Tool damage online and in-situ detection system in clean cutting environment and method

A detection system and cleaning system technology, applied in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve the problem of unfavorable flexible manufacturing system production and economic benefits improvement, unable to detect tool grinding/broken state changes process, the lack of visual system protection devices and tool cleaning devices, etc., to improve production efficiency and economic benefits, improve tool damage detection efficiency and reliability, and improve detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

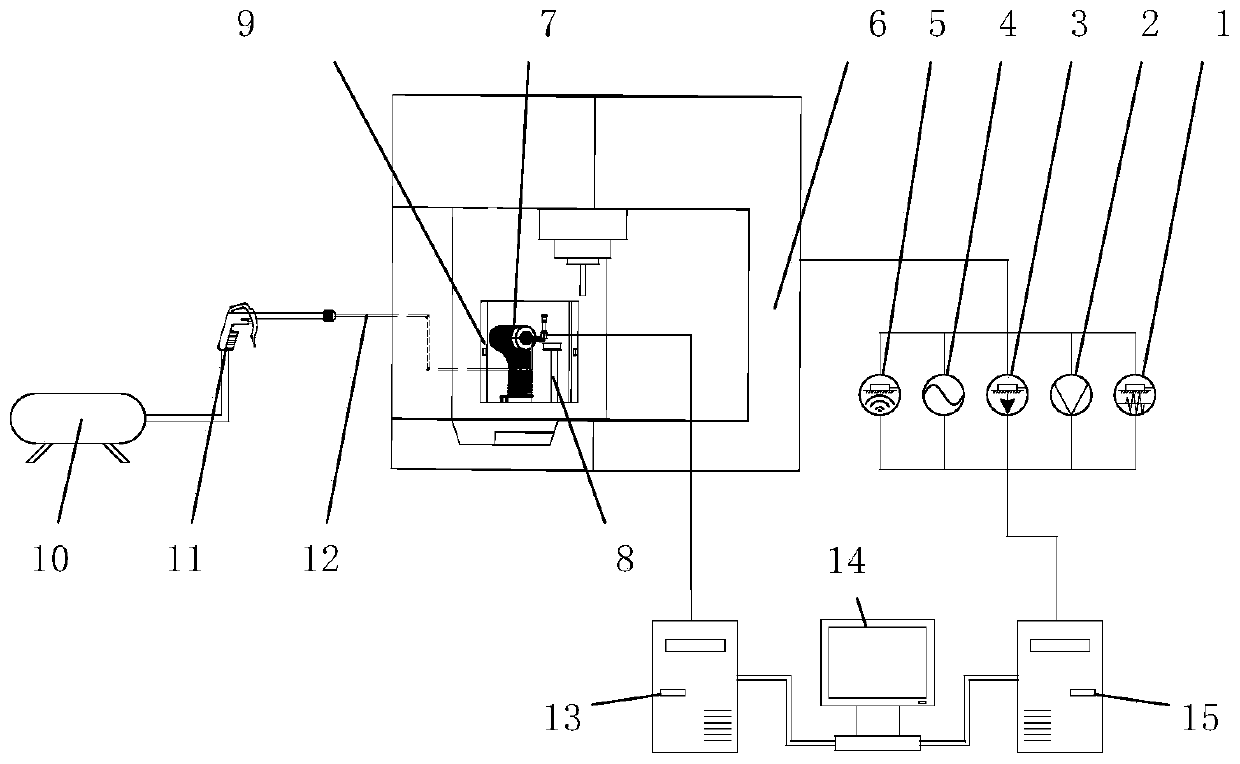

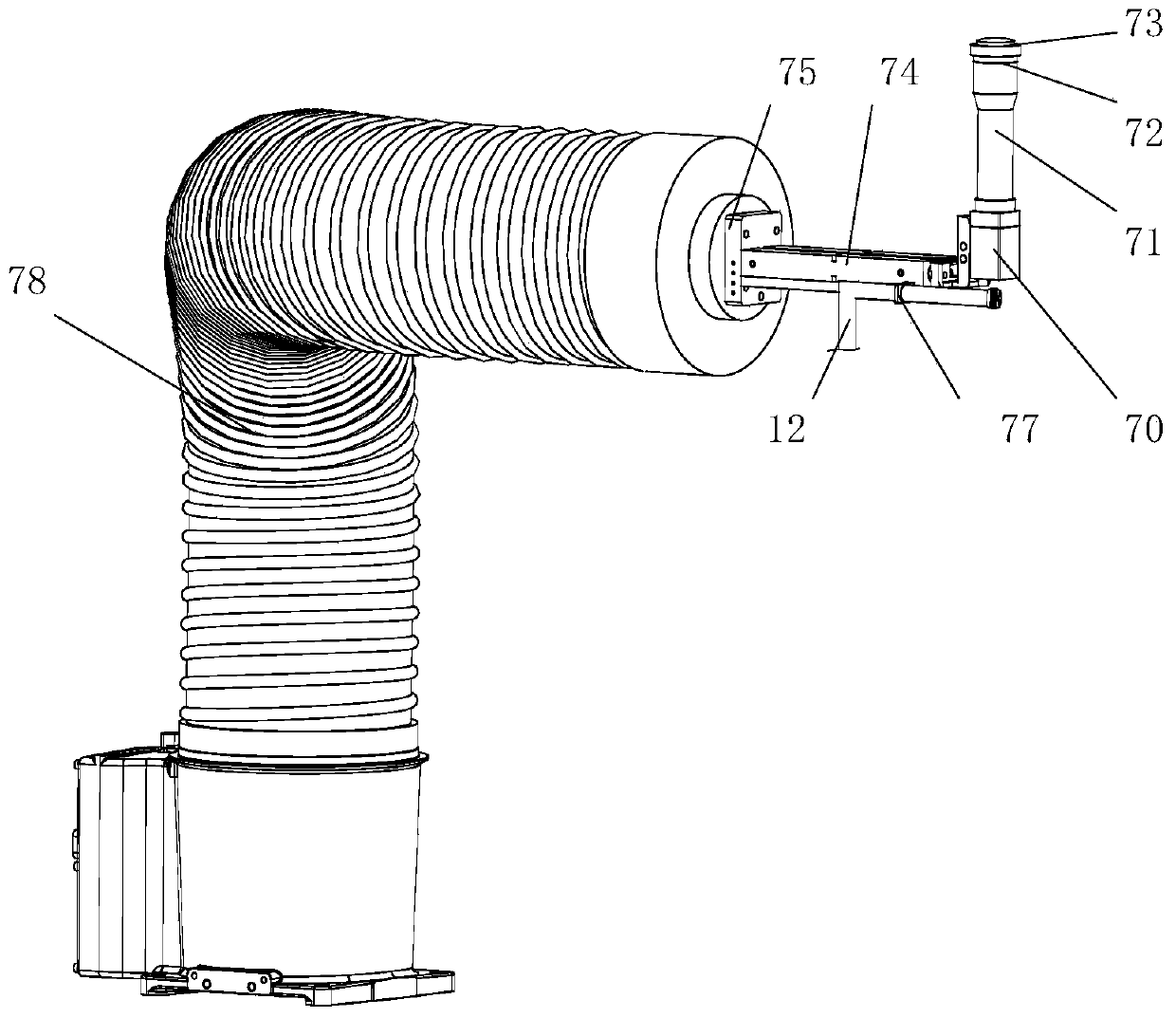

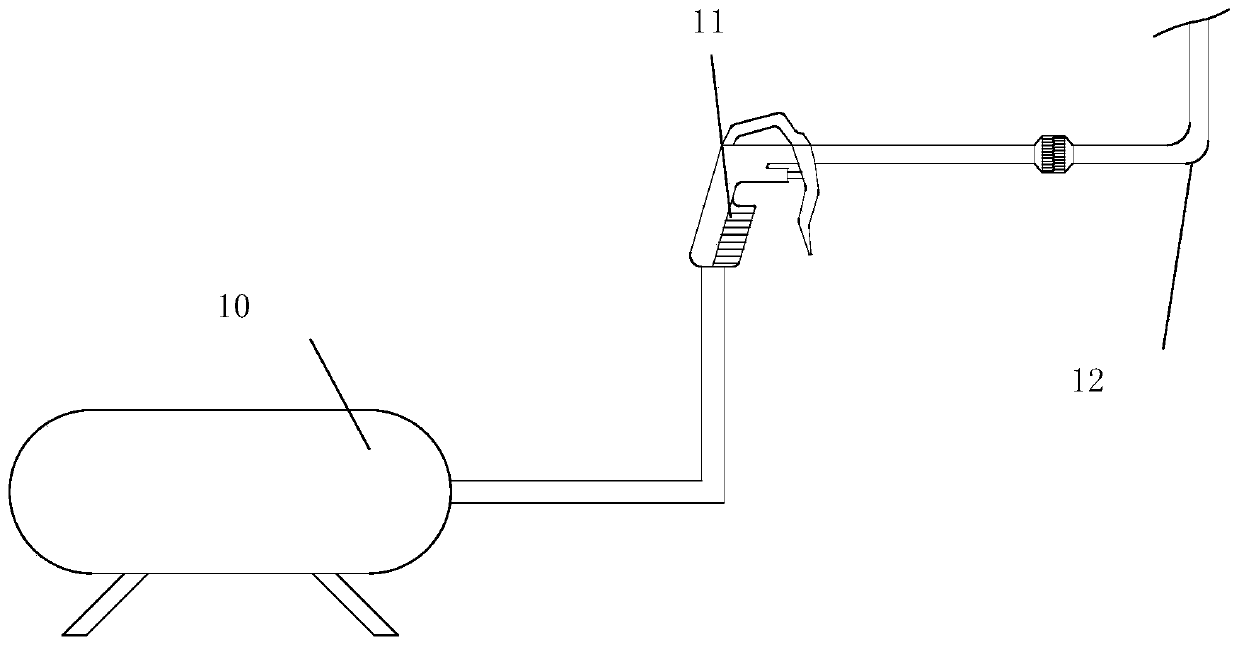

[0023] combine Figure 1-Figure 6 , an online and in-position detection system for tool damage in a clean cutting environment of the present invention, comprising an online prediction and identification system, an in-position detection system, a data acquisition card 15, an image acquisition card 13, a cleaning system, and a computer 14;

[0024] The online prediction and recognition system includes a vibration sensor 1, a voltage sensor 2, a force sensor 3, a current sensor 4, and an acoustic emission sensor 5; the vibration sensor 1 is installed near the cutting position of the machine tool machining center 6 or at the tool handle, Used for real-time measurement of vibration near the cutting position during machine tool processing; the voltage sensor 2 and current sensor 4 are installed at the control cabinet of the machine tool machining ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com