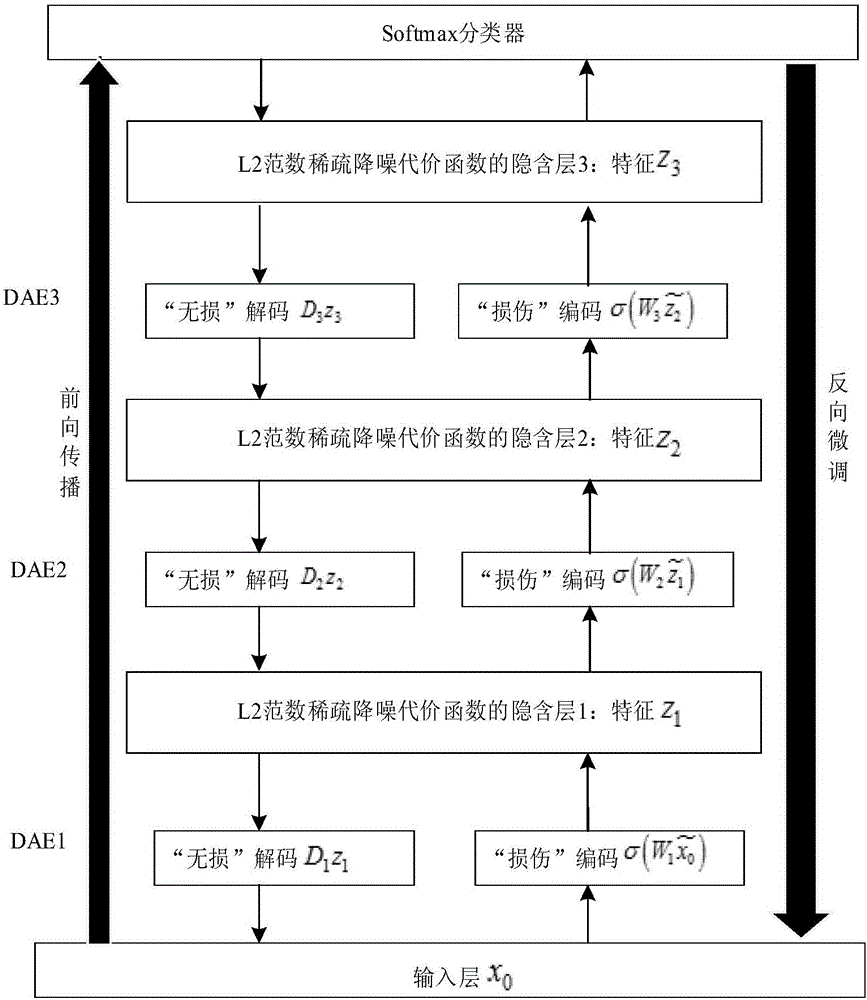

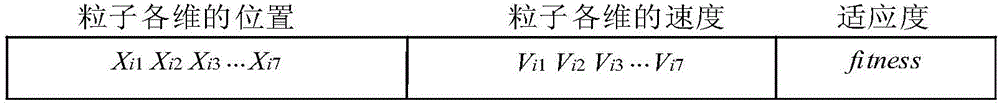

Method used

Image

Examples

Embodiment example

[0079] (1) Test data

[0080] The bearing fault test is carried out on the rotating machinery test bench. The structure of the experimental platform is as follows: Figure 4 shown. It is composed of frequency conversion speed regulating motor 1, transmission belt 2, bearing seat 3, bearing 4, acceleration sensor 5 and rotating shaft 6. The faulty bearing 4 is installed in the bearing seat 3 where the rotating shaft 6 is fixed at the 2nd position, and the bearing seat at the 2nd position 3 is equipped with an acceleration sensor 5; the vibration signal of the bearing 4 is collected with the acceleration sensor 5 installed on the bearing seat 3. The outer ring and the inner ring of the bearing 4 are processed by wire cutting with a depth of 0.5mm and three different grooves with a width of 0.5mm, 1mm and 2mm, respectively, to simulate mild, moderate and severe faults of different parts of the bearing respectively. Bearing vibration signals with rotating speeds of 800, 1100, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com